2Lindab reserves the right to make changes without prior notice

2020-04-21

Lindab reserves the right to make changes without prior notice

2020-04-21

Installation instruction Premum/Premax

lindab | we simplify construction

1 Content and symbols

1.1 Content

1. Content and symbols..........................................2

1.1 Content....................................................................... 2

1.2 Symbols ..................................................................... 3

2. Control of delivery .............................................3

2.1 Before starting............................................................ 3

2.2 Safe operation............................................................ 3

2.3 Receipt of goods........................................................ 3

2.4 Unloading of goods....................................................3

2.5 Handling / Carrying.................................................... 3

2.6 Tools ........................................................................... 4

2.7 Installation .................................................................. 4

2.8 Where to find additional instructions or technical

documentation........................................................... 4

2.9 Cleaning after assembly/before commissioning....... 4

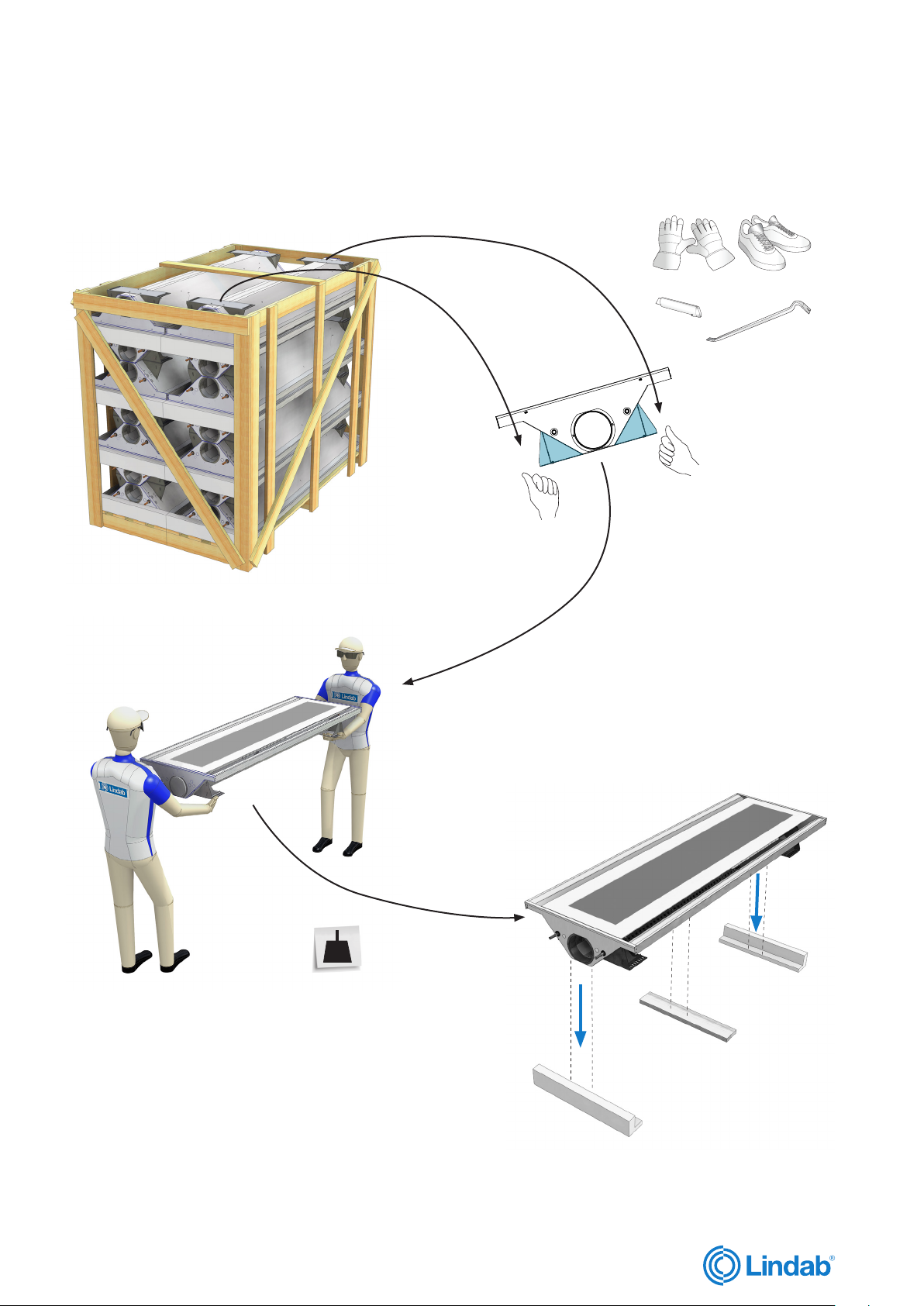

2.10 Packing, unpacking guideline .................................. 5

2.11 Product labelling....................................................... 6

2.12 Order code ............................................................... 7

2.13 Order code examples............................................... 7

2.14 Label ......................................................................... 7

2.15 Contents of order ..................................................... 8

2.16 Plus features............................................................. 8

2.16.1 Inlet faceplates....................................................... 8

2.16.2 Outlet front grilles........................................................ 8

2.16.3 Integrated valves ................................................... 8

2.16.4 Integrated Actuators.............................................. 8

2.16.5 Integrated Regula components............................. 8

2.16.6 Airguides................................................................ 8

2.16.7 Heating .................................................................. 8

2.17 Accessories .............................................................. 8

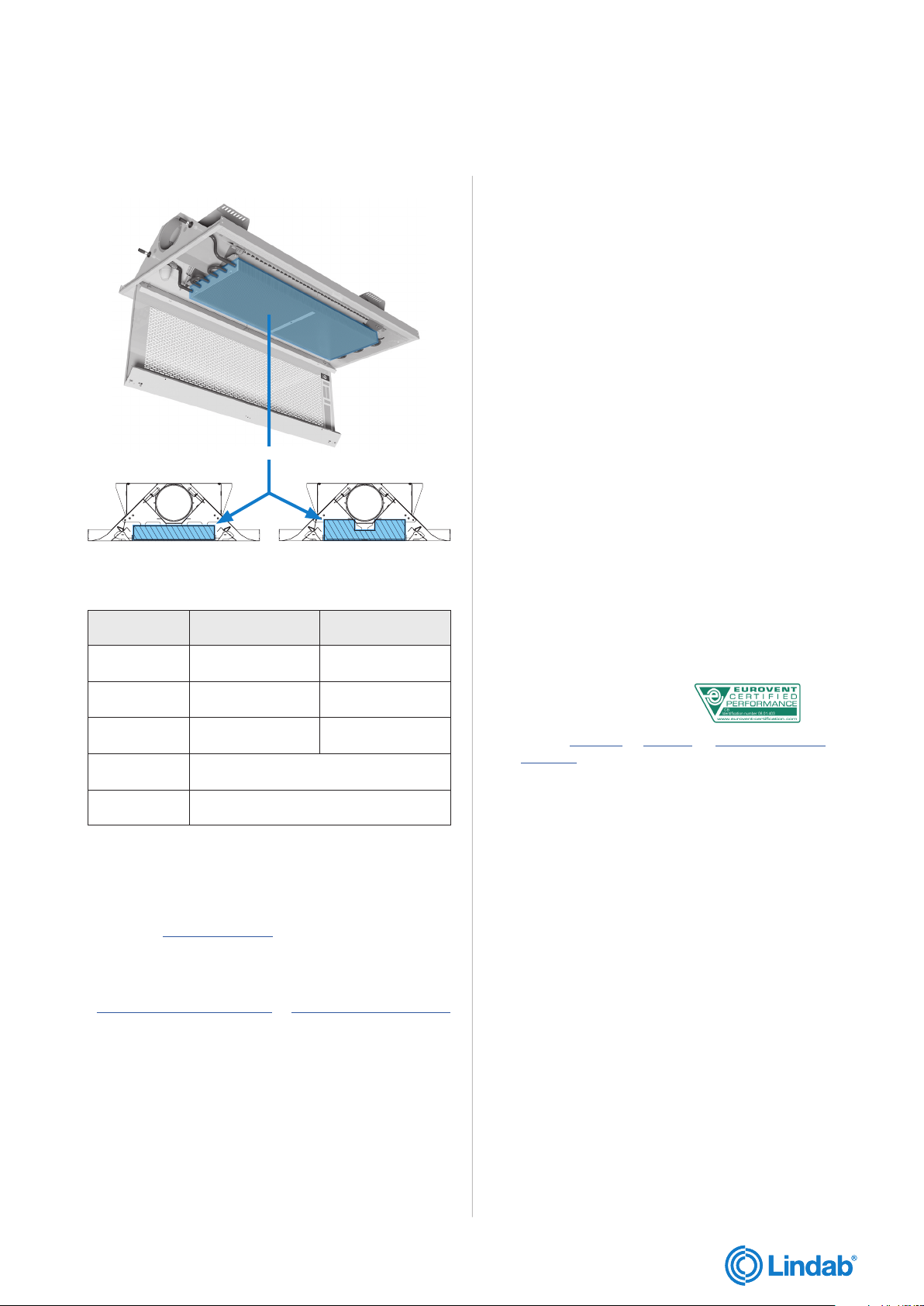

3. Product specification.........................................9

3.1 Product description.................................................... 9

3.2 Dimensions ................................................................ 9

3.3 Premum / Premax.................................................... 10

3.4 Material data ............................................................ 10

3.5 Environmental Declarations..................................... 10

3.6 Pressure class.......................................................... 10

3.7 Water quality ............................................................ 10

3.8 Air quality ................................................................. 10

3.9 Capacity test............................................................ 10

4 Connections ...................................................... 11

4.1 Water connections ................................................... 11

4.1.1 Befo re installation .................................................. 11

4.1.2 Push on fitting ....................................................... 12

4.1.3 Compression fitting............................................... 12

4.1.4 Flexible hoses........................................................ 12

4.1.5 Additional Lindab accessories for water

connections ........................................................... 13

4.1.6 Possible connections water cooling

(2-pipe, standard).................................................. 14

4.1.7 Possible connections water cooling and

heating (4-pipe, plus feature) ................................ 15

4.2. Air connections ....................................................... 16

4.2.1 Air connection installation..................................... 16

4.2.2 Possible connections supply air........................... 16

4.2.3 Possible connections extract air .......................... 16

4.3 Possible combination of connections ..................... 16

4.4 Electrical connections ............................................. 17

4.4.1 Regula components on the beam......................... 17

4.4.2 Example 1: Wiring scheme with Regula

Connect multi........................................................ 18

4.4.3 Example 2: Wiring scheme with Regula

Connect basic....................................................... 18

4.4.4 Regula Connect on the beam............................... 19

4.4.5 Regula Secura on the beam ................................. 19

4.4.6 Valves and Actuators on the beam....................... 19

4.4.7 Regula Combi on/with the beam .......................... 19

4.4.8 Actuators............................................................... 19

5 Installation of product.......................................20

5.1 Handling of product ................................................. 20

5.2 Ceiling systems........................................................ 20

5.3 General installation principles ................................. 21

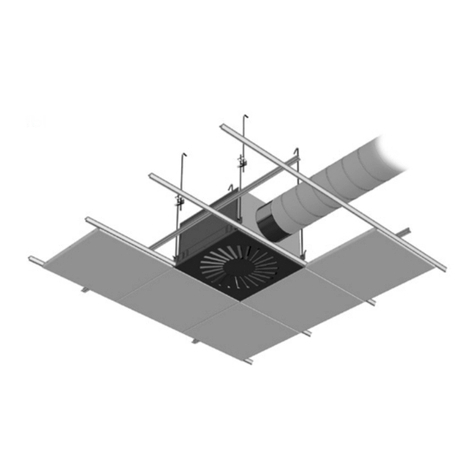

5.3.1 Recessed in suspended T-bar ceiling .................. 21

5.3.2 Exposed, sealed to the ceiling ............................. 21

5.3.3 Exposed, free hanging.......................................... 21

5.3.4 Free hanging above perforated or eggcrate

ceiling .................................................................... 21

5.3.5 Recessed in suspended (permanent)

ceiling .................................................................... 21

5.3.6 Recessed in suspended (permanent) ceiling

without cover flanges............................................ 21

5.4 Preparation for installation on the product.............. 22

5.5 Basics steps of installing the product ..................... 24

6 Adjustment and commissioning........................25

6.1 Airflow and pressure ................................................ 25

6.1.1 Jet cone adjustment pins ...................................... 25

6.1.2 Finding values for JetCone pins ........................... 27

6.1.3 Adjusting air flow and pressure with JetCone

pins......................................................................... 27

6.2 Adjustment of air distribution profile ....................... 29

6.3 Measuring air pressure and calculating the air

flow...........................................................................30

6.3.1 Measuring static nozzle pressure and air

pressure ................................................................30

6.3.2 Calculating the actual air flow .............................. 31

6.3.3 Changing the actual air flow ................................. 31

6.3.4 Changing the air distribution profile ..................... 31

6.3.5 Premum / Premax pressure / airflow diagrams ... 31

6.4 Water flow rate ......................................................... 32

6.4.1 Pre-setting of valves ............................................. 32

6.4.2 Balancing strategy ................................................ 32

7. Maintenance.....................................................33

7.1 Remove the outlet front grille ...................................33

7.2 Open inlet faceplate .................................................33

7.3 Opening inspection hatch........................................ 33

7.4 Lower battery ........................................................... 33

8 Accessories.......................................................34