ASWL2

P. 1 / 3EM-1619 Rev.2

BEFORE USE ....

Thank you for choosing M-System. Before use,check the package

you received as below.

If you have any problems or questions with the product, please

contact M-System's Sales Office or representatives.

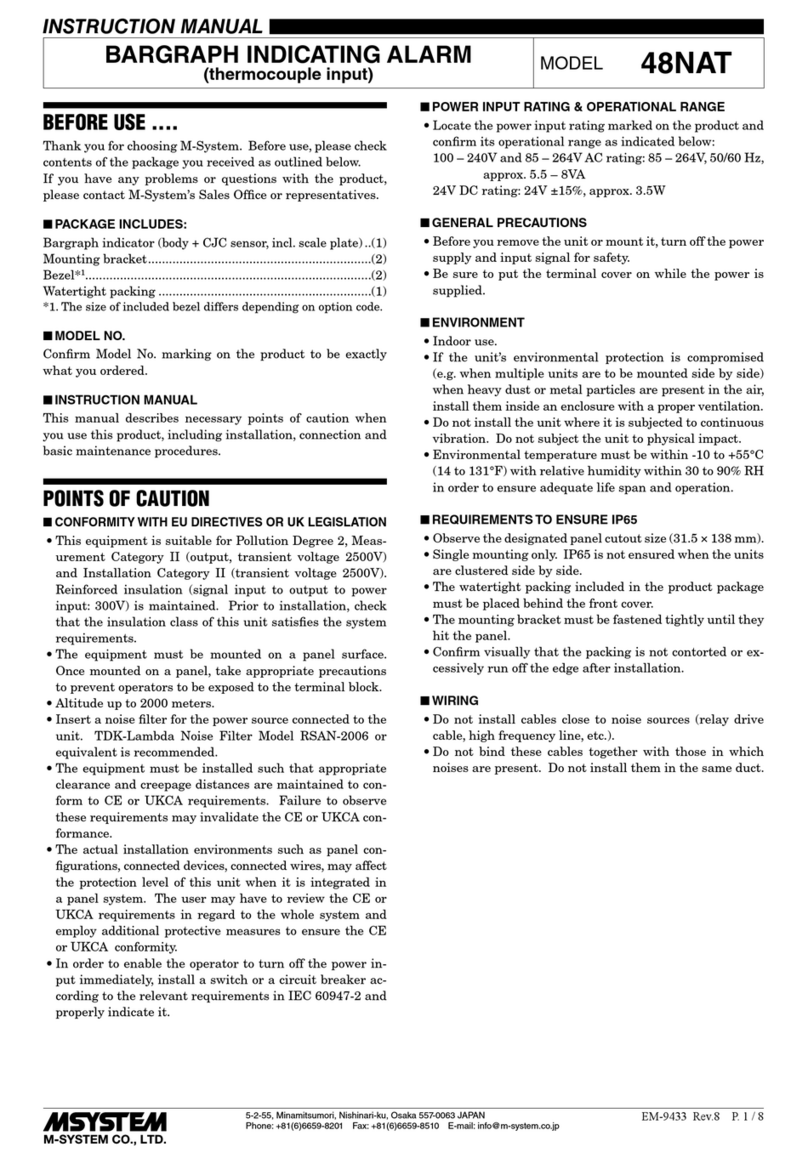

n PACKAGE INCLUDES:

Signal conditioner (body + base socket + input resistor).....(1)

Input resistor is provided only with current input type.

n MODEL NO.

Check that model No. described on specification label is exactly

what you ordered.

n INSTRUCTION MANUAL

This manual describes necessary points of caution when you

use this product, installation, connection and basic maintenance

procedures.

