Kverneland 3124 User manual

Other Kverneland Farm Equipment manuals

Kverneland

Kverneland a-drill User manual

Kverneland

Kverneland Exacta-TL-GEOSPREAD GS3 User manual

Kverneland

Kverneland 2316M Operating manual

Kverneland

Kverneland Vicon ANDEX 694 EVO User manual

Kverneland

Kverneland Qualidisc Farmer User manual

Kverneland

Kverneland EO User manual

Kverneland

Kverneland CTC 427 User manual

Kverneland

Kverneland Vicon PS225 User manual

Kverneland

Kverneland Vicon Andex 774 User manual

Kverneland

Kverneland Taarup 4228 LT User manual

Kverneland

Kverneland Vicon RF 2235 User manual

Kverneland

Kverneland AD User manual

Kverneland

Kverneland CLC Evo User manual

Kverneland

Kverneland CLG-II User manual

Kverneland

Kverneland Vicon Andex 724 User manual

Kverneland

Kverneland Miniair Nova User manual

Kverneland

Kverneland Kultistrip User manual

Kverneland

Kverneland 150 Series User manual

Kverneland

Kverneland 41-L Series User manual

Kverneland

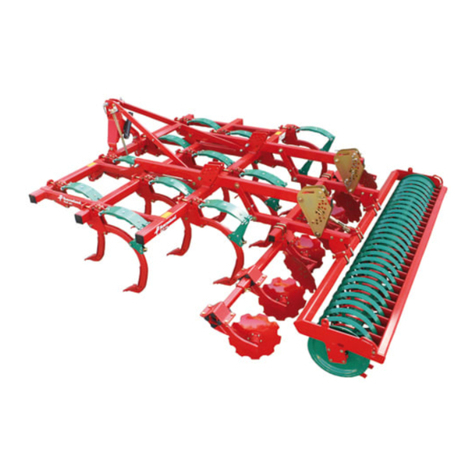

Kverneland CLC PRO User manual

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions