4Design and function 36

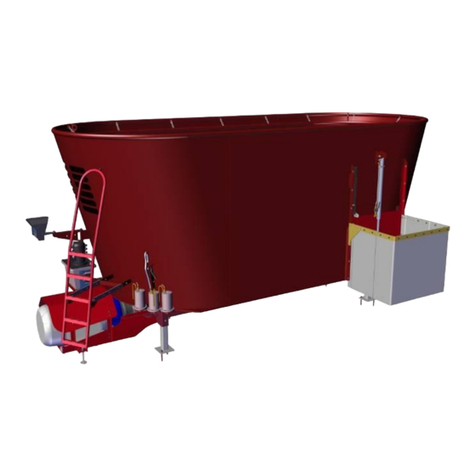

4.1 V-COMFORT Bedding –components at a glance 36

4.2 Receiving hopper 37

4.3 Dosing and mixing augers 38

4.4 Adjustable discharge opening 39

4.5 Conveyor belt 40

4.6 Doors 41

4.7 Mounting frame 42

4.8 Control panel 43

4.9 Hydraulic system 45

4.9.1 Hydraulic motor powering the conveyor belt 46

4.9.2 Hydraulic motor of the dosing and mixing augers 46

4.9.3 Electromagnetic lock valve 46

4.9.4 Flow control valve (optional) 47

4.9.5 Electrohydraulic control block (optional) 47

4.9.6 Hydraulic cylinders of the three-point mounting frame (optional) 48

4.10 Hydraulic hose lines 49

4.10.1 Coupling the hydraulic hose lines 49

4.10.2 Uncoupling the hydraulic hose lines 50

4.11 Safety devices and safeguards 51

4.11.1 Tipping sensor 51

4.11.2 Protective case - chain drive 52

4.11.3 Protective covers fitted in the doors 52

5Loading and unloading the machine 53

5.1 Loading and unloading using lifting devices 53

5.2 Loading and unloading using the tractor designated for operation with the

machine 53

6Commissioning 54

6.1 Traffic regulations 55

6.1.1 Traffic regulations applicable in Germany 55

6.2 Checking suitability of the tractor 55

6.2.1 Calculation of the actual values 55

6.3 Mounting the control panel to the tractor (optional) 56

6.4 Securing the tractor against unintended start-up and rolling away 57

6.5 Checking the machine for proper operation 57

7Coupling and uncoupling the machine 58

7.1 Coupling the machine 59

7.1.1 Coupling up to the three-point hydraulic system of a tractor 61

7.1.2 Coupling up to the quick-change device of a front, farmyard or wheel loader 62

7.2 Uncoupling the machine 63

7.2.1 Uncoupling from the three-point hydraulic system of a tractor 64

7.2.2 Uncoupling from the quick-change device of a front, farmyard or wheel loader 65

8Settings 66

8.1 Adjusting the bedding material quantity 66

8.1.1 Adjusting the opening width of the discharge opening 67

8.1.2 Adjusting the drive speed of the dosing and mixing augers 68

8.2 Adjusting the throw distance 70

8.3 Changing the throw direction on the V-COMFORT Bedding 1500/1700 71