AS4V

P. 1 / 4 EM-1609 Rev.9

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System's Sales Office or representatives.

■ PACKAGE INCLUDES:

Signal conditioner (body + base socket + input resistor) ...

(1)

Input resistor is provided only with current input type.

■ MODEL NO.

Check that model No. described on specification label is

exactly what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when you

use this product, including installation, connection and basic

maintenance procedures.

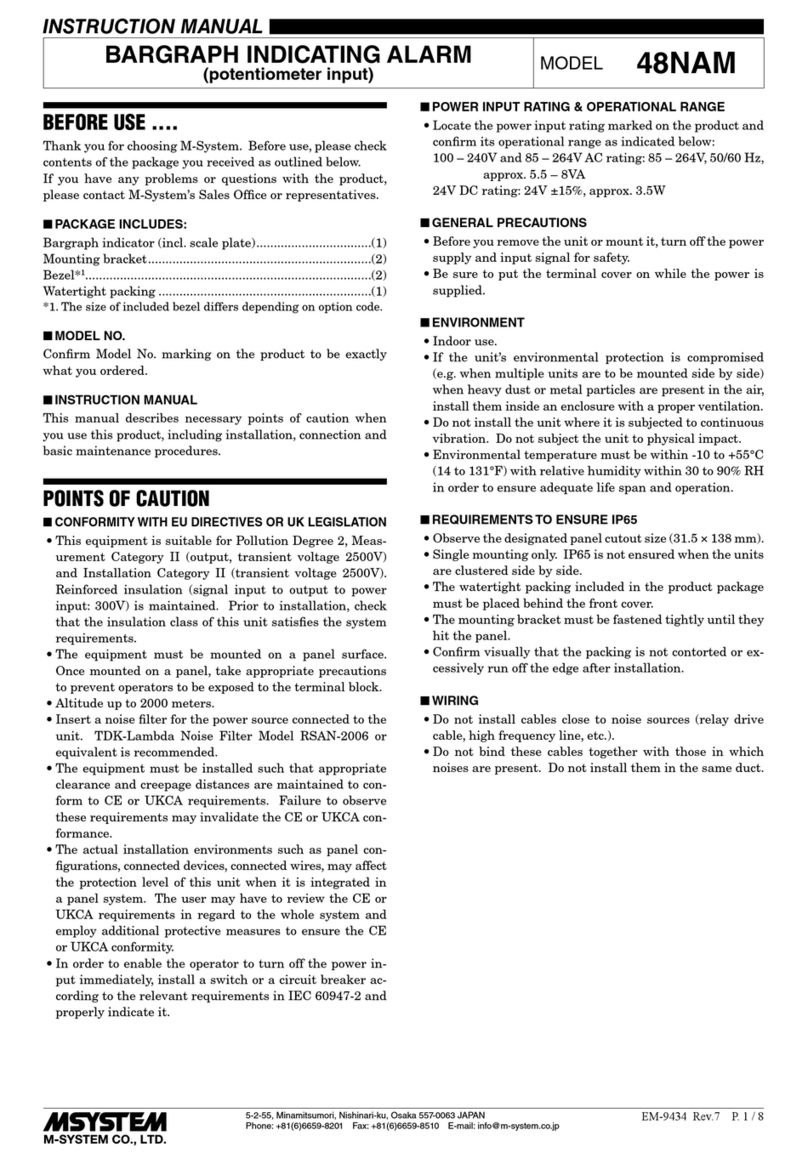

POINTS OF CAUTION

■ INSULATION CLASS

• This unit is provided with the class of basic insulation.

Prior to installation, check that the insulation class of this

unit satisfies the system requirements.

■ CONFORMITY WITH CE DIRECTIVES OR UL

•This equipment is suitable for use in a Pollution Degree 2

environment and in Installation Category II, with the maxi-

mum operating voltage of 300V.

Basic insulation is maintained between signal input, output

and power input. Prior to installation, check that the insula-

tion class of this unit satisfies the system requirements.

• Altitude up to 2000 meters

• The equipment must be mounted inside a panel.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to conform

to CE/UL requirements. Failure to observe these require-

ments may invalidate the CE/UL conformance.

• For the CE Conformity: Insert a noise filter for the power

source connected to the unit. Densei-Lambda Noise Filter

Model MZS-1206-33 or equivalent is recommended.

The actual installation environments such as panel configu-

rations, connected devices, connected wires, may affect the

protection level of this unit when it is integrated in a panel

system. The user may have to review the CE requirements

in regard to the whole system and employ additional protec-

tive measures to ensure the CE conformity.

■ POWER INPUT RATING & OPERATIONAL RANGE

• Operational range & power consumption: Check the power

rating for the unit on the specification label.

Rating 100 – 240V AC: 85 – 264V, 47 – 66 Hz, approx. 6VA

(100 – 240V ±10% for UL)

Rating 24V DC: 24V ±10%, approx. 3.5W

Rating110VDC:85–150V,approx.3.5W(110V ±10%forUL)

• Power fuse: A power fuse of the rating as shown below is

incorporated for safety. However, DO NOT replace it by the

user.

