5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1606 Rev.14 P. 1 / 5

INSTRUCTION MANUAL

RTD ALARM

(dual or quad alarm trip; eld-congurable) MODEL AS4R

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

This equipment is for use in general industrial environ-

ments, therefore may not be suitable for applications which

require higher level of safety (e.g. safety or accident preven-

tion systems) or of reliability (e.g. vehicle control or combus-

tion control systems).

For safety, installation and maintenance of this equipment

must be conducted by qualified personnel.

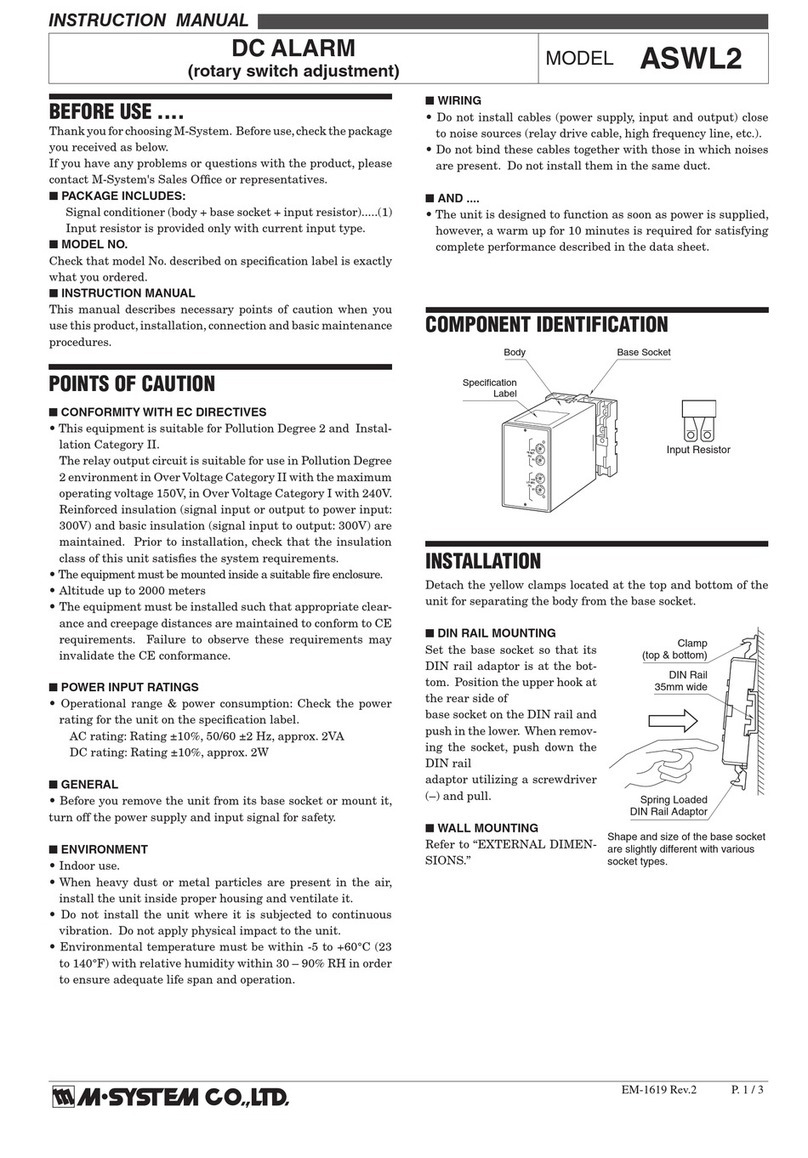

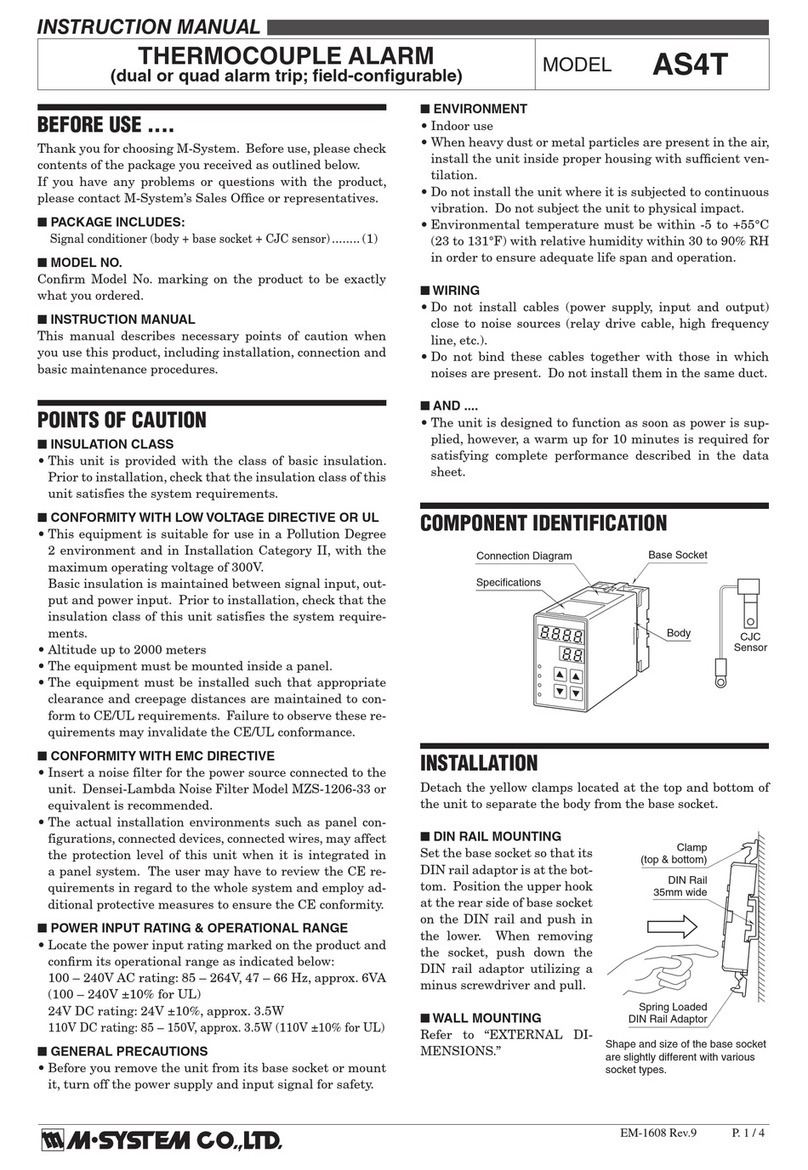

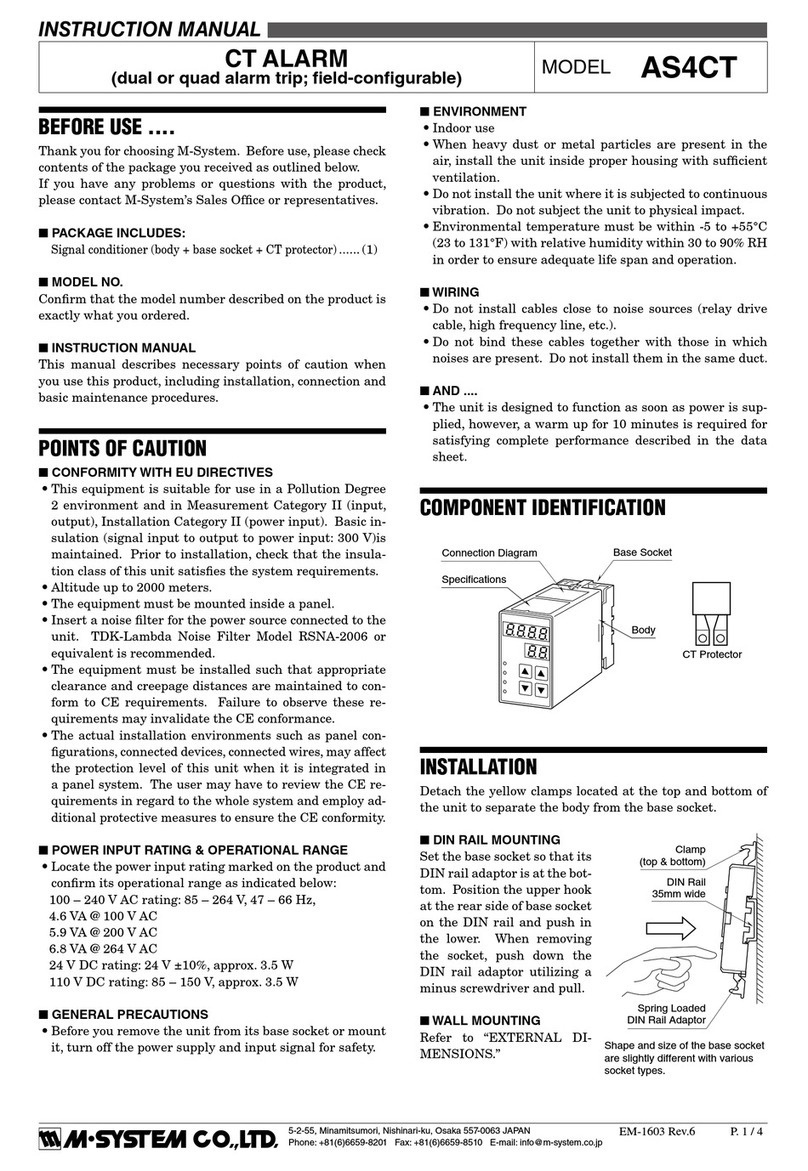

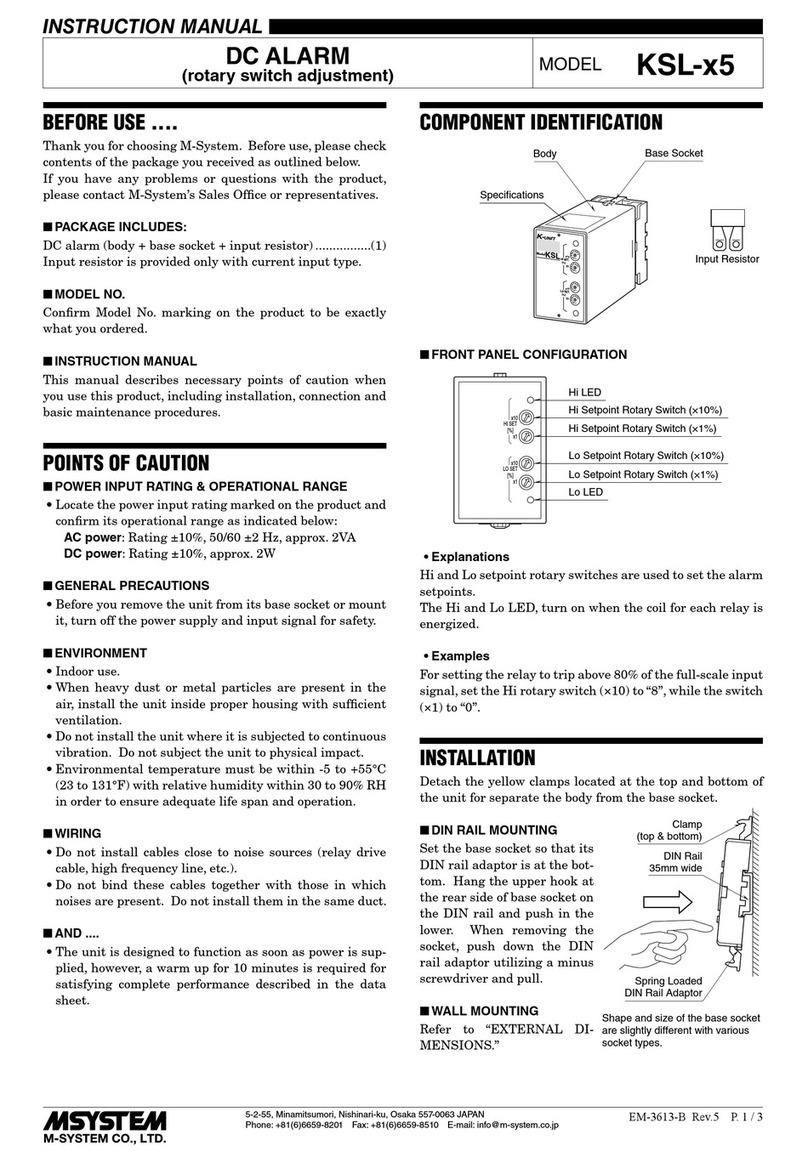

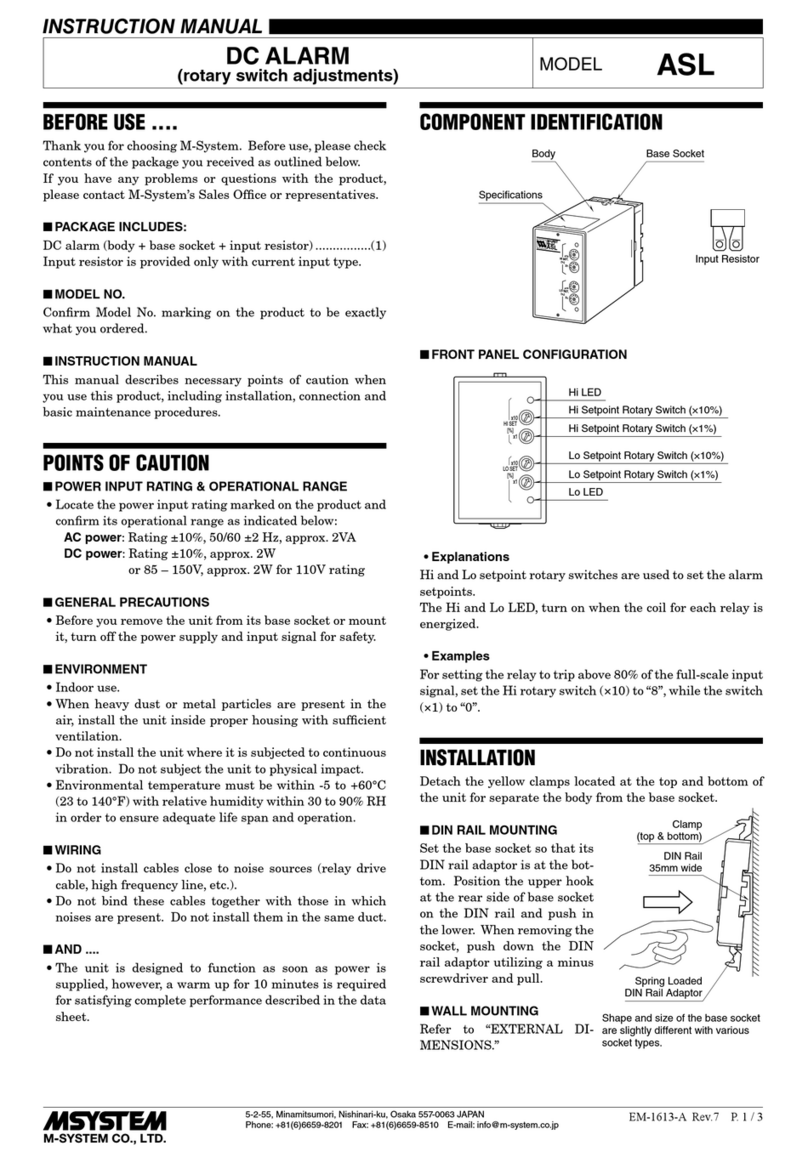

■PACKAGE INCLUDES:

RTD alarm (body + base socket).........................................(1)

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

