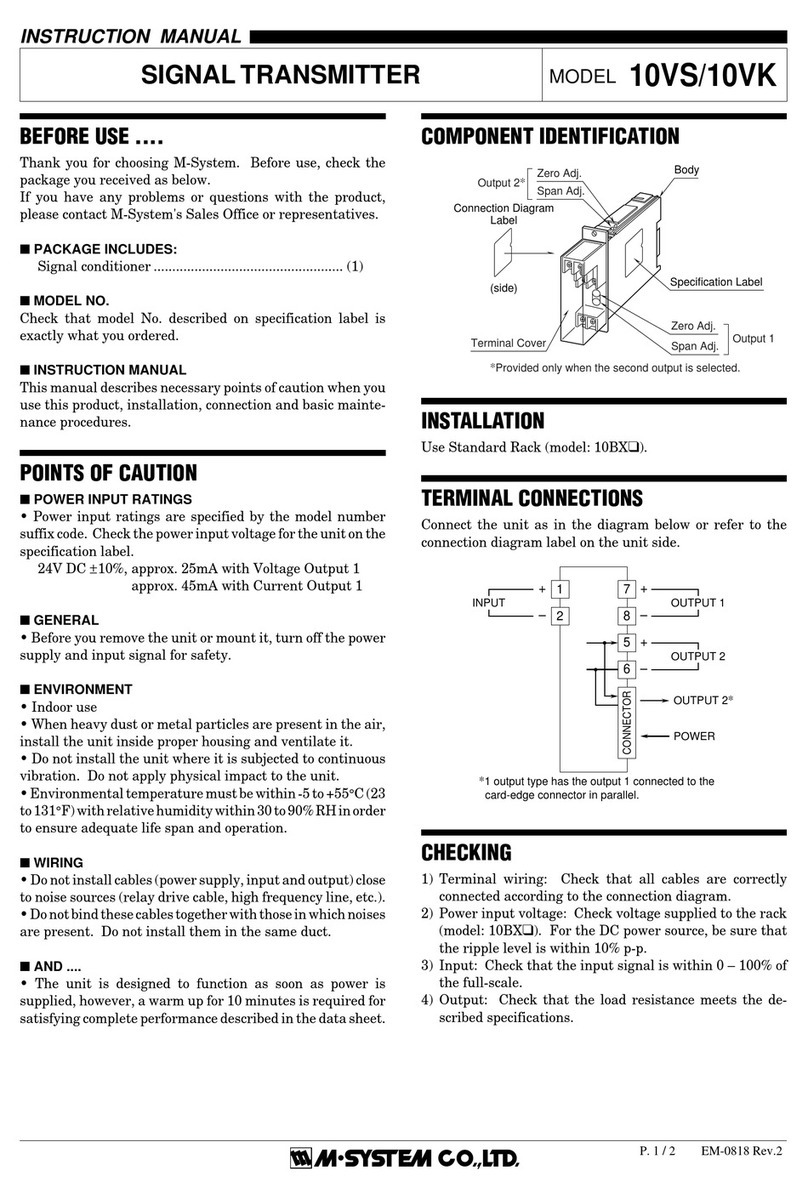

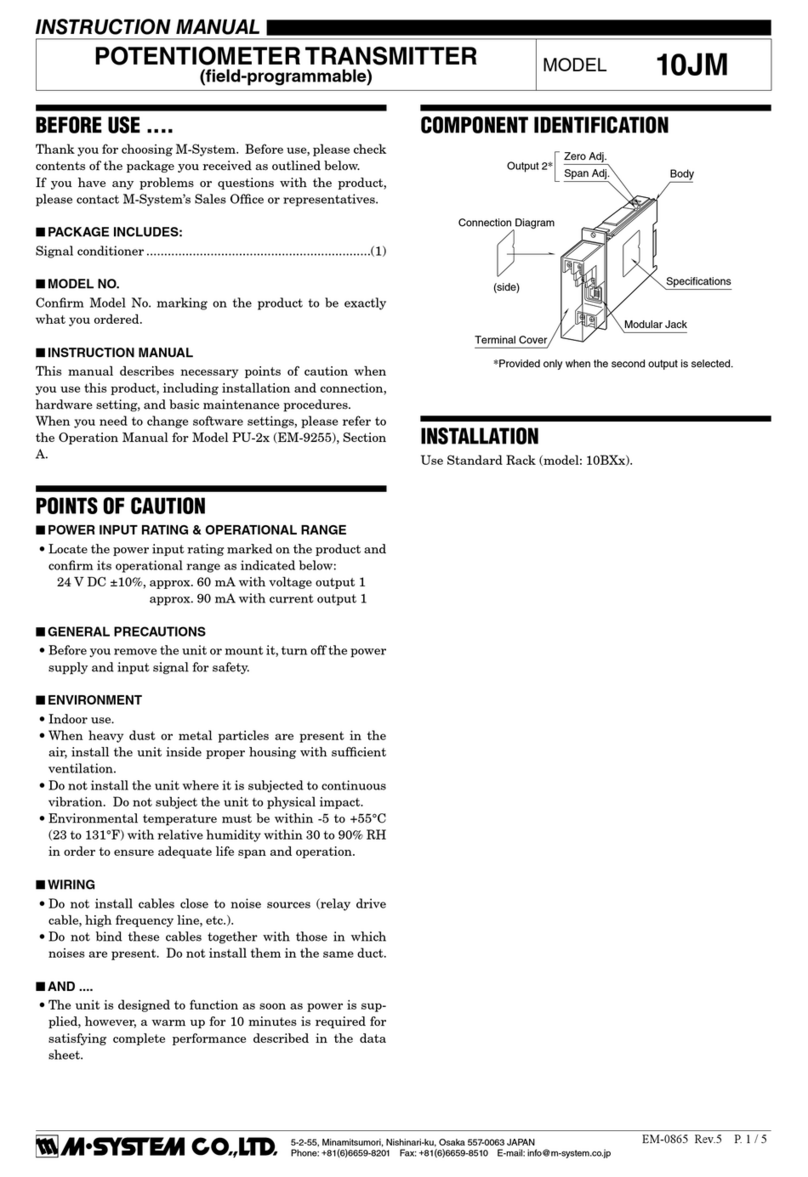

2) Make wiring as shown below. Turn power supply on, and

warm up for about 10 minutes.

FREQUENCY

GENERATOR

DIGITAL

VOLTMETER

6PA

POWER

24V DC

+15

234

6

–

+–

RL

RL: STANDARD LOAD (250Ω ±0.1%)

DIGITAL VOLTMETER: 4 DIGITS

• Requirements for Calibration Equipment

Frequency Generator: Accuracy ±0.04% or better re-

quired.

Digital Voltmeter: 4-digit meter.

Accuracy ±0.01% or better required.

All calibration instruments must meet or exceed the above

mentioned specifications. M-System does not guarantee

this product’s stated accuracies and specifications if these

calibration requirements are not met.

■INPUT FREQUENCY RANGE SETTING

Use SW1 for the frequency range setting.

SW1

FREQUENCY RANGE (Hz)*

36 ≤

< 100

100 ≤

< 240

240 ≤

< 480

480 ≤

< 1000

1 34 – 38 85 – 95 170 – 190 340 – 380

2 38 – 43 95 – 105 190 – 220 380 – 430

3 43 – 48 105 – 120 220 – 240 430 – 480

4 48 – 54 120 – 135 240 – 270 480 – 540

5 54 – 60 135 – 150 270 – 300 540 – 600

6 60 – 66 150 – 165 300 – 330 600 – 660

7 66 – 74 165 – 185 330 – 370 660 – 740

8 74 – 82 185 – 205 370 – 410 740 – 820

9 82 – 92 205 – 230 410 – 460 820 – 920

10 92 – 102 230 – 255 460 – 510 920 – 1020

11 102 – 114 255 – 285 510 – 570 1020 – 1140

12 114 – 130 285 – 325 570 – 650 1140 – 1300

SW1

FREQUENCY RANGE (kHz)*

1 ≤

< 2.4

2.4 ≤

< 4.8

4.8 ≤

< 12

1 0.85 – 0.95 1.7 – 1.9 3.4 – 3.8

2 0.95 – 1.05 1.9 – 2.2 3.8 – 4.4