T 0.25A 250V

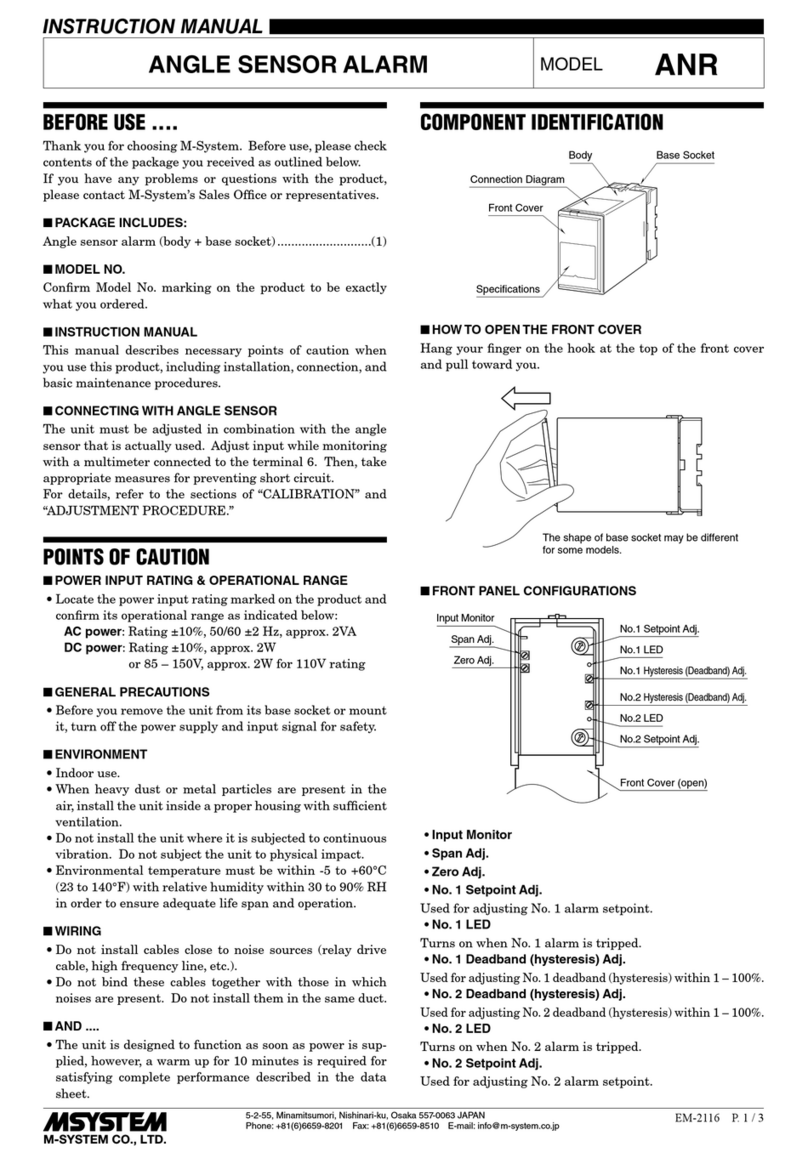

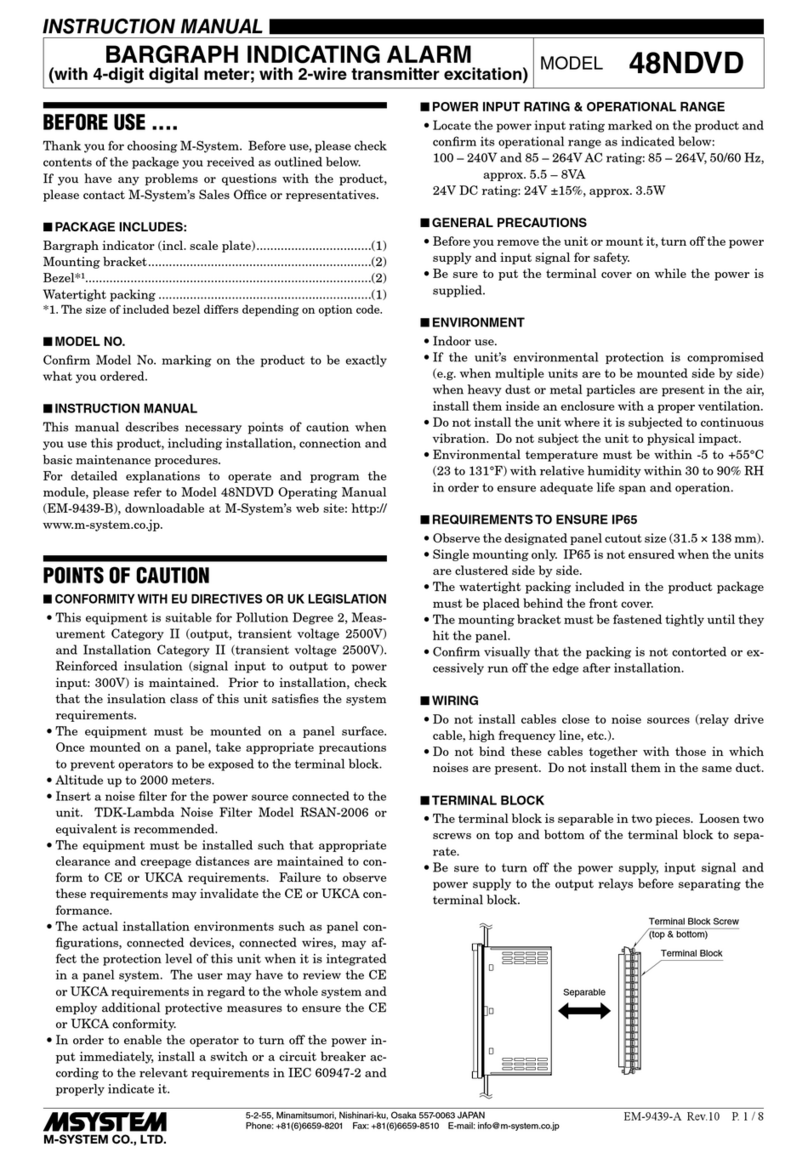