■SYMBOLS USED ON THE PRODUCT AND IN THIS MANUAL

The symbol indicated on the equipment, means that the

user must refer to the related parts in the manual for safe

operation of the equipment. It is essential to read the in-

structions wherever the symbol appears in the manual.

WARNING: is reserved for conditions and actions that

can cause serious or fatal injury.

CAUTION: is reserved for conditions and actions that can

cause injury or instrument damage.

WARNING

■INSULATION CLASS

Basic insulation (Signal input or output to Power input:

300V) is maintained.

If insulation failure may result in equipment, hazardous

voltage (maximum 240V) may result to signal input and

then electric shock may cause.

Prior to installation, prepare supplemental insulation

(equivalent basic insulation) between signal input and ex-

ternal circuits.

CAUTION

■REGARDING SAFETY

If equipment is not used in a manner not specified by M-

System, the protection provided by the equipment may be

impaired.

■CONFORMITY WITH LOW VOLTAGE DIRECTIVE OR UL

• This equipment is suitable for Pollution Degree 2, Meas-

urement Category II (output, transient voltage 2500V)

and Installation Category II (transient voltage 2500V).

• Altitude up to 2000 meters.

• The equipment must be mounted inside a panel.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to con-

form to EU/UL requirements. Failure to observe these

requirements may invalidate the EU/UL conformance.

■CONFORMITY WITH EMC DIRECTIVE

• Insert a noise filter for the power source connected to the

unit. TDK-Lambda Noise Filter Model RSNA-2006 or

equivalent is recommended.

• The actual installation environments such as panel con-

figurations, connected devices, connected wires, may af-

fect the protection level of this unit when it is integrated

in a panel system. The user may have to review the CE

requirements in regard to the whole system and employ

additional protective measures to ensure the CE conform-

ity.

■SIGNAL INPUT

This terminal is used for signal input.

Do not connect or measure to the circuits including tran-

sient voltage 2500V.

Refer to “INPUT SPECIFICATIONS” in detail.

■OUTPUT TERMINAL

Never use the output terminal under any load that exceeds

the rated values. Otherwise it will impair prescribed per-

formance and cause burning of the equipment itself.

■WIRING

• For wiring connection, refer to “TERMINAL CONNEC-

TIONS” and wire correctly. Fire, electric shock and fail-

ure cause if wire are incorrectly connected.

• Wire using vinyl insulated power cable that meet input

voltage and load current for equipment and screw by an

adequate torque.

Loose screws may abnormally generate heat and fire may

cause. (Proper tightening torque [N·m] : 0.98 – 1.18)

• Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.