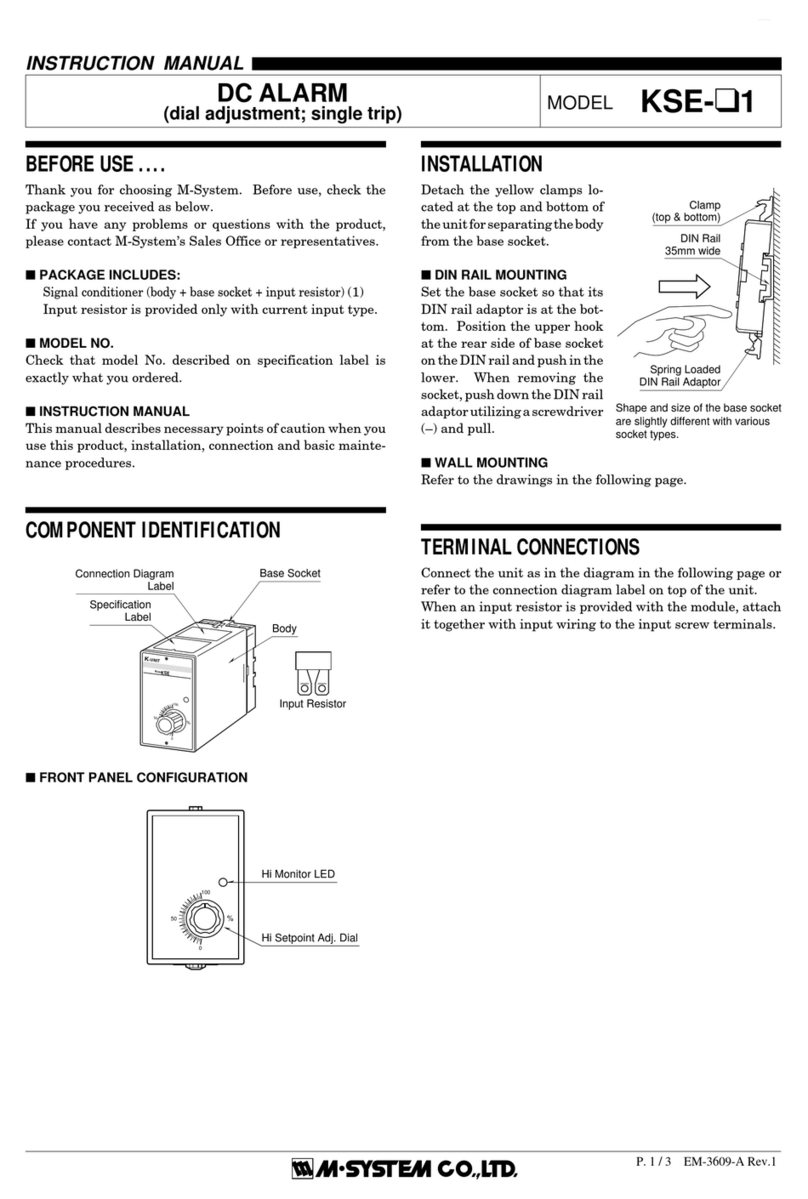

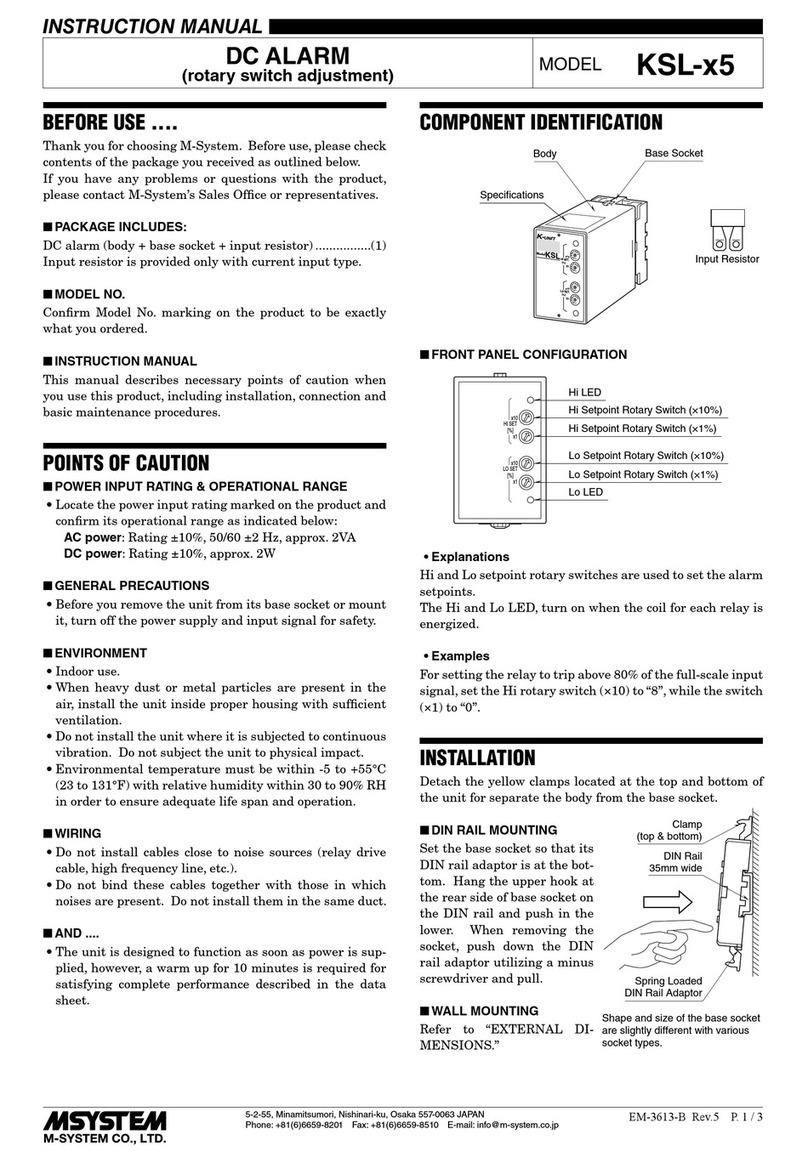