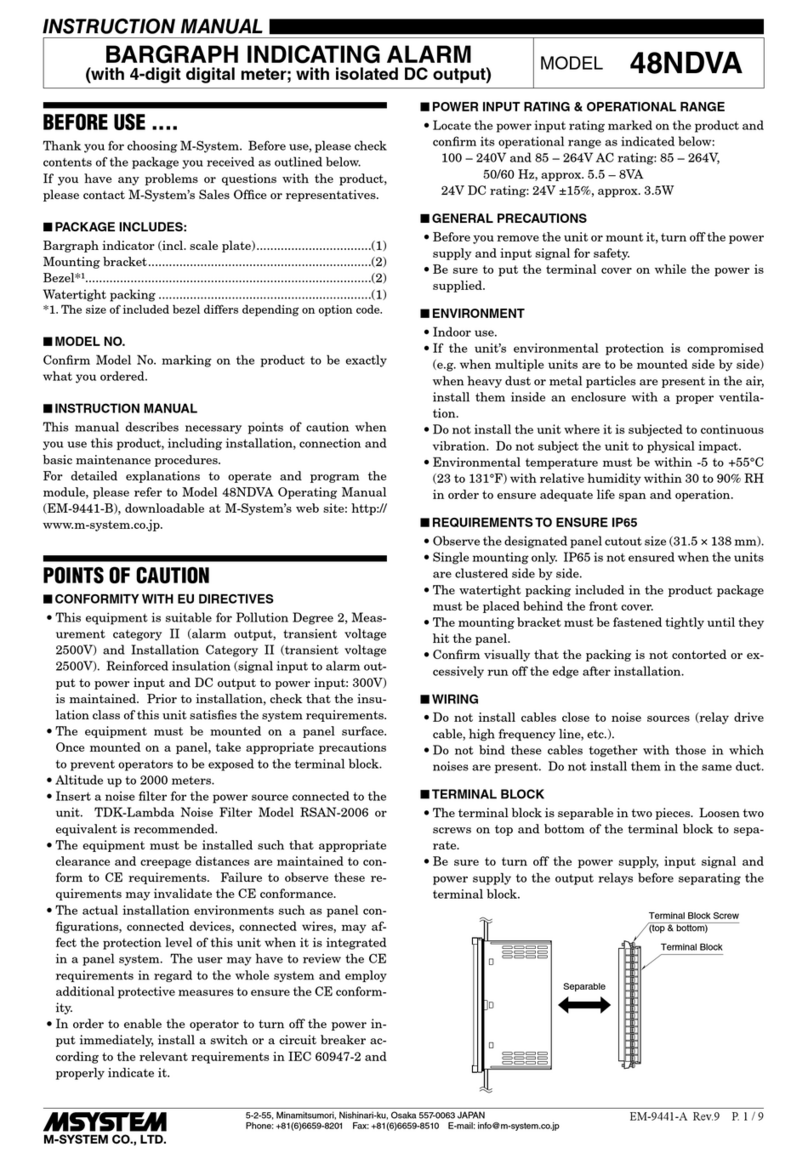

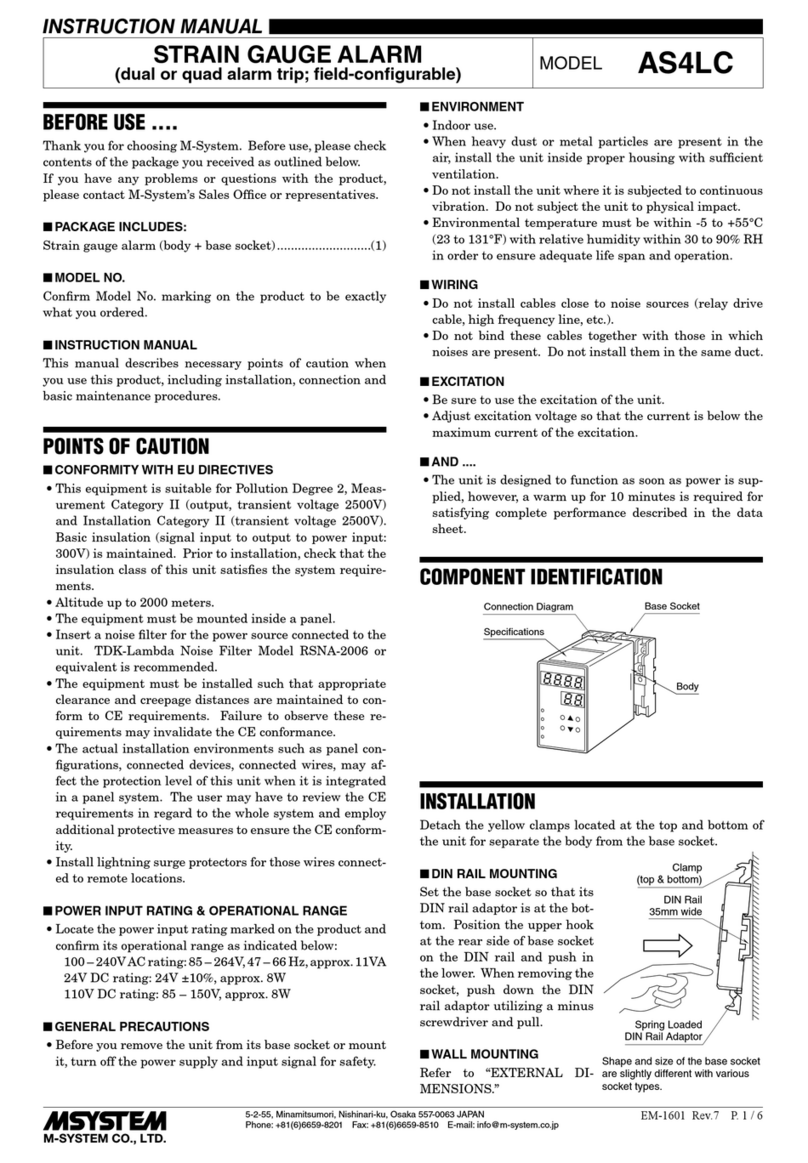

INSTRUCTION MANUAL

MODEL AS4V