3 1.05 – 1.20 2.2 – 2.4 4.4 – 4.8

4 1.20 – 1.35 2.4 – 2.7 4.8 – 5.4

5 1.35 – 1.50 2.7 – 3.0 5.4 – 6.0

6 1.50 – 1.65 3.0 – 3.3 6.0 – 6.6

7 1.65 – 1.85 3.3 – 3.7 6.6 – 7.4

8 1.85 – 2.05 3.7 – 4.1 7.4 – 8.2

9 2.05 – 2.30 4.1 – 4.6 8.2 – 9.2

10 2.30 – 2.55 4.6 – 5.1 9.2 – 10.2

11 2.55 – 2.85 5.1 – 5.7 10.2 – 11.4

12 2.85 – 3.25 5.7 – 6.5 11.4 – 13.0

* The frequency range can only be changed within the adjust-

ment range of the frequency variable range covering the

input range that you specified.

Example: If you specified the input range of 0 – 150 Hz

The range can be changed within 85 – 325 Hz.

■OUTPUT ZERO & SPAN ADJUSTMENT

1) Turn the bias adjustment (VR21) fully counterclockwise.

2) ZERO: With 0% input frequency, adjust output to 0

±0.05% with VR1.

3) SPAN: With 100% input frequency, adjust output to 100

±0.05% with VR22 after turning VR2 fully counterclock-

wise and then 1.5 turns clockwise.

4) Check ZERO adjustment again with 0% input frequency.

5) When ZERO value is changed, repeat the above proce-

dure 2) – 4).

MAINTENANCE

Regular calibration procedure is explained below:

■CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the “ADJUST-

MENT PROCEDURE” explained earlier.

LIGHTNING SURGE PROTECTION

M-System offers a series of lightning surge protector for

protection against induced lightning surges. Please contact

M-System to choose appropriate models.

6 PA

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4233 Rev.6 P. 3 / 3