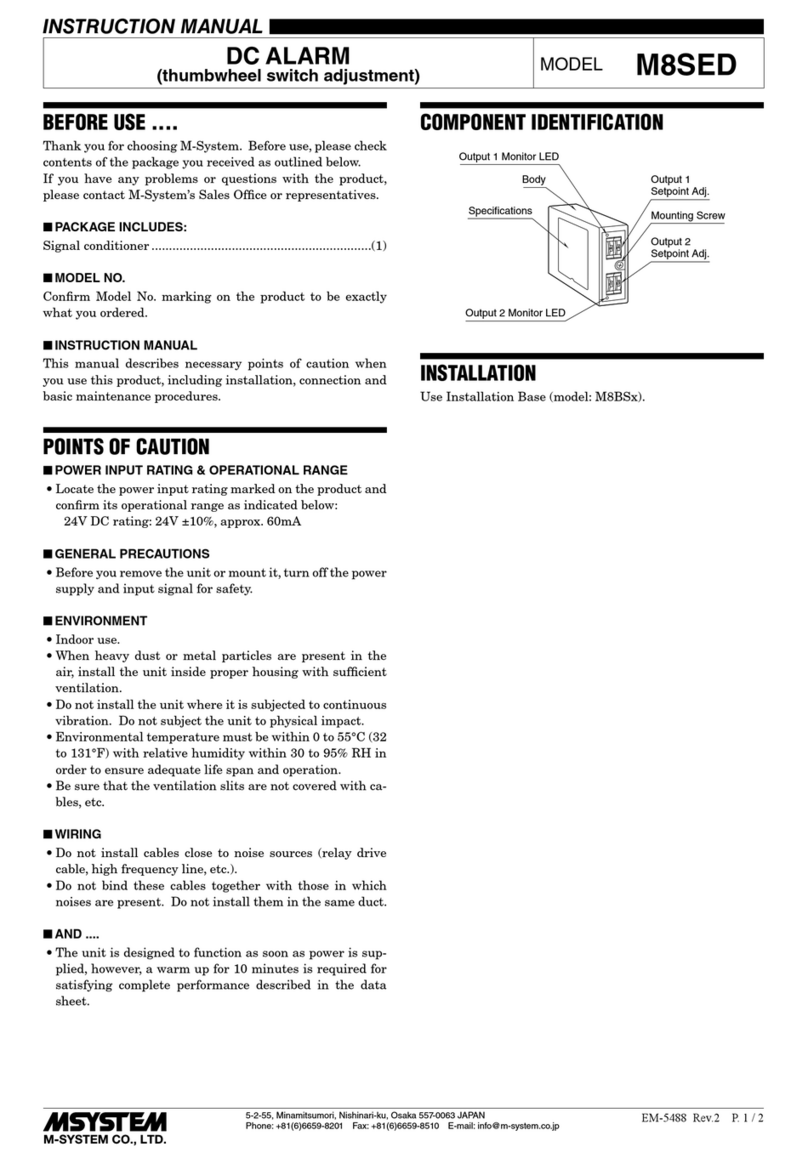

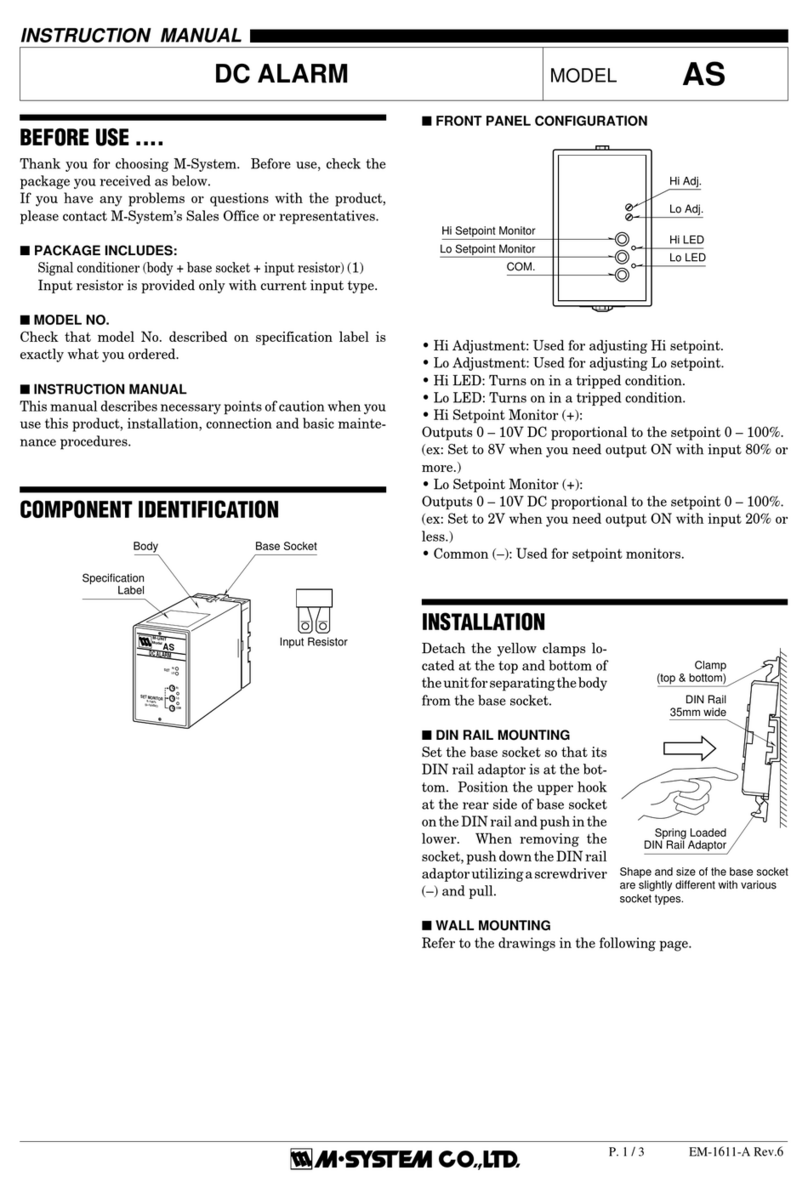

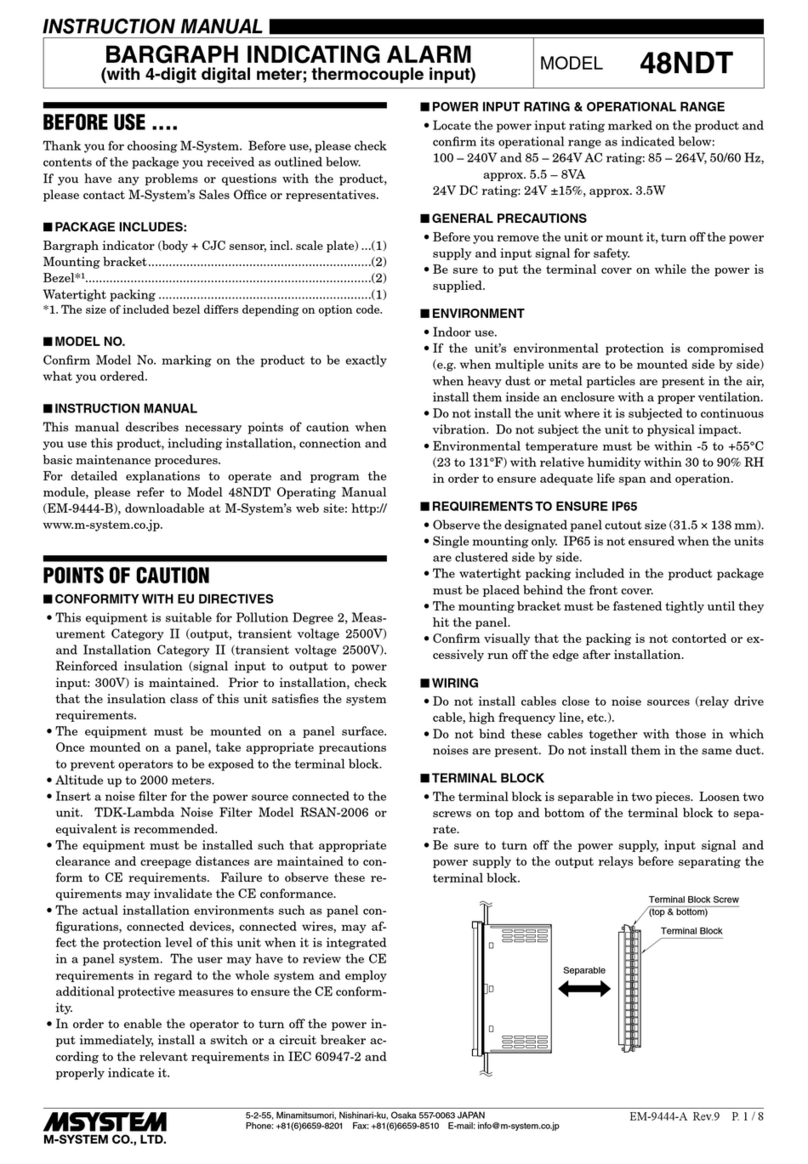

