EL92-180/205/230

62. - Contents

KN007CGB_F

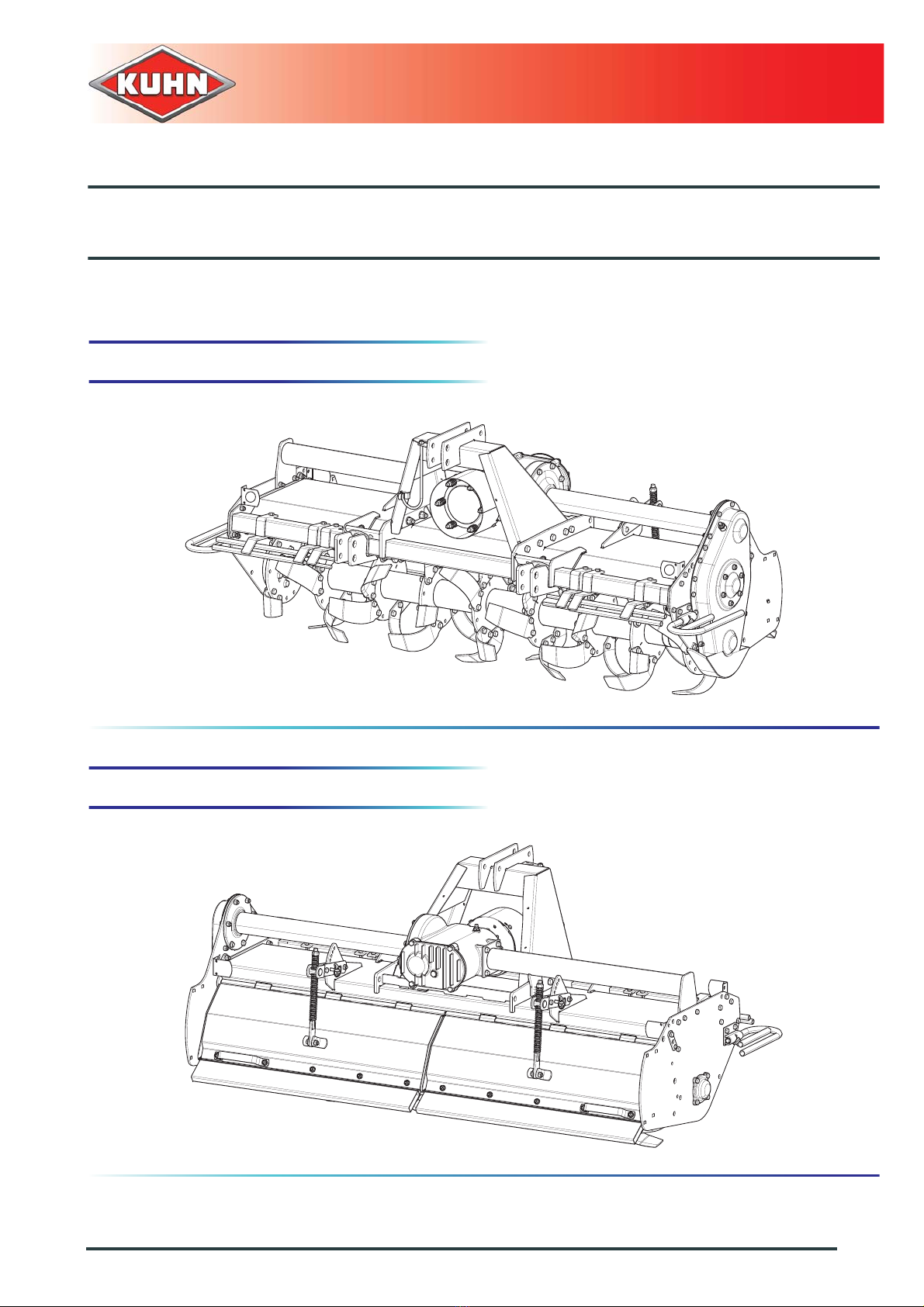

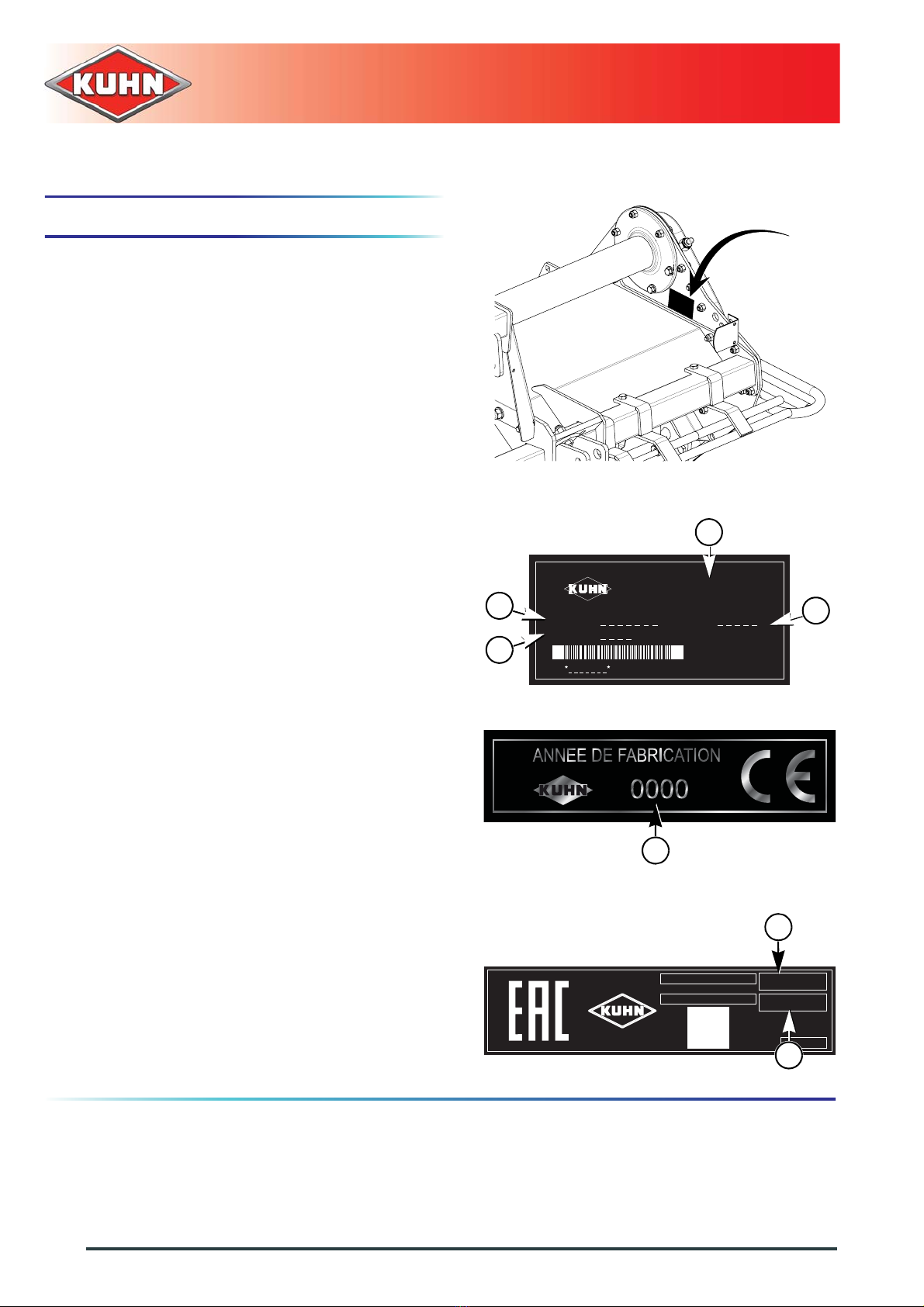

Power tiller

9. Optional equipment......................................................................................................58

9.1 32x38-8 spline yoke....................................................................................................................... 58

9.2 Side discs ......................................................................................................................................58

9.2.1 Working depth adjustment................................................................................................ 58

9.3 Track eradicators with flexible tines...............................................................................................59

9.3.1 Fitting................................................................................................................................ 59

9.3.2 Coupling and uncoupling.................................................................................................. 60

9.3.3 Adjustments in working position .......................................................................................61

9.3.4 Maintenance..................................................................................................................... 62

9.4 Set of gearwheels.......................................................................................................................... 62

9.4.1 Rotor speed adjustment ................................................................................................... 62

9.5 Lighting and signalling ...................................................................................................................64

9.5.1 Coupling and uncoupling.................................................................................................. 64

9.6 Lateral signalling equipment (for France) ......................................................................................65

9.7 USA signalling equipment.............................................................................................................. 65

9.8 Roller arm ...................................................................................................................................... 65

9.9 Clamp (Rotors) .............................................................................................................................. 66

10. Maintenance and storage ............................................................................................67

10.1 Frequency chart............................................................................................................................. 67

10.2 Cleaning the machine.................................................................................................................... 68

10.3 Lubrication ..................................................................................................................................... 68

10.3.1 Primary PTO shaft............................................................................................................69

10.3.2 Emptying........................................................................................................................... 69

10.3.3 Greasing...........................................................................................................................72

10.4 Maintenance .................................................................................................................................. 72

10.4.1 Headstock.........................................................................................................................72

10.4.2 Tool replacement..............................................................................................................72

10.5 Storage .......................................................................................................................................... 75

10.5.1 At the end of each season................................................................................................75

10.5.2 At the start of each season...............................................................................................75

10.5.3 Storage............................................................................................................................. 75

10.6 Dismantling and scrapping of the machine....................................................................................76

11. Troubleshooting guide.................................................................................................77

12. Appendix.......................................................................................................................79

12.1 Calculating the load on an axle...................................................................................................... 79

13. Limited Warranty ..........................................................................................................85