2. - Contents

GF8702

3

KN142BGB G

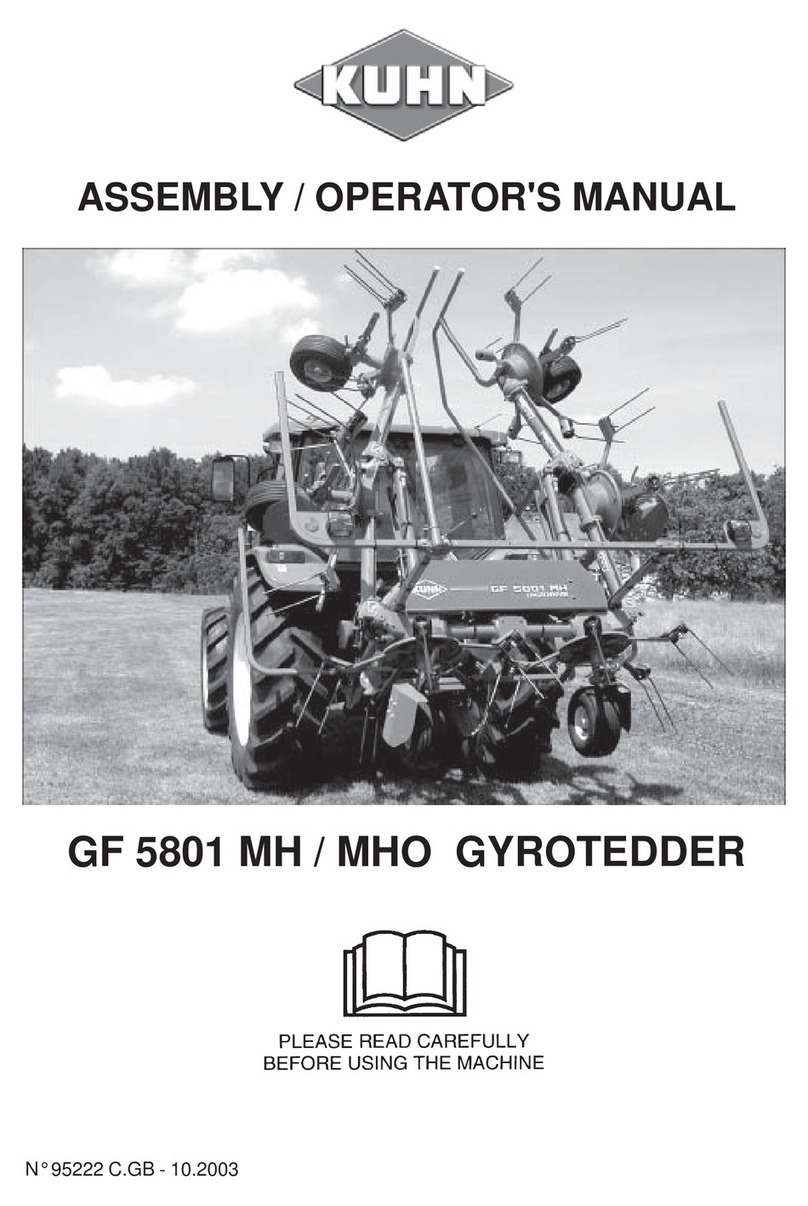

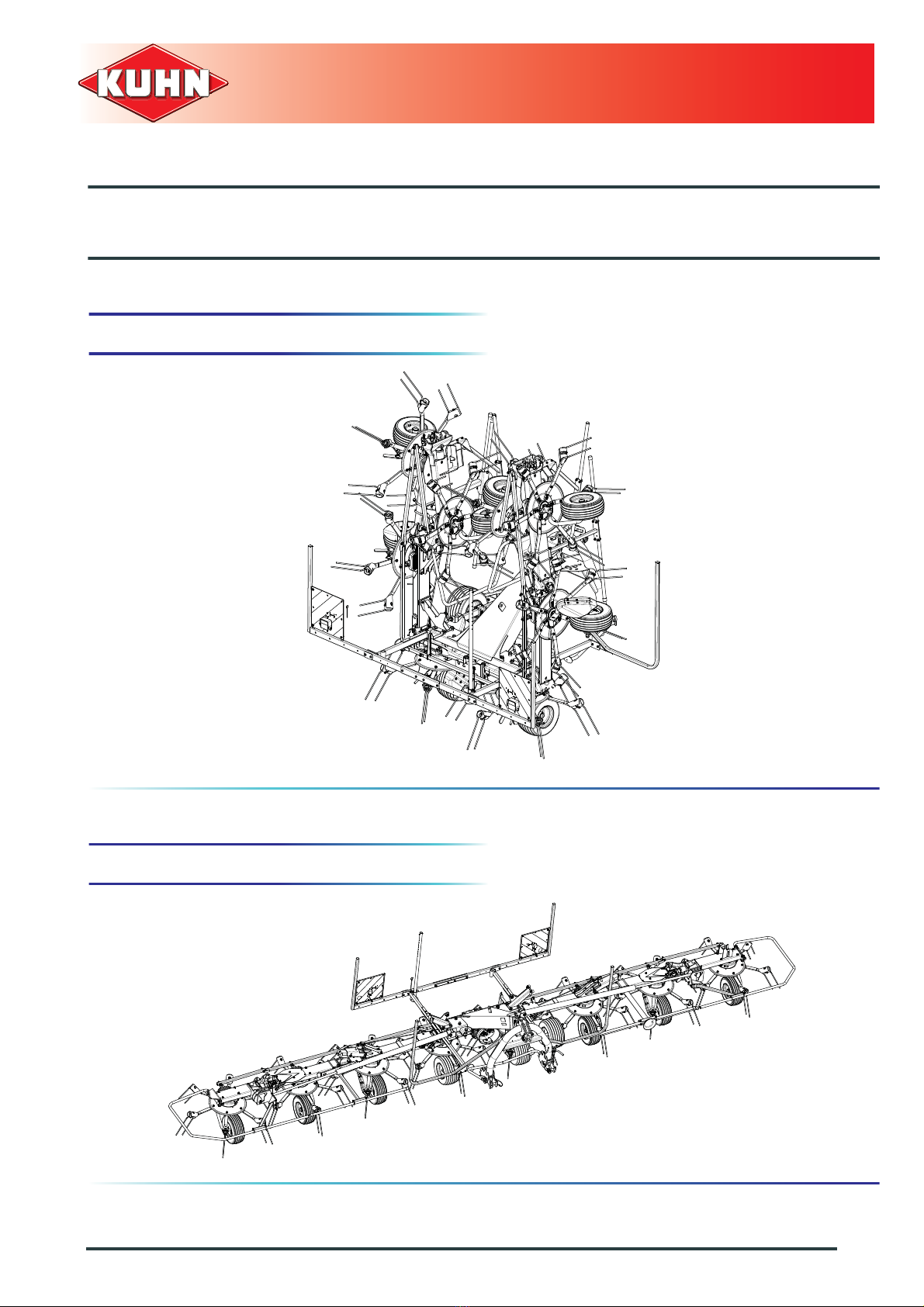

Gyrotedder

4.4 Road safety equipment and recommendations............................................................................. 27

4.4.1 Instructions specific to France.......................................................................................... 29

4.4.2 Tyre pressure ................................................................................................................... 30

4.5 Likely critical failures...................................................................................................................... 30

4.6 Incorrect use of the machine by the user ...................................................................................... 30

4.7 Limit state criteria........................................................................................................................... 31

5. Machine specifications................................................................................................ 32