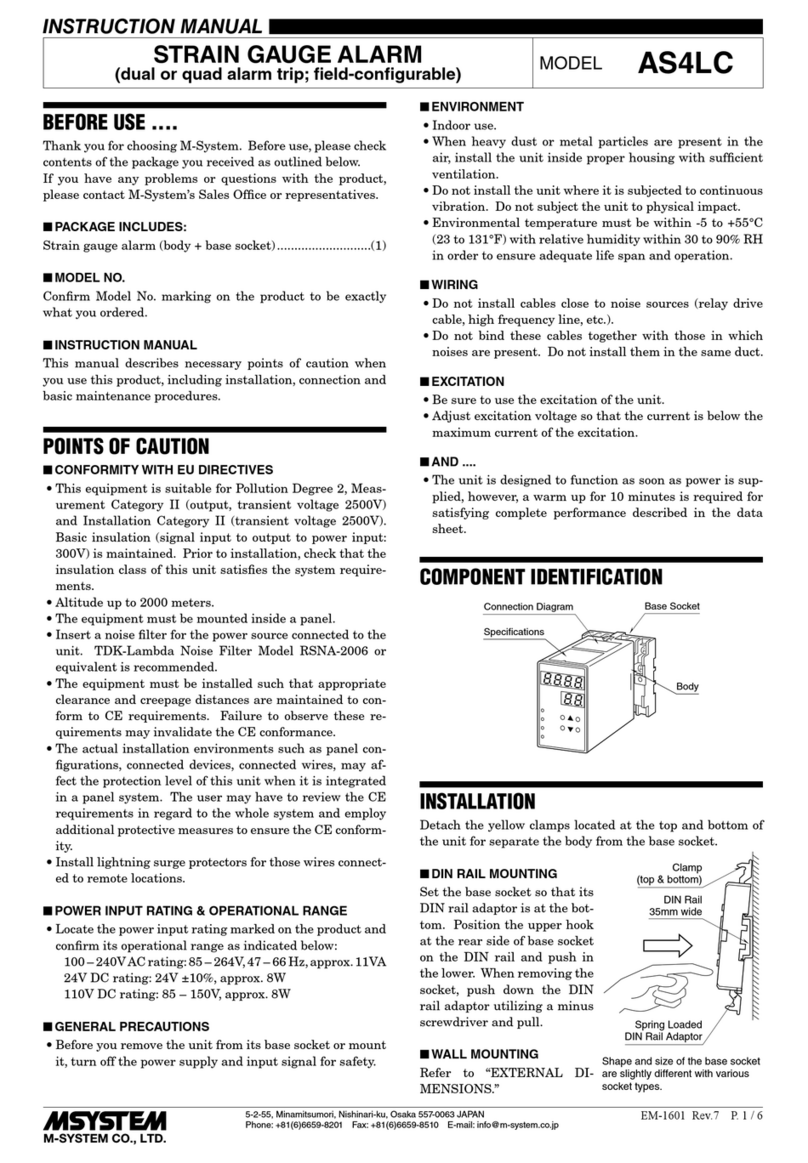

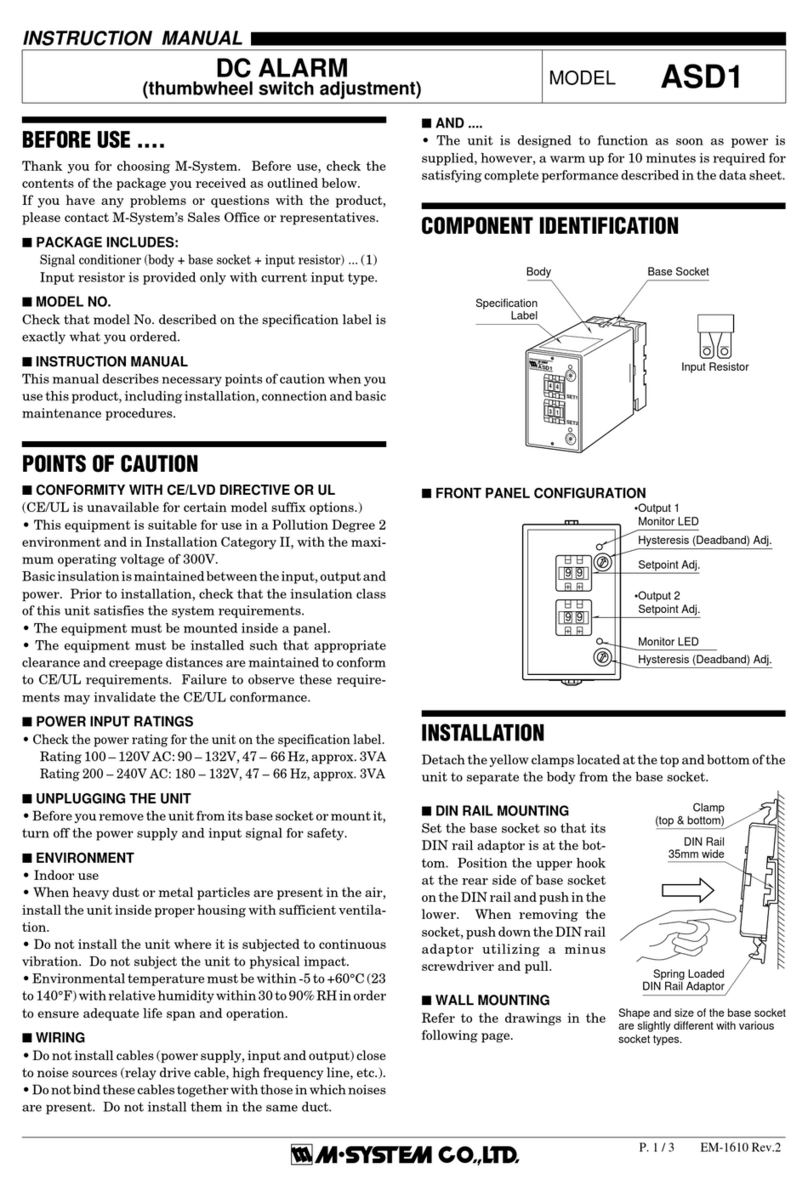

