GA6501

22. - Contents

KN255AGB F

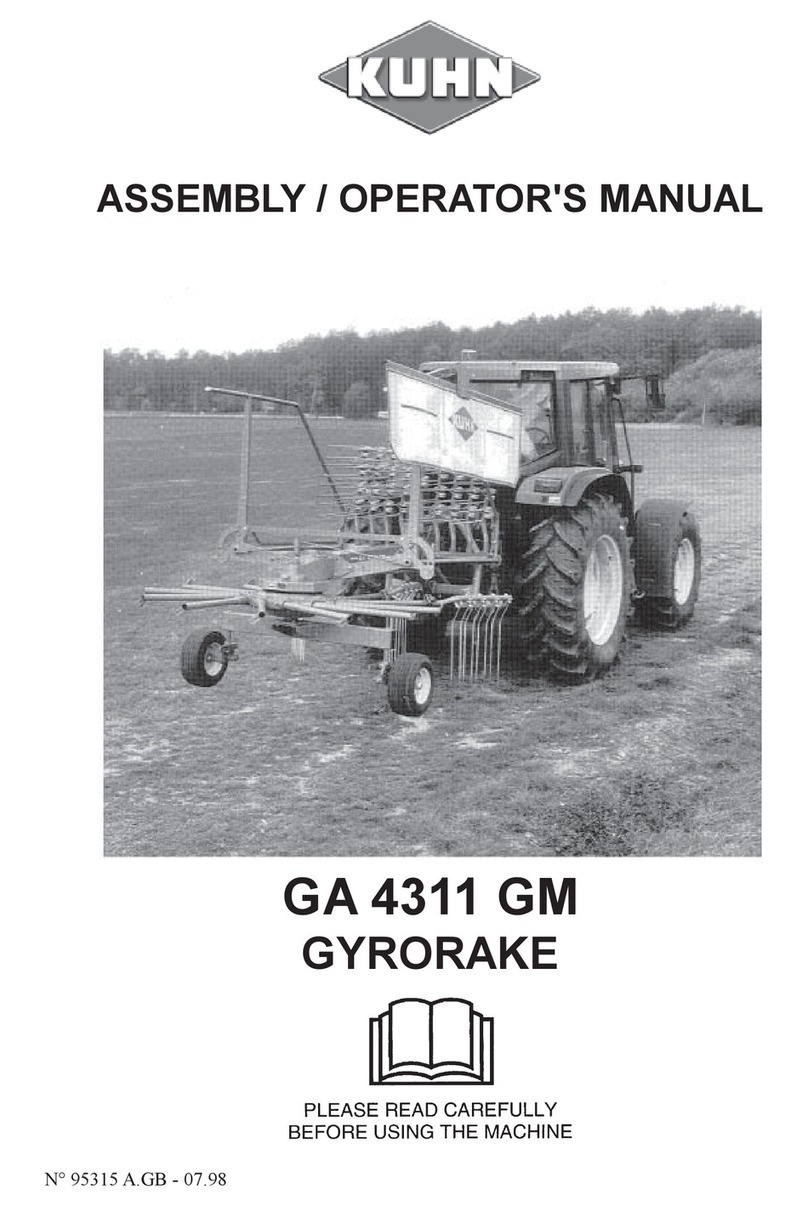

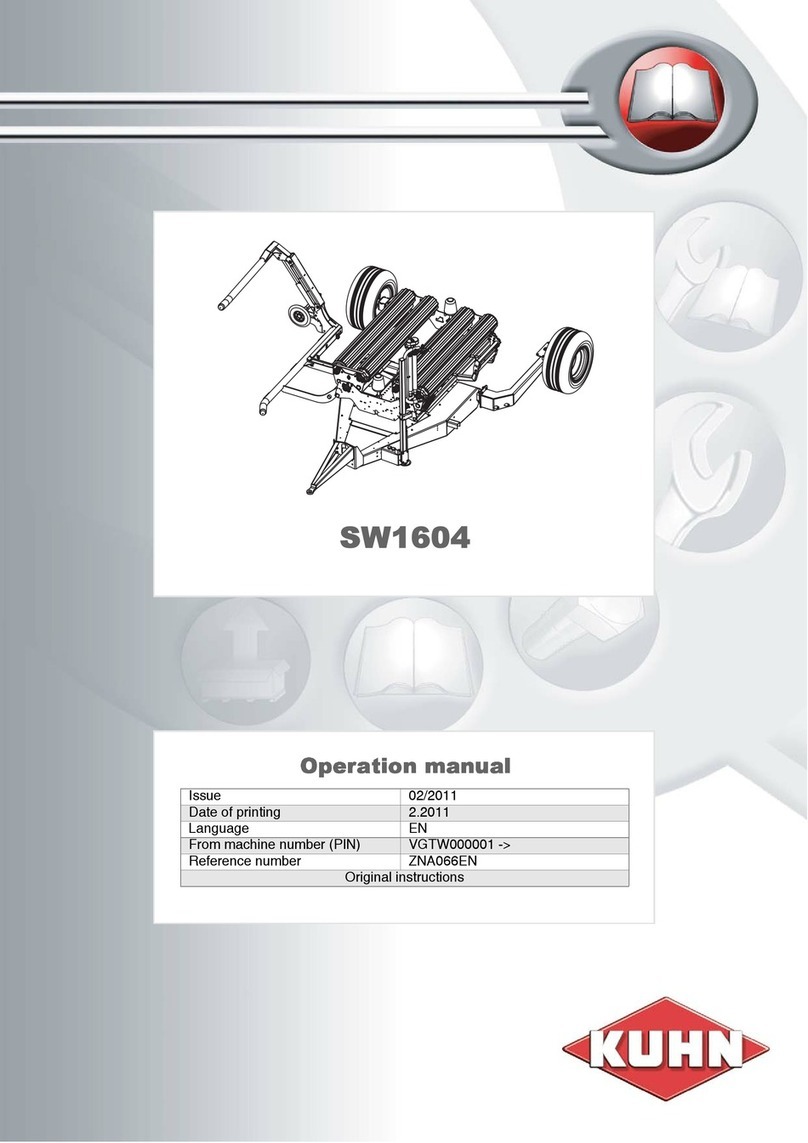

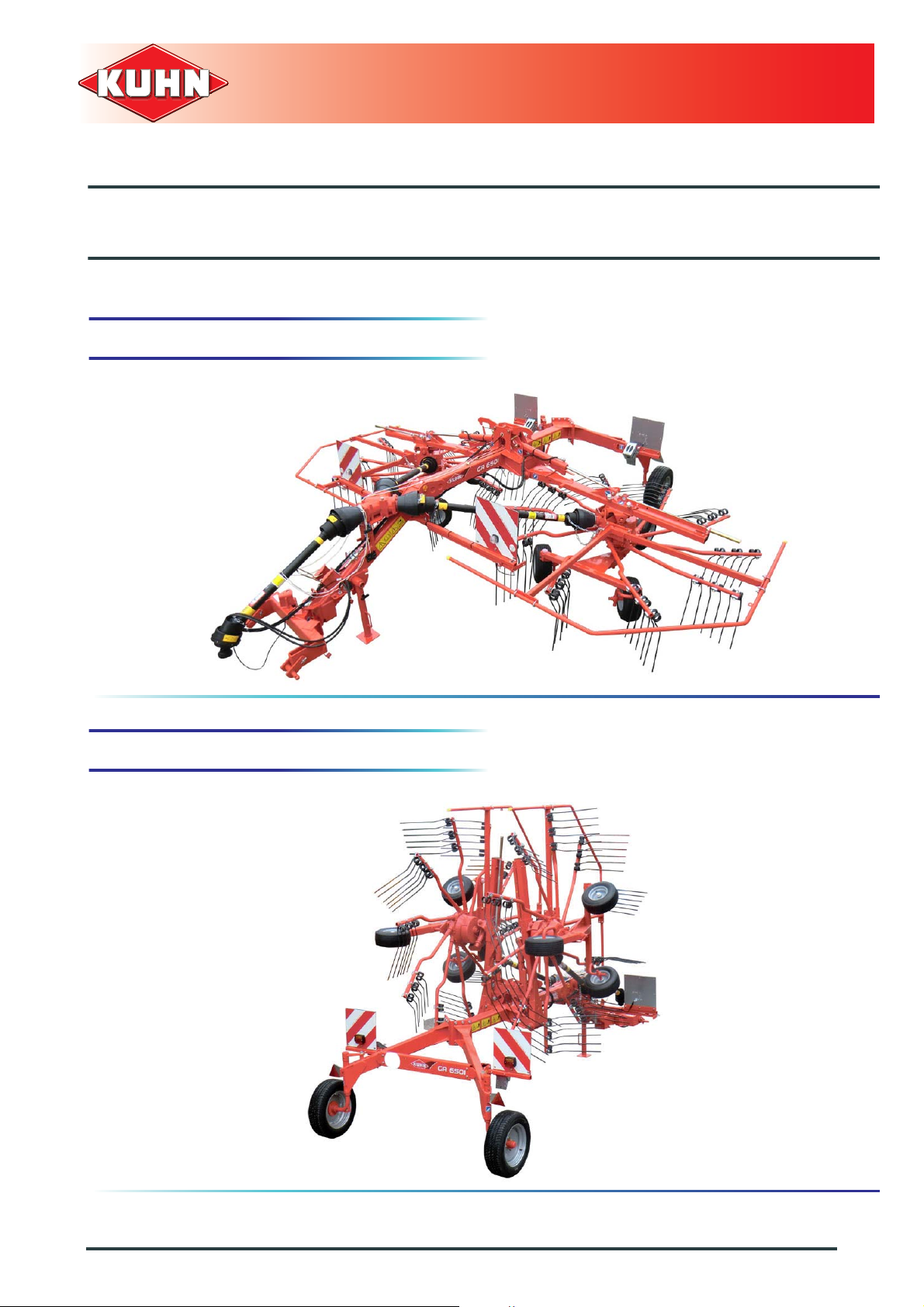

Gyrorake

2. Contents

1. Dear Owner .....................................................................................................................1

2. Contents..........................................................................................................................2

3. Identification of the machine.........................................................................................5

3.1 Front view (working position)........................................................................................................... 5

3.2 Rear view (transport position)..........................................................................................................5