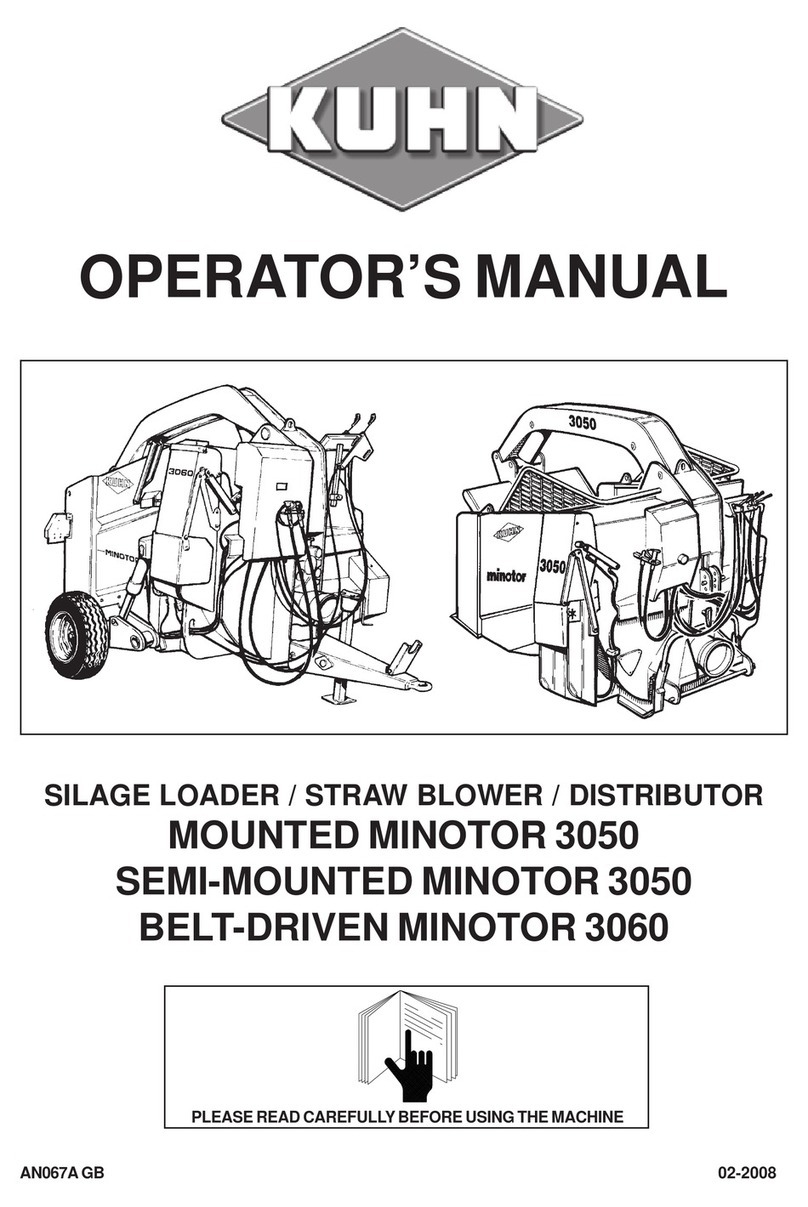

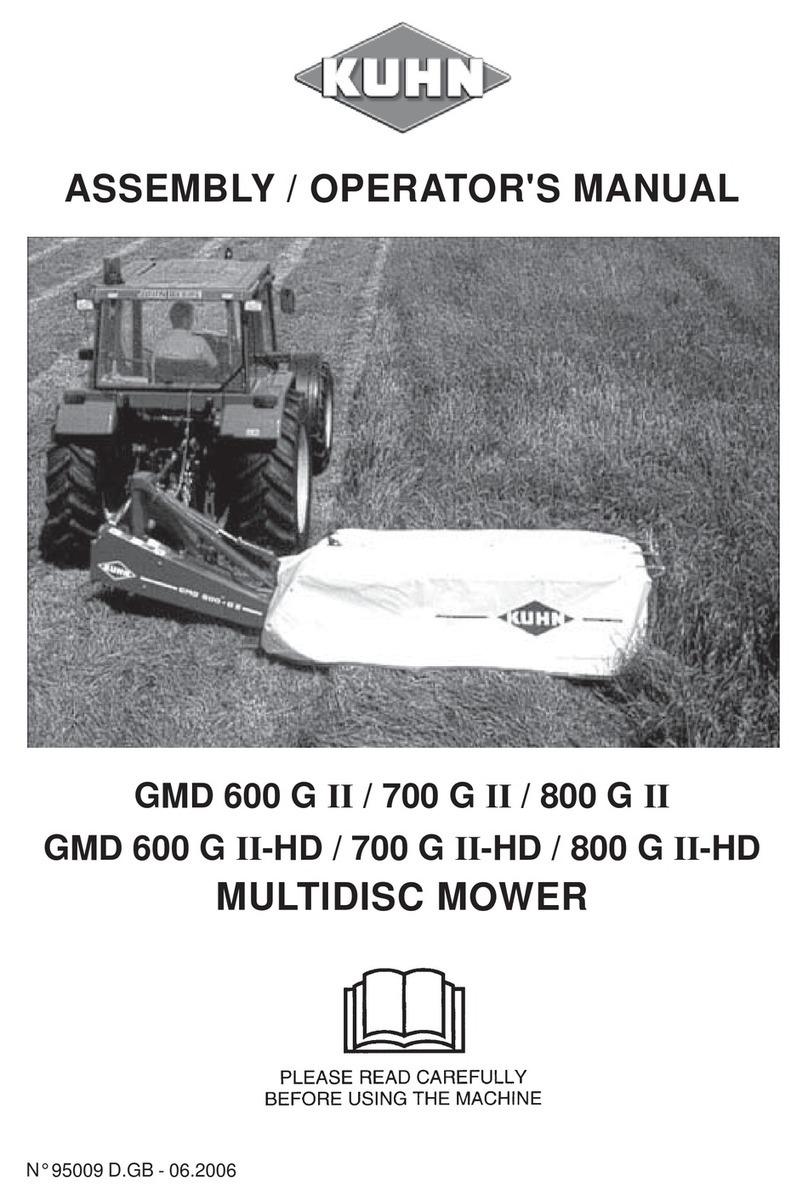

5.1 Description and glossary ............................................................................................................... 32

5.2 Technical specifications................................................................................................................. 33

5.2.1 Designated parameters.................................................................................................... 33

5.3 Required equipment...................................................................................................................... 34

5.3.1 Primary PTO shaft............................................................................................................ 34

5.3.2 Lighting and signalling...................................................................................................... 34

5.4 Sound levels.................................................................................................................................. 35

6. Putting into service...................................................................................................... 36

6.1 Description of control elements ..................................................................................................... 36

6.2 Coupling and uncoupling............................................................................................................... 36

6.2.1 Description of coupling elements ..................................................................................... 36

6.2.2 Preparing the tractor......................................................................................................... 37

6.2.3 Preparing the machine..................................................................................................... 39

6.2.4 Coupling the machine.......................................................................................................39

6.2.5 Hydraulic connections......................................................................................................41

6.2.6 Electrical connection ........................................................................................................ 41

6.2.7 Primary PTO shaft............................................................................................................ 42

6.2.8 Folding/unfolding sequence ............................................................................................. 44

6.2.9 Uncoupling the machine................................................................................................... 45

7. Instructions for transport............................................................................................ 48

7.1 Putting the machine into transport position ................................................................................... 48

7.2 Conformity with the road regulations............................................................................................. 50

7.3 Machine transport using transport means ..................................................................................... 51

8. Instructions for work................................................................................................... 52

8.1 Putting the machine into work position.......................................................................................... 52

8.2 Adjustments in working position .................................................................................................... 53

8.2.1 Pitch angle adjustment.....................................................................................................54

8.2.2 Work in oblique position...................................................................................................55

8.2.3 Adjustment of the travel range for work on slopes........................................................... 55

8.3 Machine use .................................................................................................................................. 57

8.3.1 Drive speed...................................................................................................................... 57