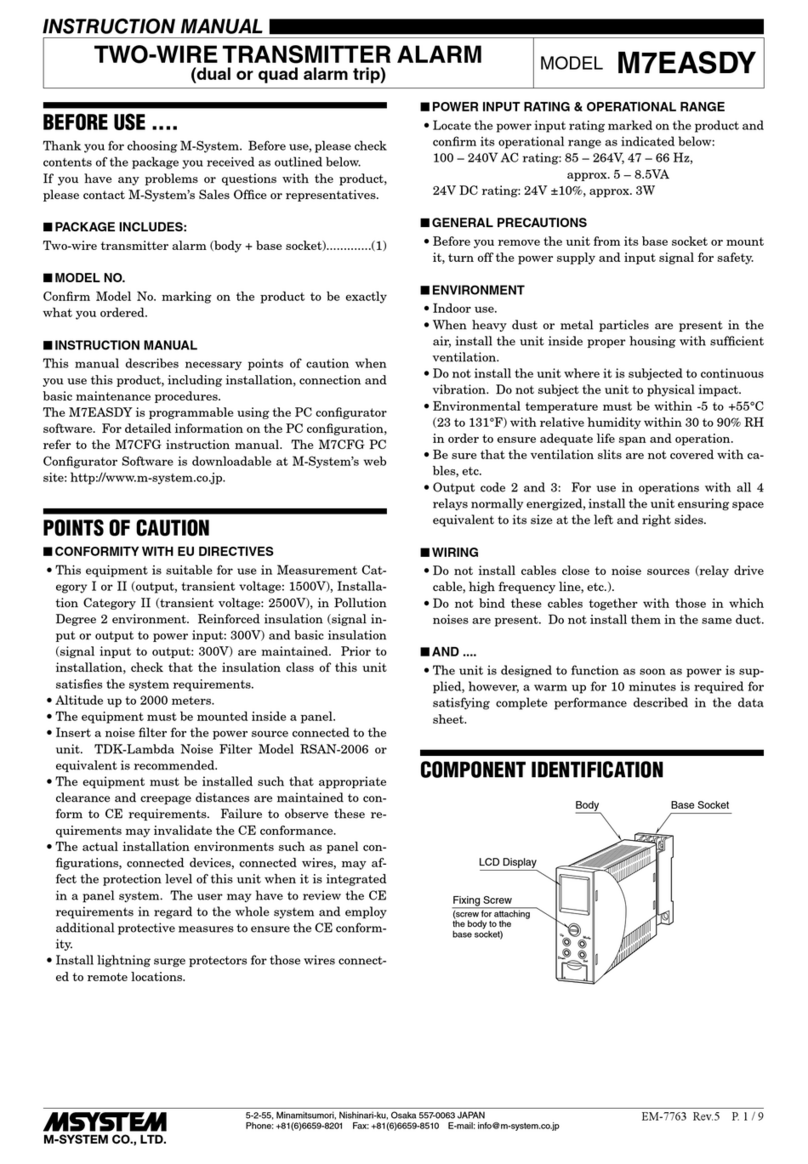

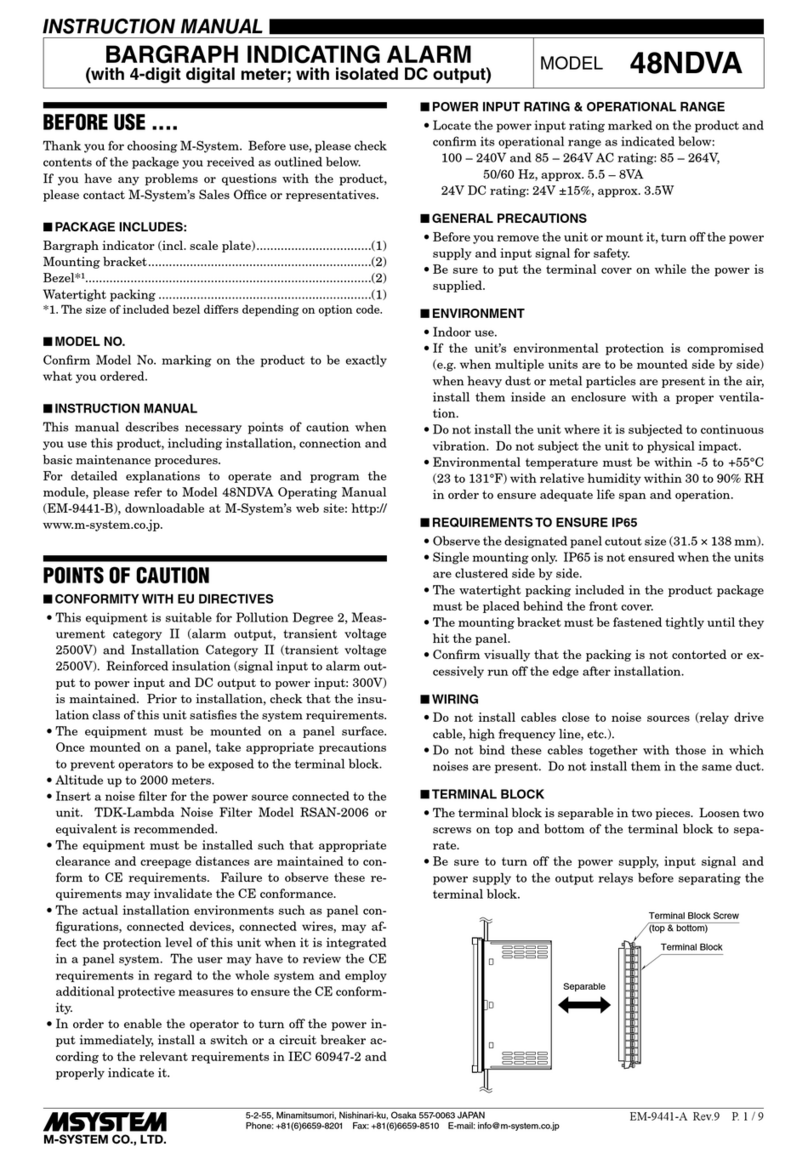

COMPONENT IDENTIFICATION

Body Base Socket

Specification

Label

x10

HI SET.

(%)

X1

x10

LO SET.

(%)