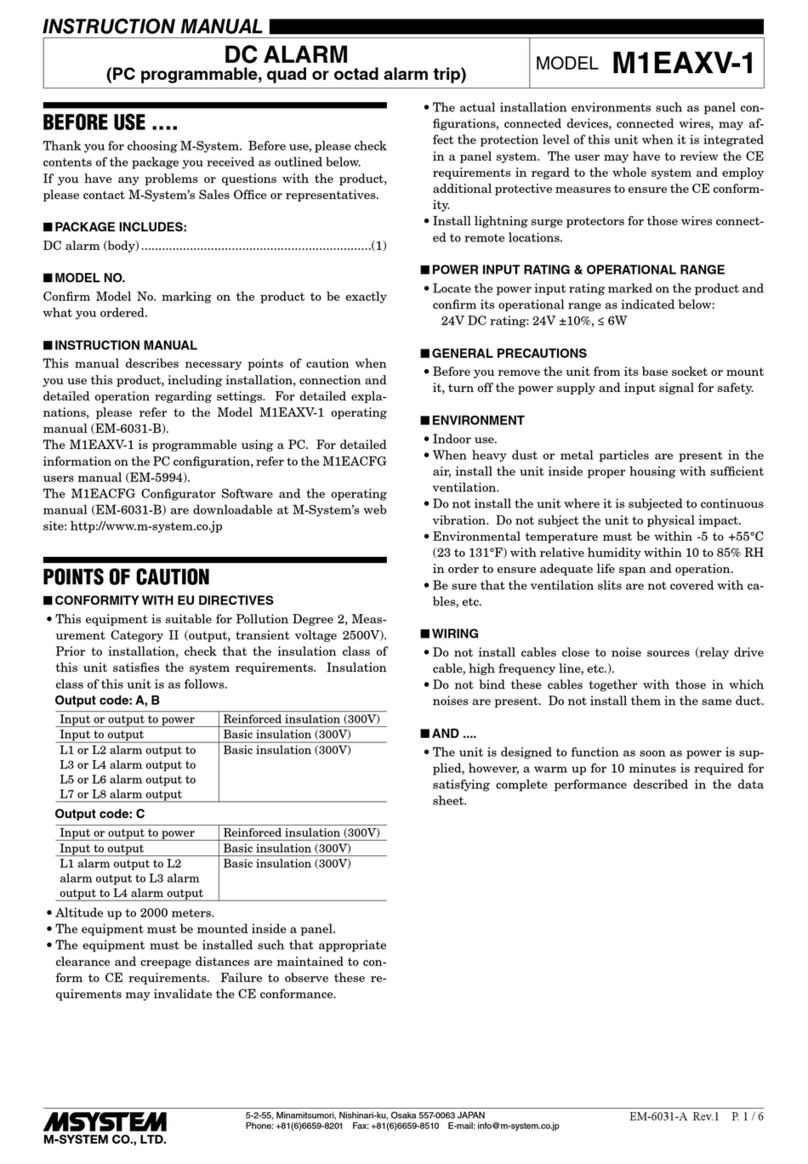

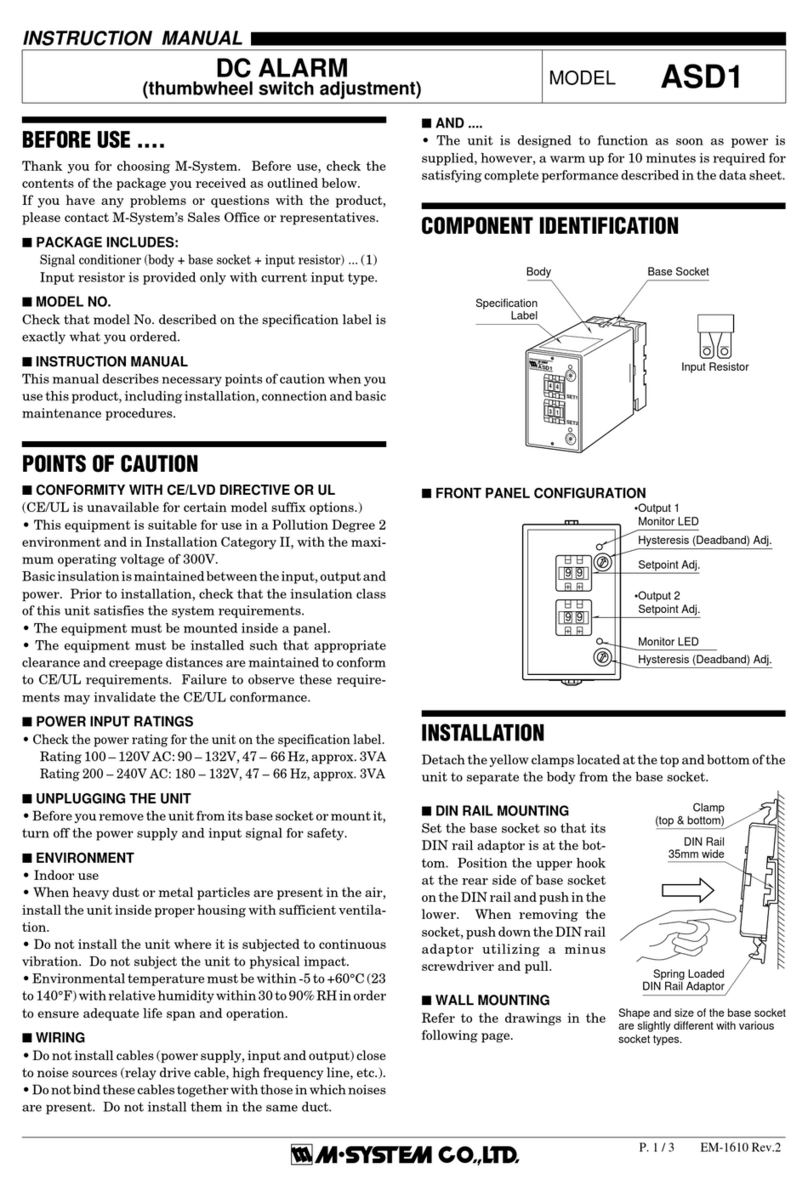

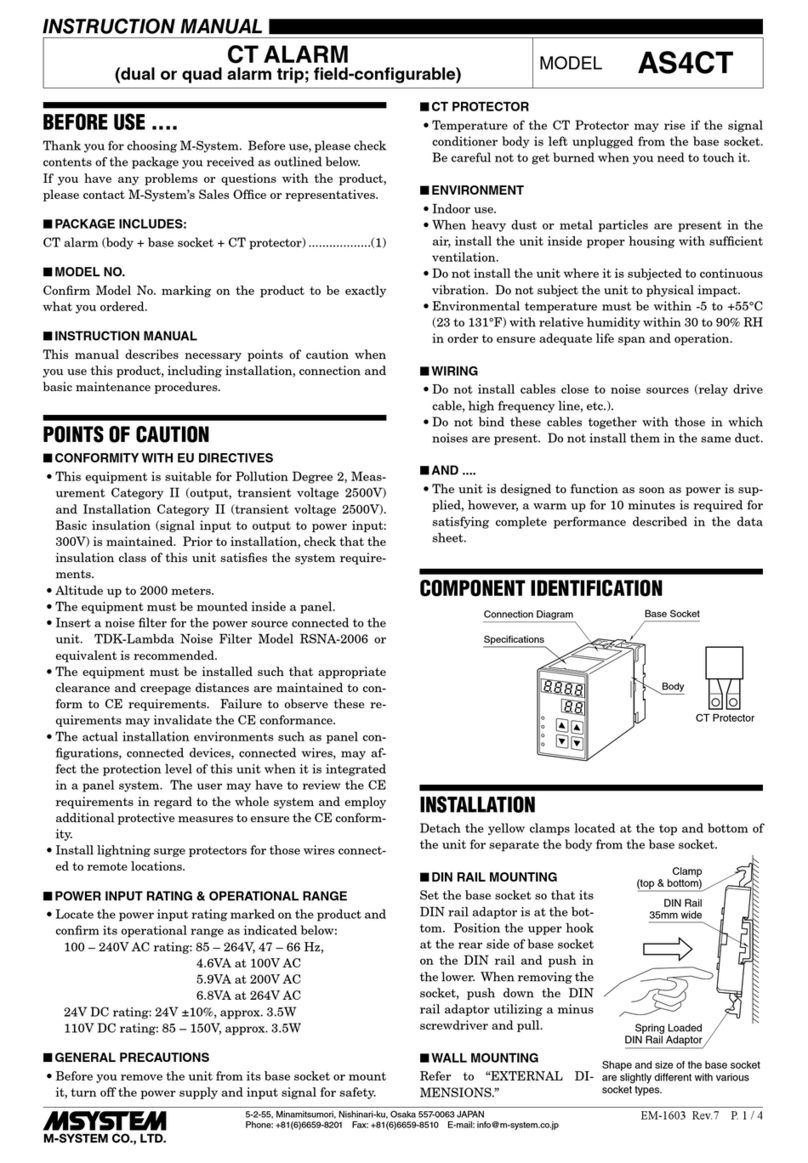