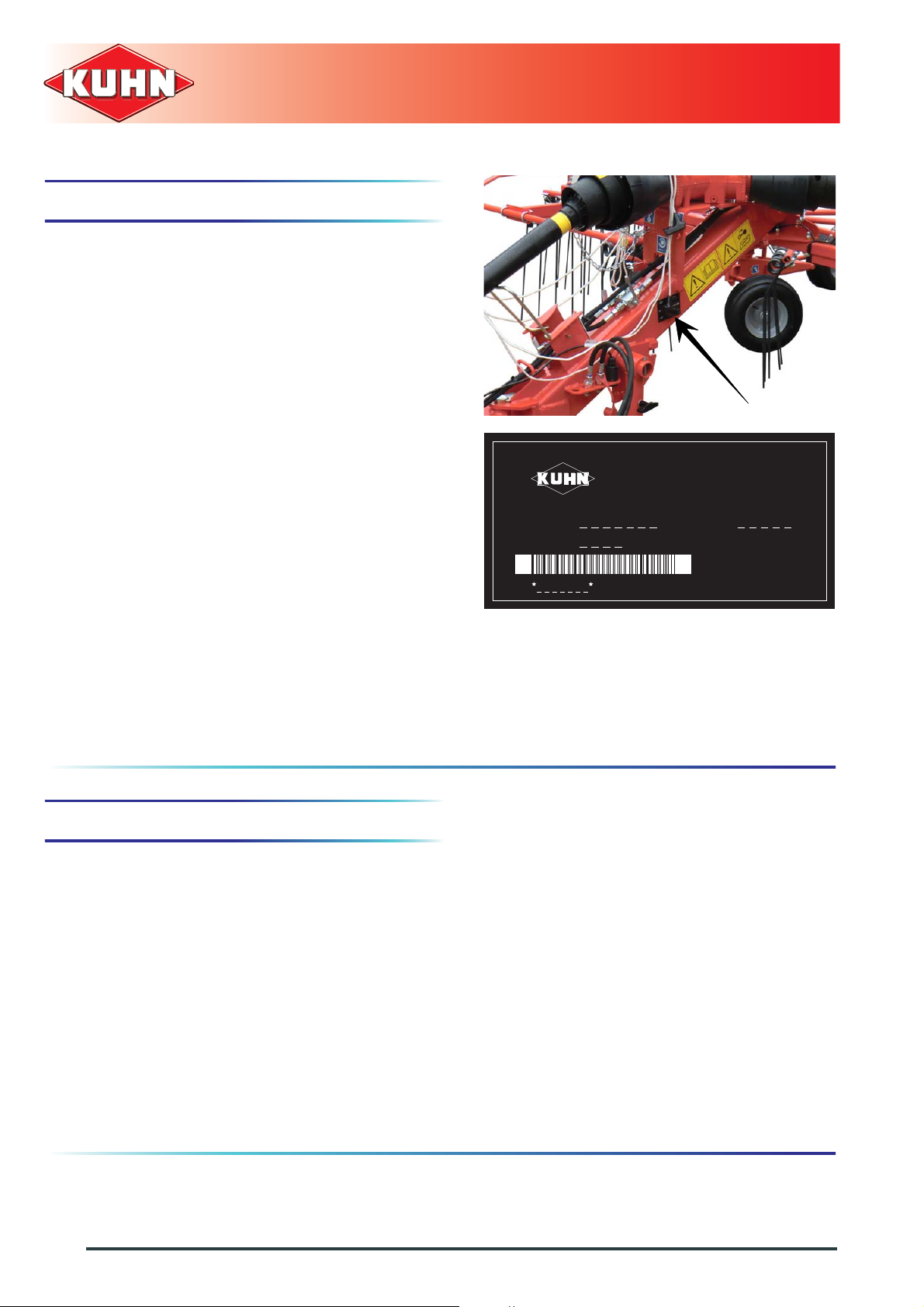

3.3 Model identification plate ................................................................................................................. 6

3.4 Optional equipment.......................................................................................................................... 6

4. Safety...............................................................................................................................7