X1

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

DC ALARM

(rotary switch adjustment) MODEL ASWL2

INSTRUCTION MANUAL

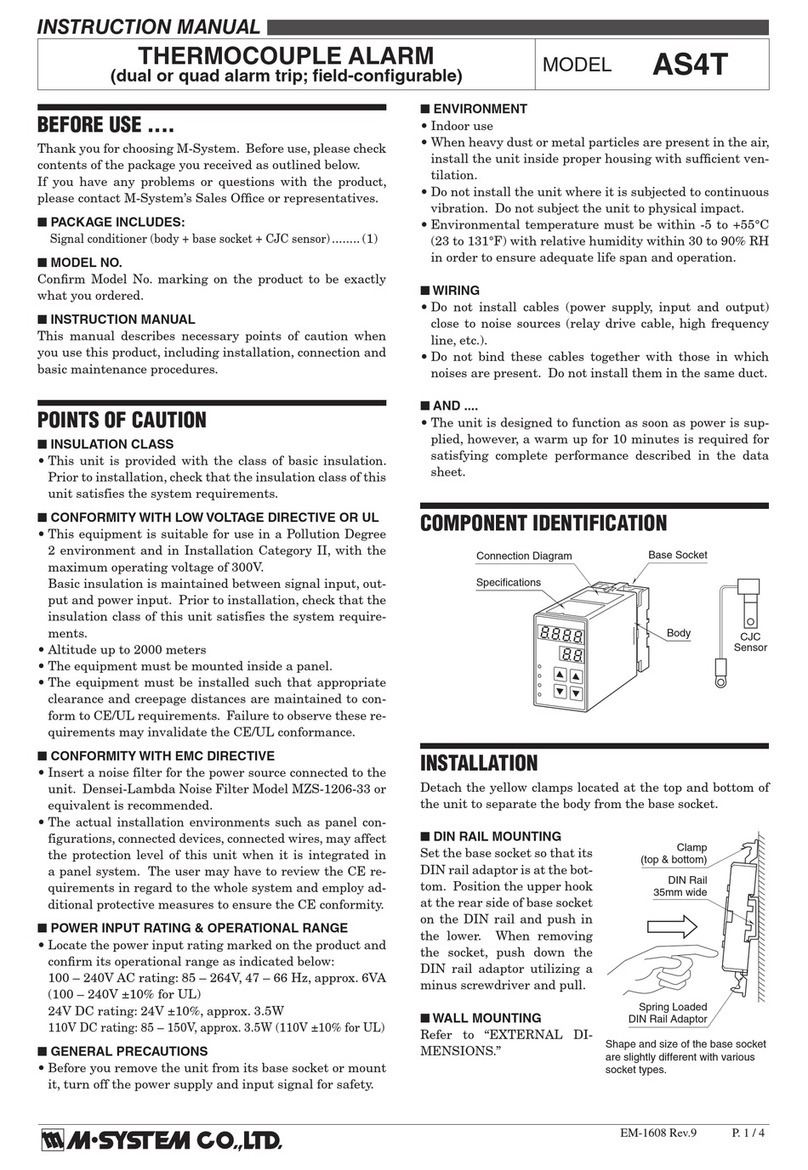

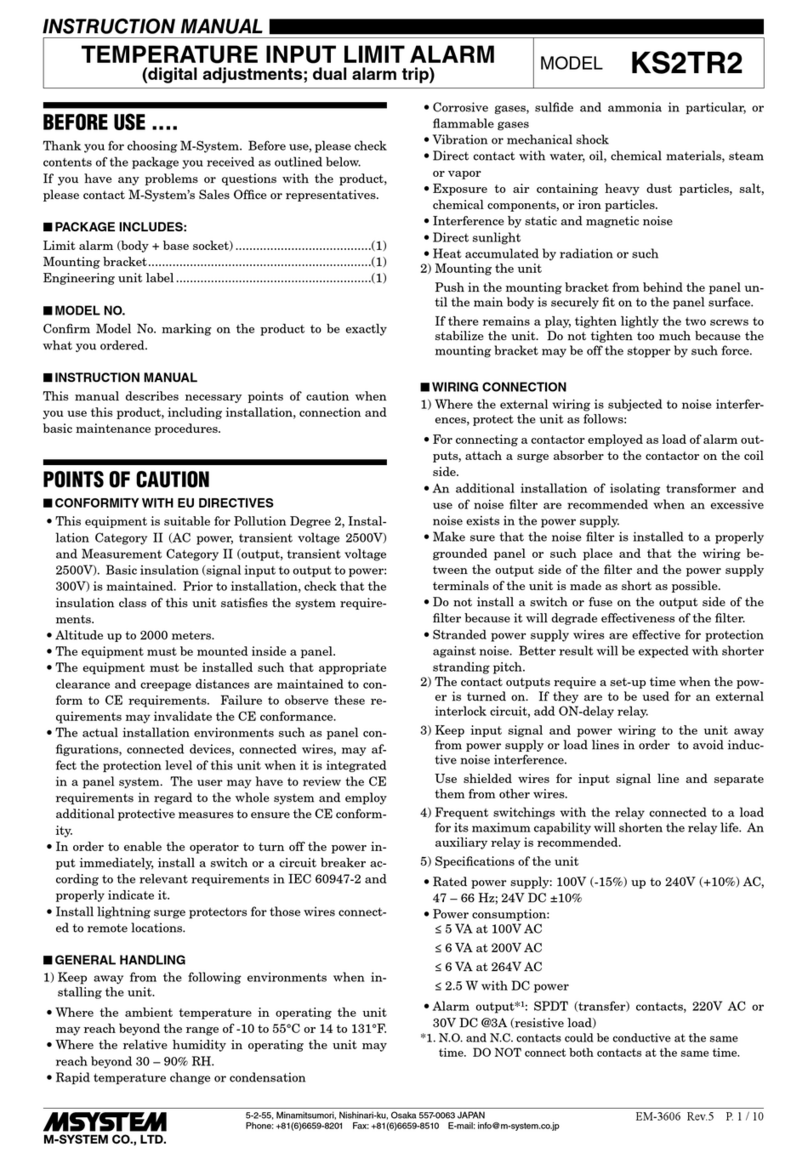

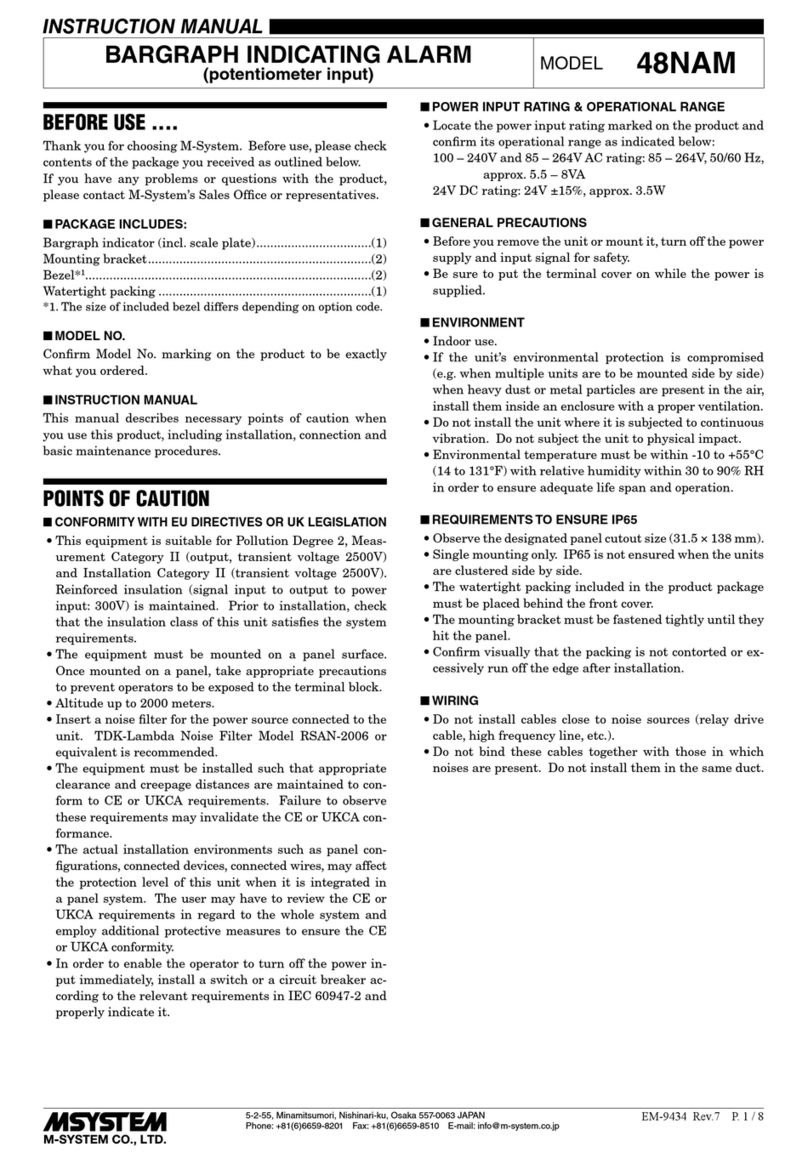

INSTALLATION

Detach the yellow clamps located at the top and bottom of the

unit for separating the body from the base socket.

n DIN RAIL MOUNTING

Set the base socket so that its

DIN rail adaptor is at the bot-

tom. Position the upper hook at

the rear side of

base socket on the DIN rail and

push in the lower. When remov-

ing the socket, push down the

DIN rail

adaptor utilizing a screwdriver

(–) and pull.

n WALL MOUNTING

Refer to “EXTERNAL DIMEN-

SIONS.”