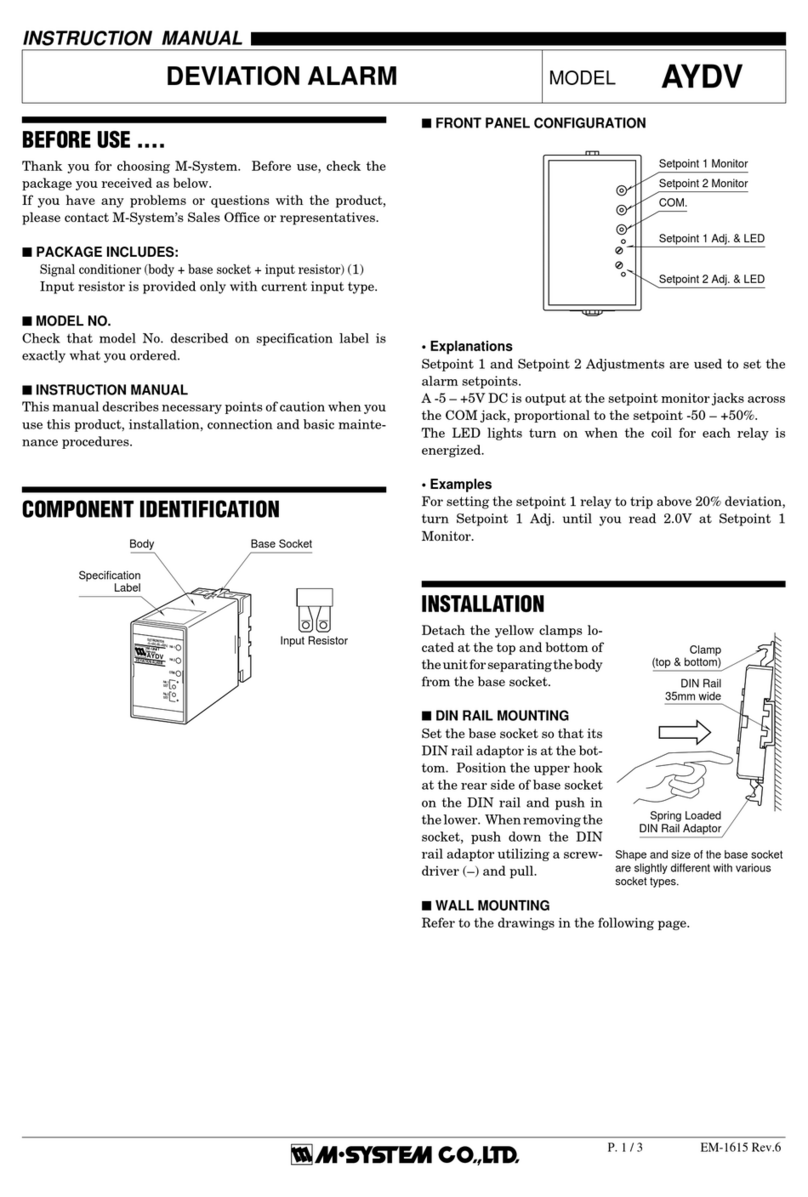

Input Resistor

DC ALARM

(dual or quad alarm trip; field-configurable)

