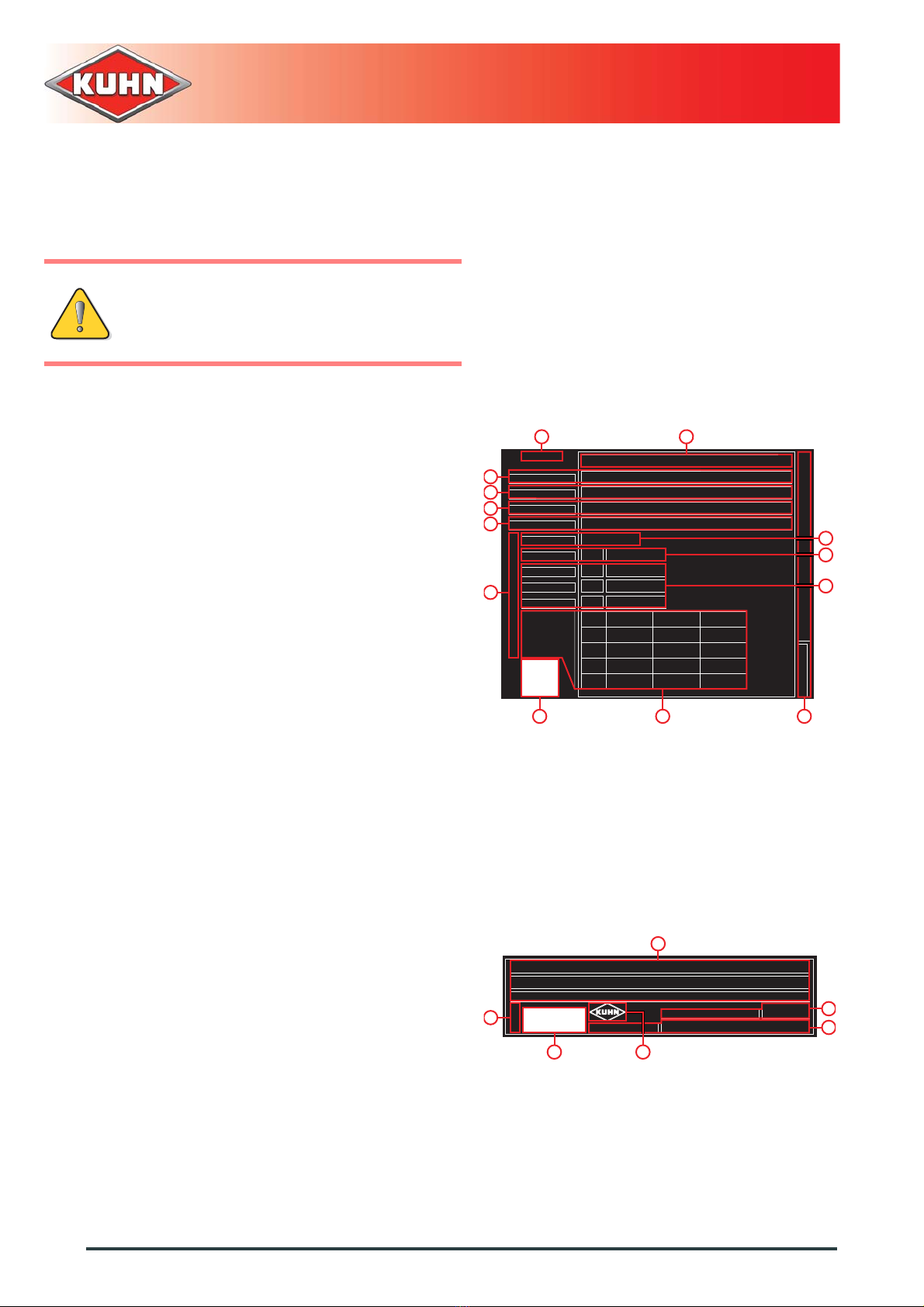

2. - Contents

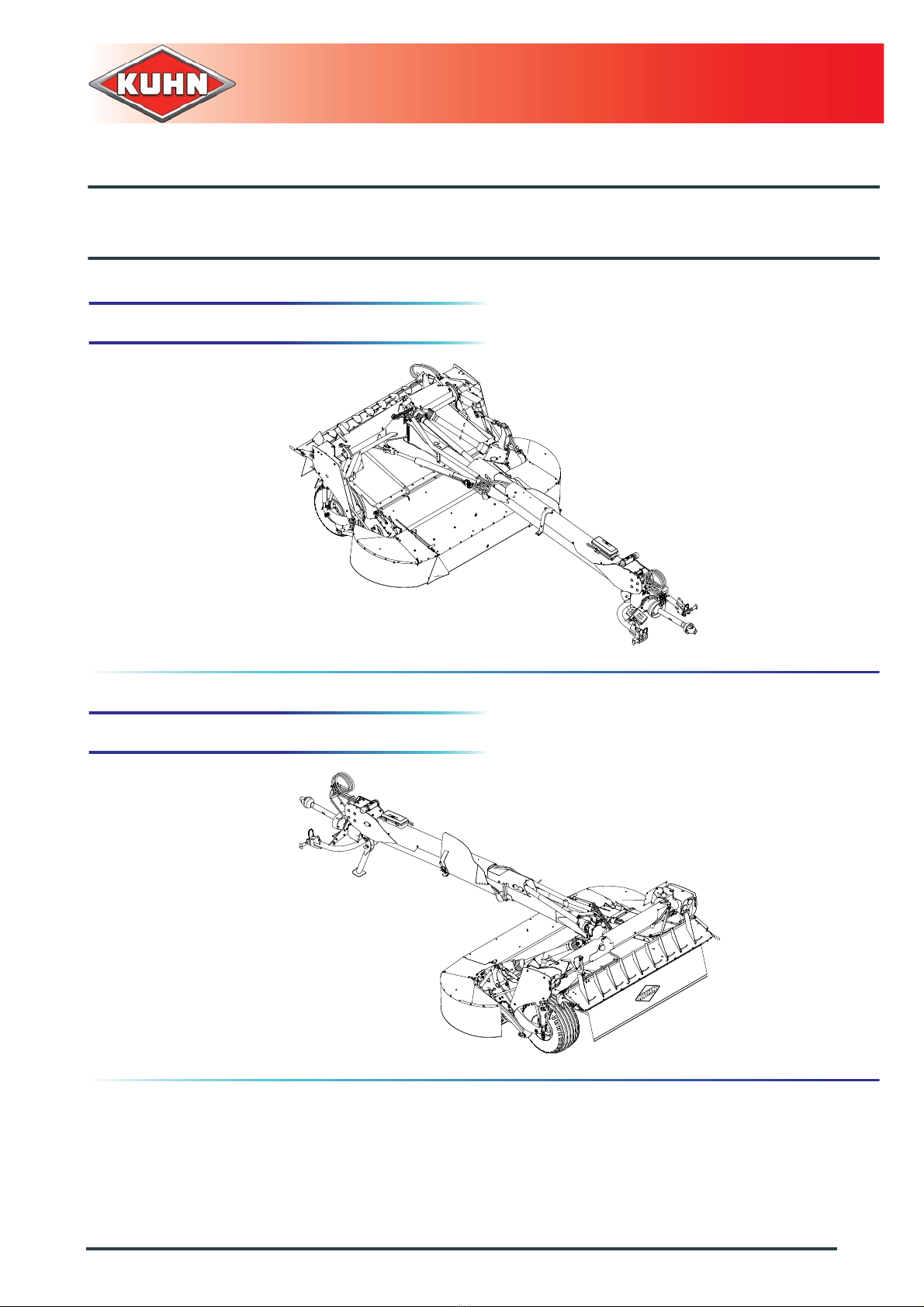

FC3160-3560-4060 TCD

5

KN284EGB_A

Mower conditioner

4.4 Road safety equipment and recommendations............................................................................. 28

4.4.1 Tyre pressure ................................................................................................................... 29

4.4.2 Instructions specific to France.......................................................................................... 29

4.4.3 Specific recommendations for the European Union......................................................... 30

4.5 Likely critical failures...................................................................................................................... 30

4.6 Incorrect use of the machine by the user ...................................................................................... 31

4.7 Limit state criteria........................................................................................................................... 31

4.8 Machine handling .......................................................................................................................... 31

5. Machine specifications................................................................................................ 33

5.1 Description and glossary ............................................................................................................... 33

5.1.1 Designated use of the machine........................................................................................ 36

5.2 Technical specifications................................................................................................................. 36

5.2.1 Designated parameters.................................................................................................... 36

5.3 Required equipment...................................................................................................................... 37

5.3.1 Check chains.................................................................................................................... 37

5.4 Sound levels.................................................................................................................................. 37

6. Putting into service...................................................................................................... 38

6.1 Description of control elements ..................................................................................................... 38

6.2 Coupling and uncoupling............................................................................................................... 39

6.2.1 Description of coupling elements ..................................................................................... 39

6.2.2 Prevention against unauthorised use............................................................................... 39

6.2.3 Preparing the tractor......................................................................................................... 39

6.2.5 Hydraulic connections......................................................................................................42

6.2.6 Electrical connections....................................................................................................... 43

6.2.7 Fit the check chains.......................................................................................................... 43

6.2.8 Primary PTO shaft............................................................................................................ 43

6.2.9 Intermediate PTO shaft .................................................................................................... 45

6.2.10 Adjusting the machine...................................................................................................... 48

7. Instructions for transport............................................................................................ 50

7.1 Transport position.......................................................................................................................... 50

7.2 Putting the machine into transport position ................................................................................... 51

7.3 Conformity with the road regulations............................................................................................. 52

7.4 Machine transport using transport means ..................................................................................... 53

8. Instructions for work................................................................................................... 54

8.1 Putting the machine into work position.......................................................................................... 54

8.2 Adjustments in working position .................................................................................................... 55

8.2.1 Cutting height................................................................................................................... 55

8.2.2 Ground pressure .............................................................................................................. 57

8.2.3 Finger conditioning rotor speed........................................................................................ 58

8.2.4 Conditioning intensity....................................................................................................... 59

8.2.5 Swathing and wide spreading .......................................................................................... 60