Table of contents

5

Table of c ontents

Preface .............................................................7

Target group of this operation manual 7

Training 7

Symbols used 8

Safety instructions .........................................9

For your safety 9

Safety decals 10

Who is allowed to operate the machine? 13

General 13

Hitching the machine 15

Hydraulics 16

Road transport 17

Operation 19

Unhitching the machine 21

Maintenance 22

Further prescriptions 23

Warranty and responsibility 23

Familiarize yourself with the machine ........24

General 24

Product description 24

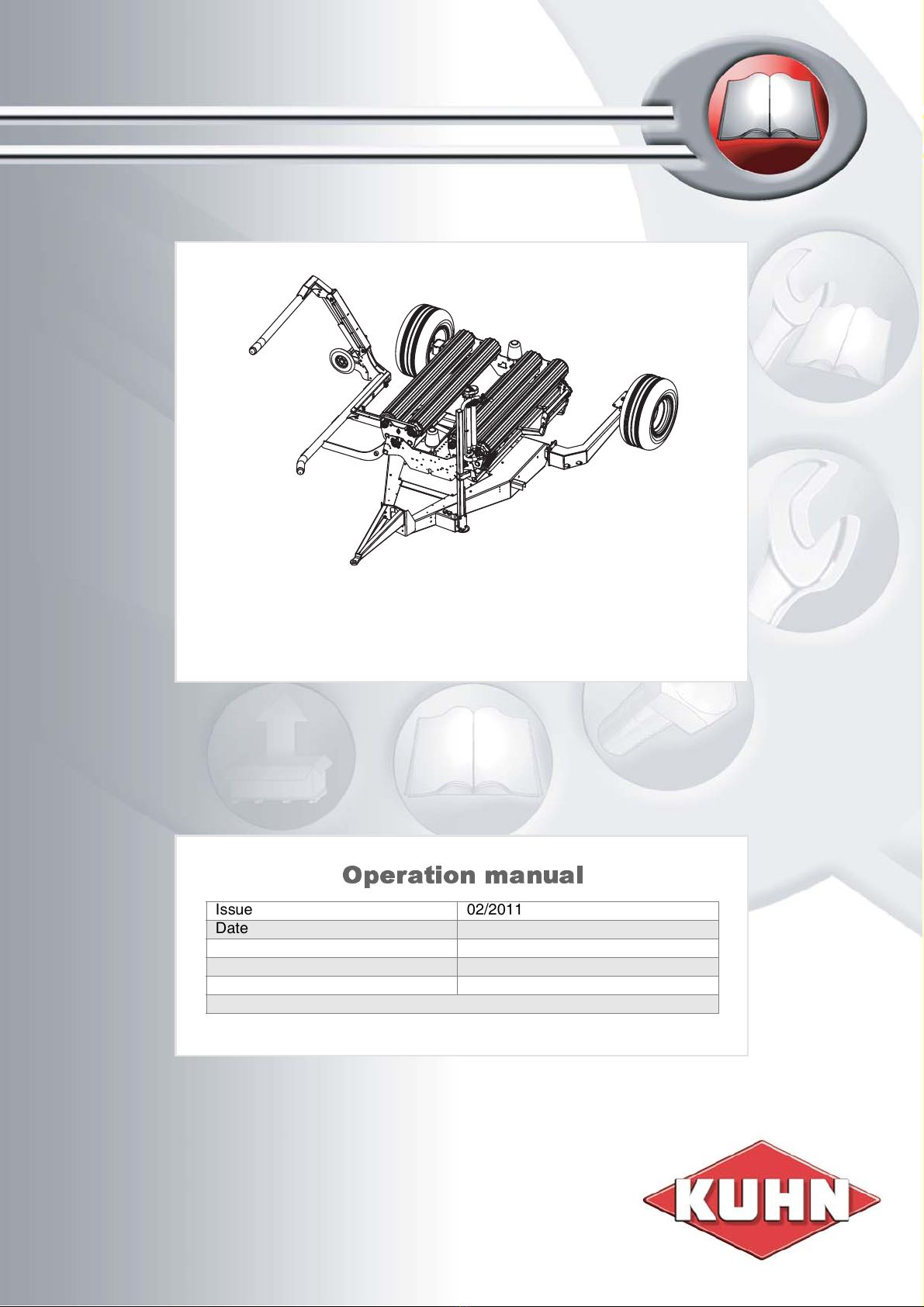

Main components overview 25

Technical specifications 26

Control systems 29

Delivery and assembly .................................32

Check the scope of delivery 32

Hitching the machine ................................... 33

Safety 33

General 33

Checklist 33

Hitching 34

Mechanical connections 35

Electronic connections 36

Hydraulic connections 37

Preparation for use .......................................39

Safety 39

Preparations 39

Support rollers adjustment 41

Pre-stretcher adjustment 42

Film installation 43

Loading arm disc adjustment 44

Loading arm adjustment 44

Checklist 44

Road transport .............................................. 45

Safety 45

General conditions 46

Empty the wrapping table 46

Wrapping table horizontal 47

Wrapping table in transport

position 47

Loading arm in transport position 48

Adjustable wheels in transport position 49

Hydraulic adjustable wheels[+] in

transport position 50

Checklist 50

Preparations at the field .............................. 51

Safety 51

Change settings 51

Set into operating mode 51

Wrapping table horizontal 52

Wrapping table in operating position 52

Loading arm in operating position 53

Adjustable wheels in operating position 54

Hydraulic adjustable wheels[+] in

operating position 54

Checklist 55

Operation ...................................................... 56

Safety 56

Required film wraps 57

Start position 58

Loading a bale 58

Wrapping procedure 60

Wrap and bale counter ................................. 63

General 63

Wrap and bale counter box 63

Parameters 64

Parameter settings 64

Electronic control system ........................... 66

General 66

Control panel 66

Parameter settings 69

Cleaning and care ........................................ 79

Safety 79

Caution 79

Cleaning 80

Parking and storage ..................................... 81

Safety 81

Unhitching the machine 81

After the season 81