Connection

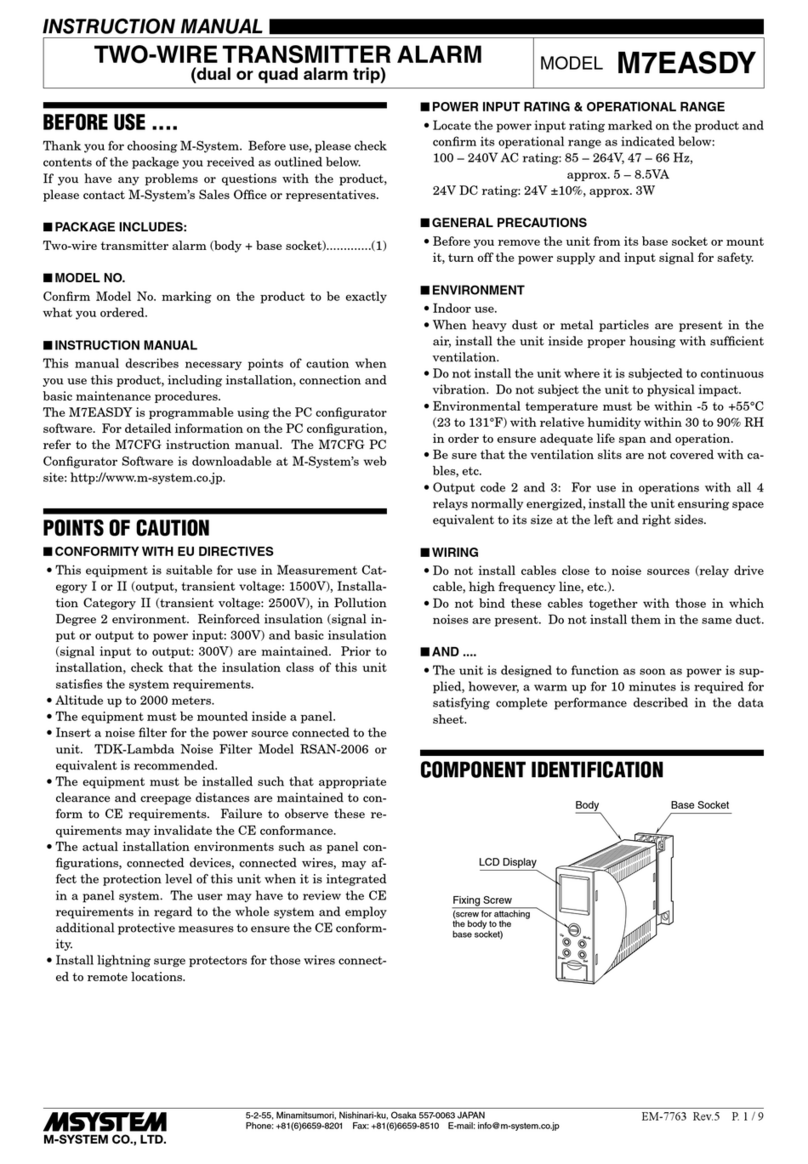

Diagram Label Base Socket

Body

Specification

Label

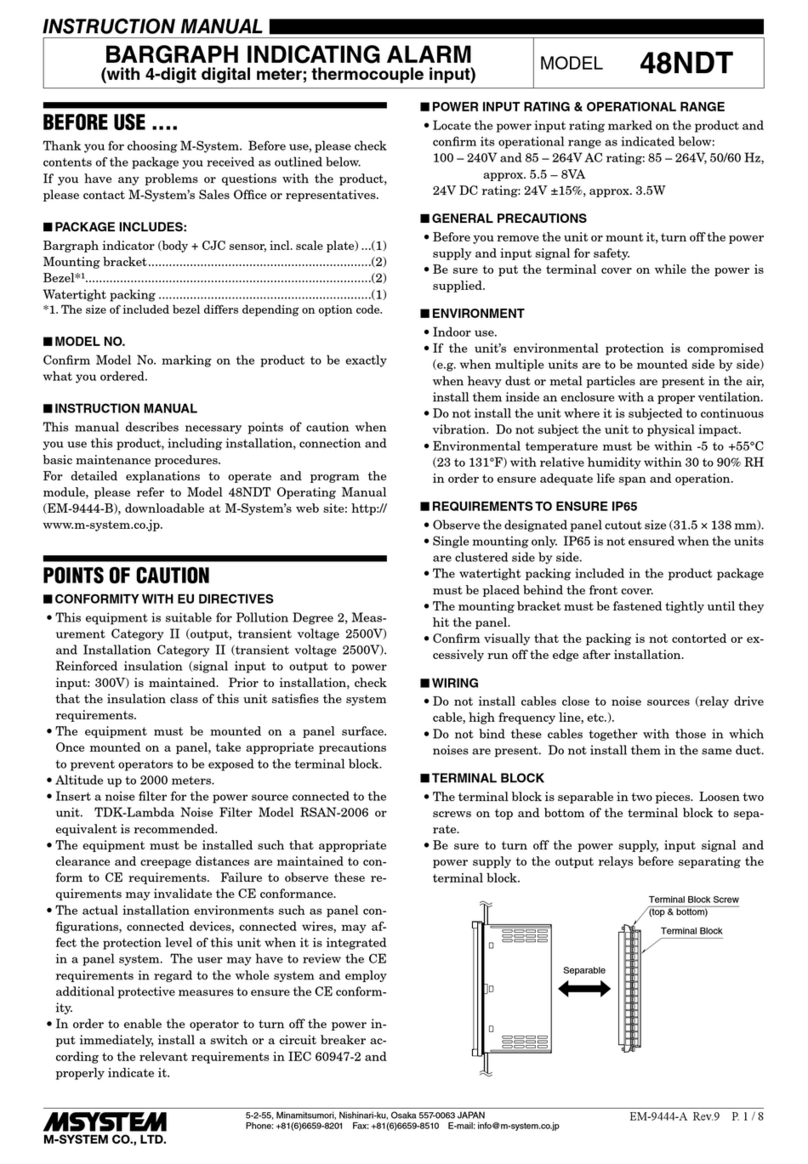

Clamp

(top & bottom)

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

Shape and size of the base socket

are slightly different with various

socket types.

■ UNPLUGGING THE UNIT

• Before you remove the unit from its base socket or mount it,

turn off the power supply and signal input for safety.

■ ENVIRONMENT

• Indoor use

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing with sufficient ventila-

tion.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C (23

to131°F) with relative humidity within 30 to90% RH in order

to ensure adequate life span and operation.

■ WIRING

• Do not install cables (power supply, input and output) close

to noise sources (relay drive cable, high frequency line, etc.).

• Do not bind the unit's cables together with cables where

high noise levels are present. Do not install them in the same

duct.

■ AND ....

• The unit is designed to function as soon as power is

supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data sheet.