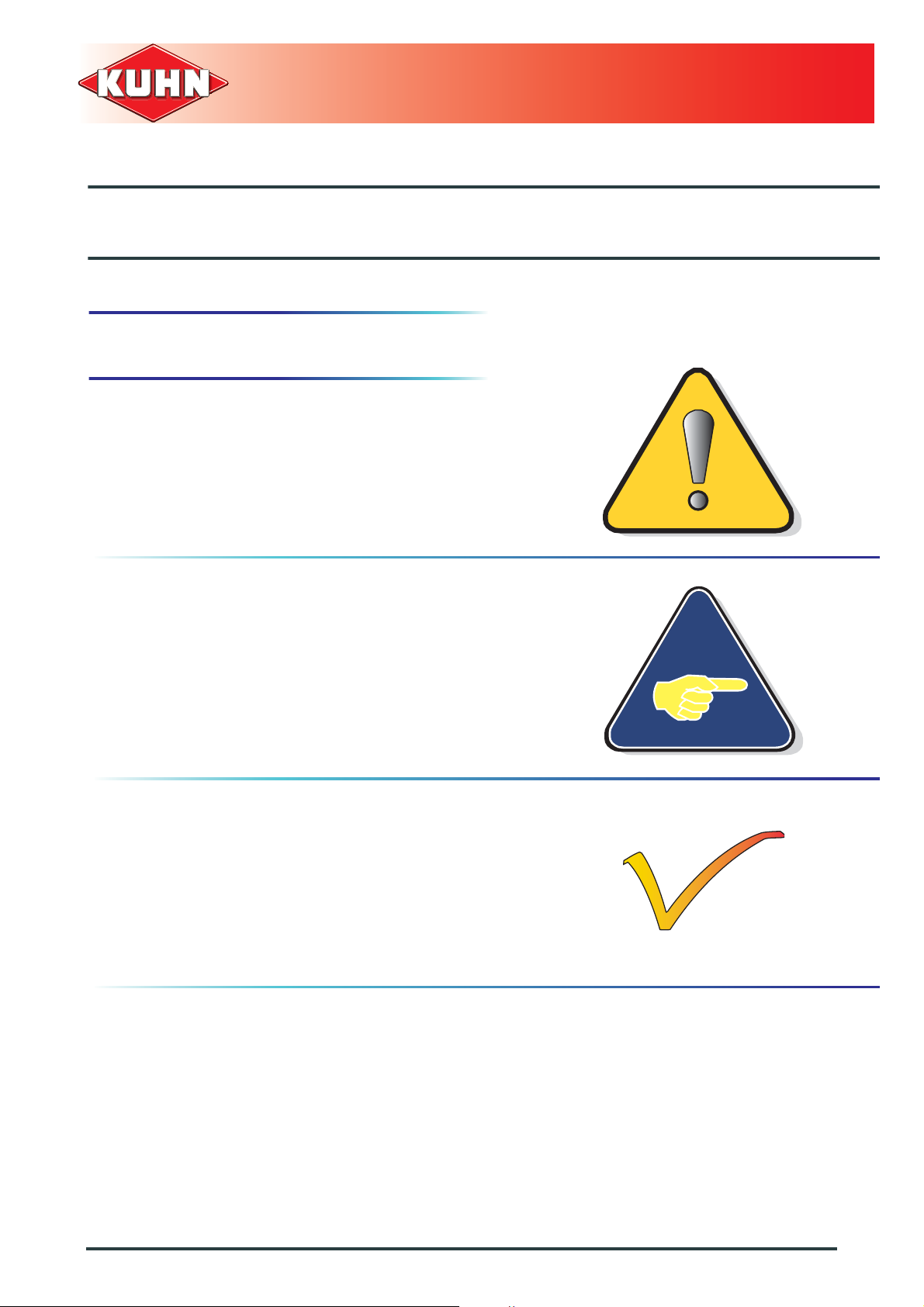

4.1 Description of symbols used in this document.................................................................................7

4.2 Safety instructions ...........................................................................................................................8

4.2.1 Introduction......................................................................................................................... 8

4.2.2 Read and follow the safety instructions..............................................................................8

4.2.3 Precautions to be taken before carrying out any operations on the machine..................... 8

4.2.4 Precautions to take before using the machine ................................................................... 9

4.2.5 Precautions when driving ...................................................................................................9

4.2.6 Precautions when driving on public roads........................................................................10

4.2.7 Maximum speed................................................................................................................11

4.2.8 Precautions when coupling...............................................................................................12

4.2.9 Hydraulic circuit................................................................................................................12

4.2.10 PTO shaft..........................................................................................................................13

4.2.11 Precautions during manoeuvres....................................................................................... 14

4.2.12 Remote controlled components........................................................................................15

4.2.13 Tyres.................................................................................................................................15

4.2.14 Safety decals.................................................................................................................... 15

4.2.15 Waste disposal .................................................................................................................15

4.2.16 Precautions for maintenance and repair work.................................................................. 16

4.2.17 Projection of stones and foreign objects........................................................................... 16

4.2.18 Precautions for machine use............................................................................................ 17

4.3 Location and description of safety decals on the machine ............................................................ 18

4.3.1 Location of safety decals..................................................................................................18

4.3.2 Description of safety decals.............................................................................................. 19

4.4 Road safety equipment and recommendations ............................................................................. 21

4.4.1 Tyre pressure.................................................................................................................... 22

4.4.2 Instructions specific to France.......................................................................................... 22