Clamp

(top & bottom)

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

Shape and size of the base socket

are slightly different with various

socket types.

POINTS OF CAUTION

nCONFORMITY WITH EC DIRECTIVES

• This equipment is suitable for Pollution Degree 2 and Instal-

lation Category II.

The relay output circuit is suitable for use in Pollution Degree

2 environment in Over Voltage Category II with the maximum

operating voltage 150V, in Over Voltage Category I with 240V.

Reinforced insulation (signal input or output to power input:

300V) and basic insulation (signal input to output: 300V) are

maintained. Prior to installation, check that the insulation

class of this unit satisfies the system requirements.

• The equipment must be mounted inside a suitable re enclosure.

• Altitude up to 2000 meters

• The equipment must be installed such that appropriate clear-

ance and creepage distances are maintained to conform to CE

requirements. Failure to observe these requirements may

invalidate the CE conformance.

nPOWER INPUT RATINGS

• Operational range & power consumption: Check the power

rating for the unit on the specification label.

AC rating: Rating ±10%, 50/60 ±2 Hz, approx. 2VA

DC rating: Rating ±10%, approx. 2W

n GENERAL

• Before you remove the unit from its base socket or mount it,

turn off the power supply and input signal for safety.

n ENVIRONMENT

• Indoor use.

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing and ventilate it.

• Do not install the unit where it is subjected to continuous

vibration. Do not apply physical impact to the unit.

• Environmental temperature must be within -5 to +60°C (23

to 140°F) with relative humidity within 30 – 90% RH in order

to ensure adequate life span and operation.

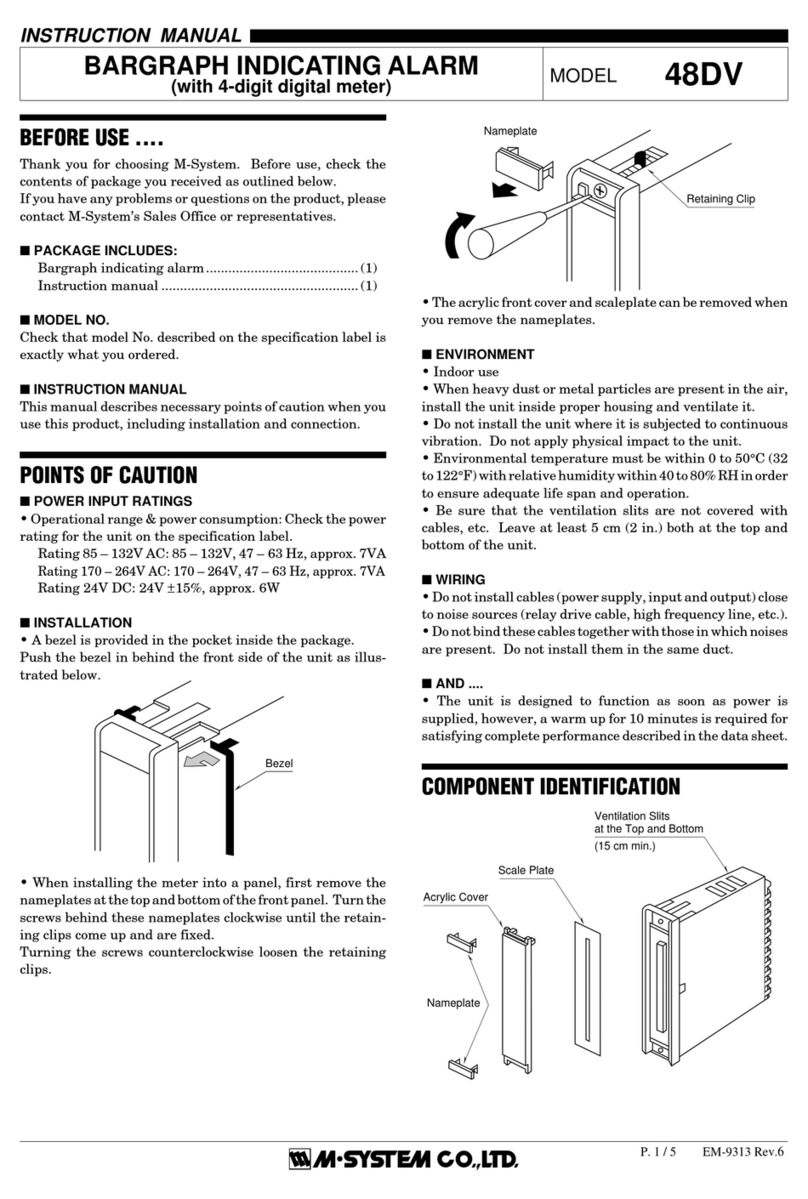

Input Resistor

n WIRING

• Do not install cables (power supply, input and output) close

to noise sources (relay drive cable, high frequency line, etc.).

• Do not bind these cables together with those in which noises

are present. Do not install them in the same duct.

n AND ....

• The unit is designed to function as soon as power is supplied,

however, a warm up for 10 minutes is required for satisfying

complete performance described in the data sheet.