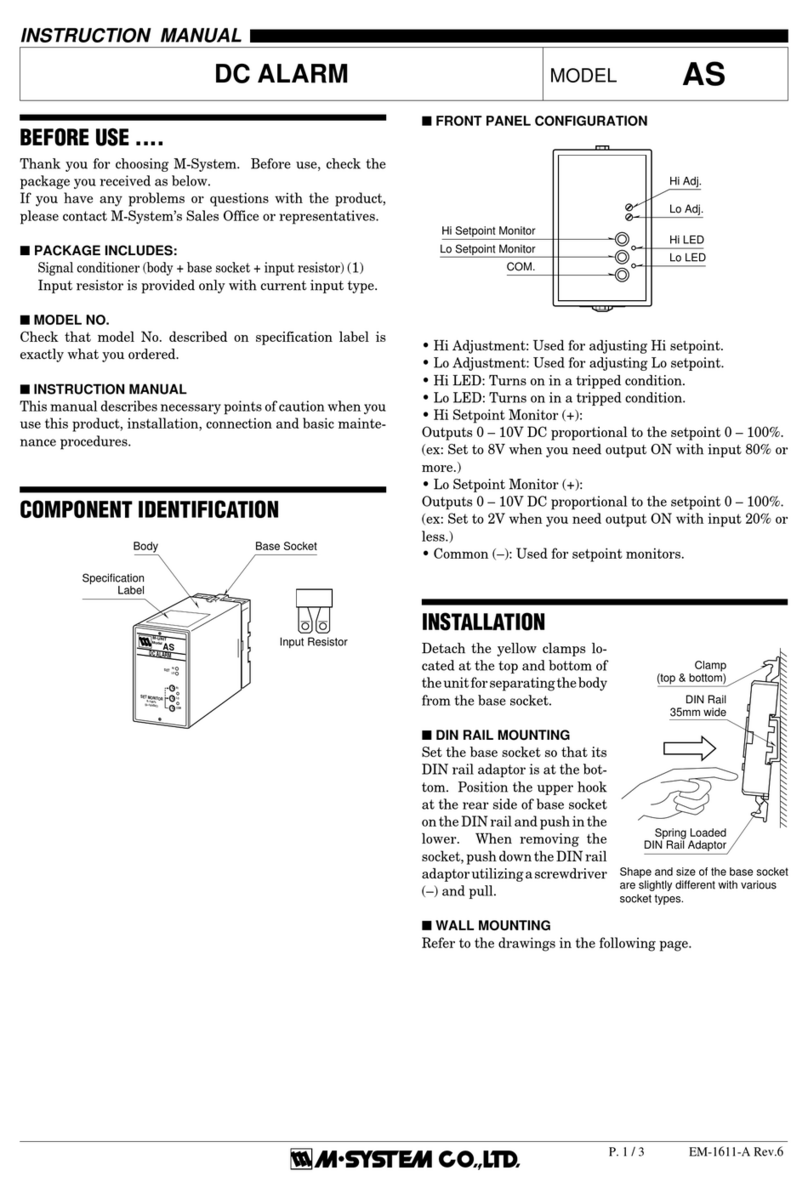

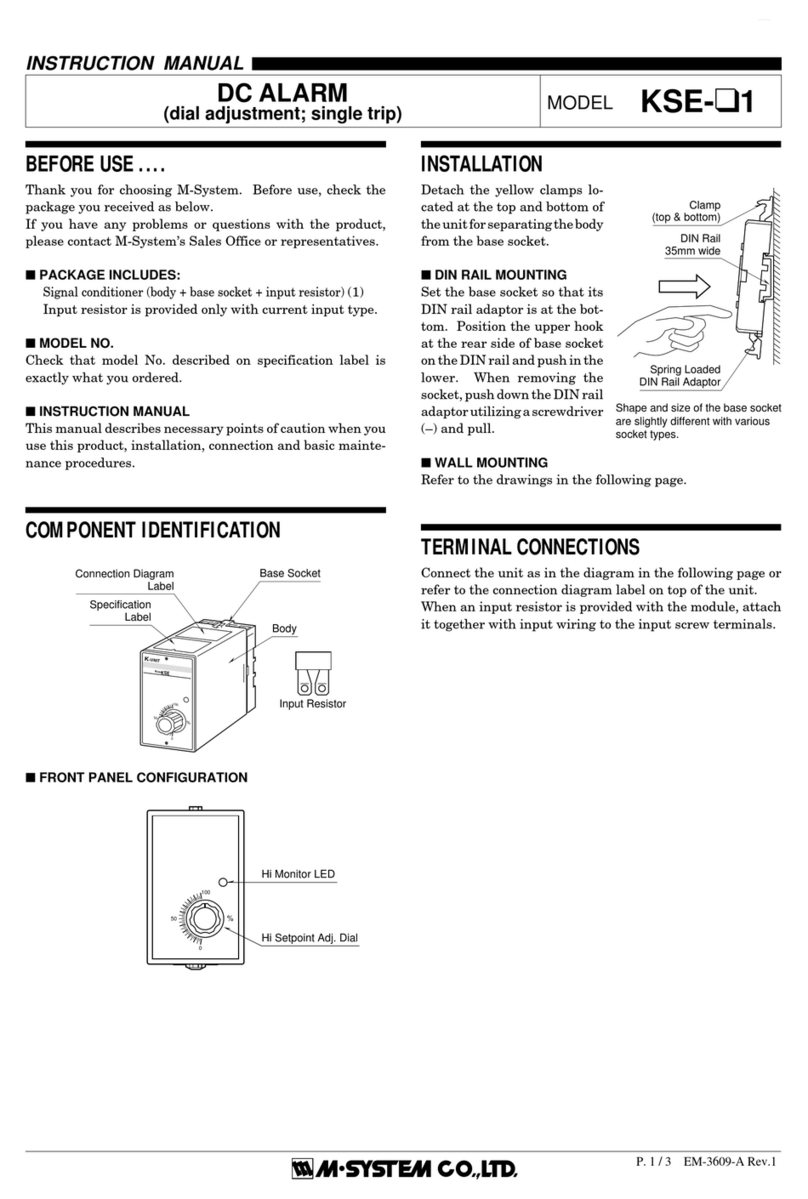

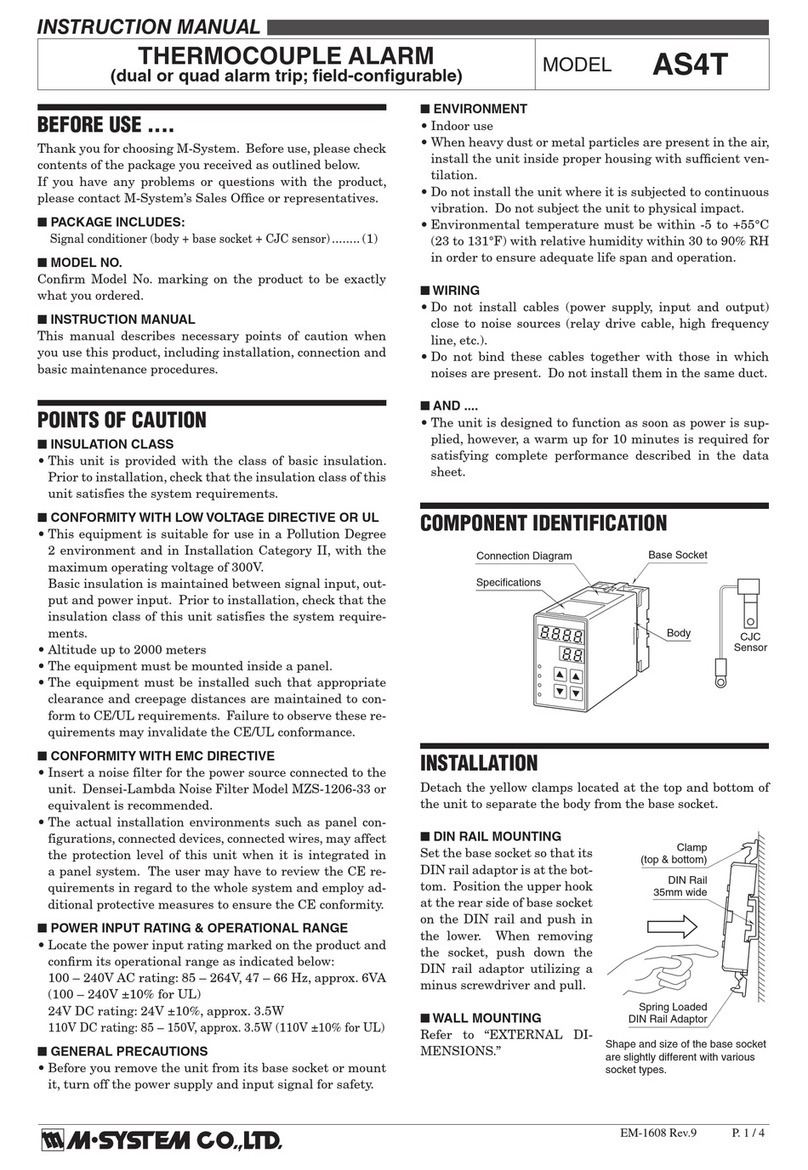

COMPONENT IDENTIFICATION

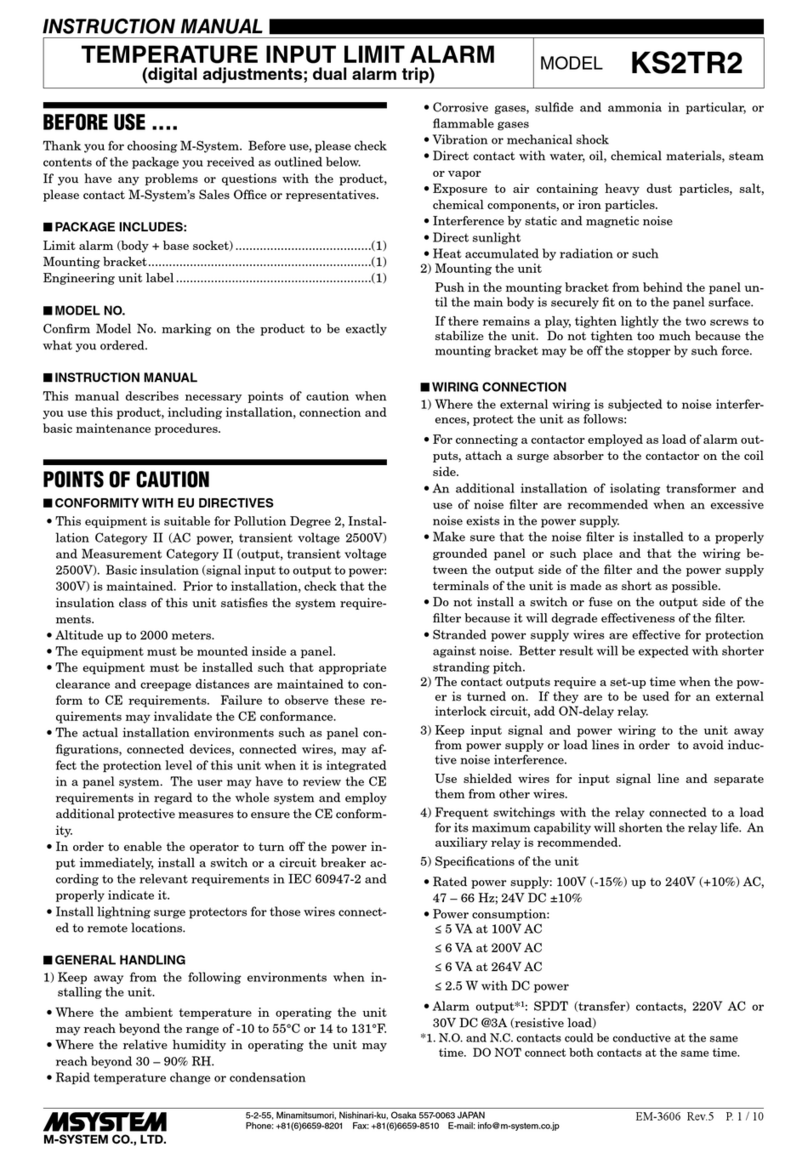

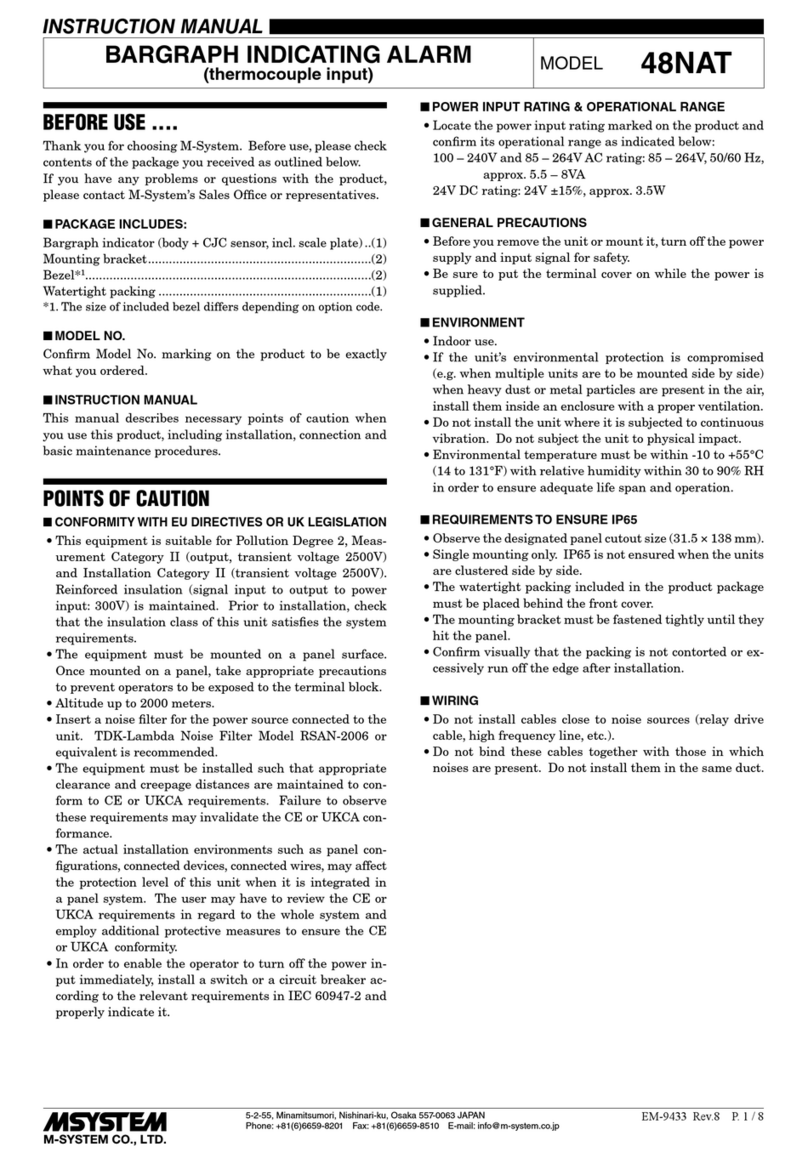

INSTALLATION

Detach the yellow clamps located at the top and bottom of the

unit for separating the body from the base socket.

■ DIN RAIL MOUNTING

Set the base socket so that its

DIN rail adaptor is at the bot-

tom. Position the upper hook

at the rear side of base socket

on the DIN rail and push in the

lower. When removing the

socket, push down the DIN rail

adaptor utilizing a minus

screwdriver and pull.

■ WALL MOUNTING

Refer to the drawings in the

“TERMINAL CONNECTION”

section.