5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8511 Rev.3 P. 1 / 3

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■PACKAGE INCLUDES:

Signal conditioner ...............................................................(1)

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■CONFORMITY WITH EU DIRECTIVES

• The equipment must be mounted inside a panel.

• The actual installation environments such as panel con-

figurations, connected devices, connected wires, may affect

the protection level of this unit when it is integrated in a

panel system. The user may have to review the CE re-

quirements in regard to the whole system and employ ad-

ditional protective measures* to ensure the CE conformity.

* For example, installation of noise filters and clamp fil-

ters for the power source, input and output connected

to the unit, etc.

• Install lightning surge protectors for those wires connect-

ed to remote locations.

■POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

85 – 264V AC rating: 85 – 264V, 47 – 66 Hz,

approx. 4 – 6VA

24V DC rating: 24V ±10%, approx. 3W

11 – 27V DC rating: 11 – 27V, approx. 3W

110V DC rating: 85 – 150V, approx. 3W

■GENERAL PRECAUTIONS

• Before you remove the unit or mount it, turn off the power

supply and input signal for safety.

■ENVIRONMENT

• Indoor use.

• When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 0 to 90% RH

in order to ensure adequate life span and operation.

■WIRING

• Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

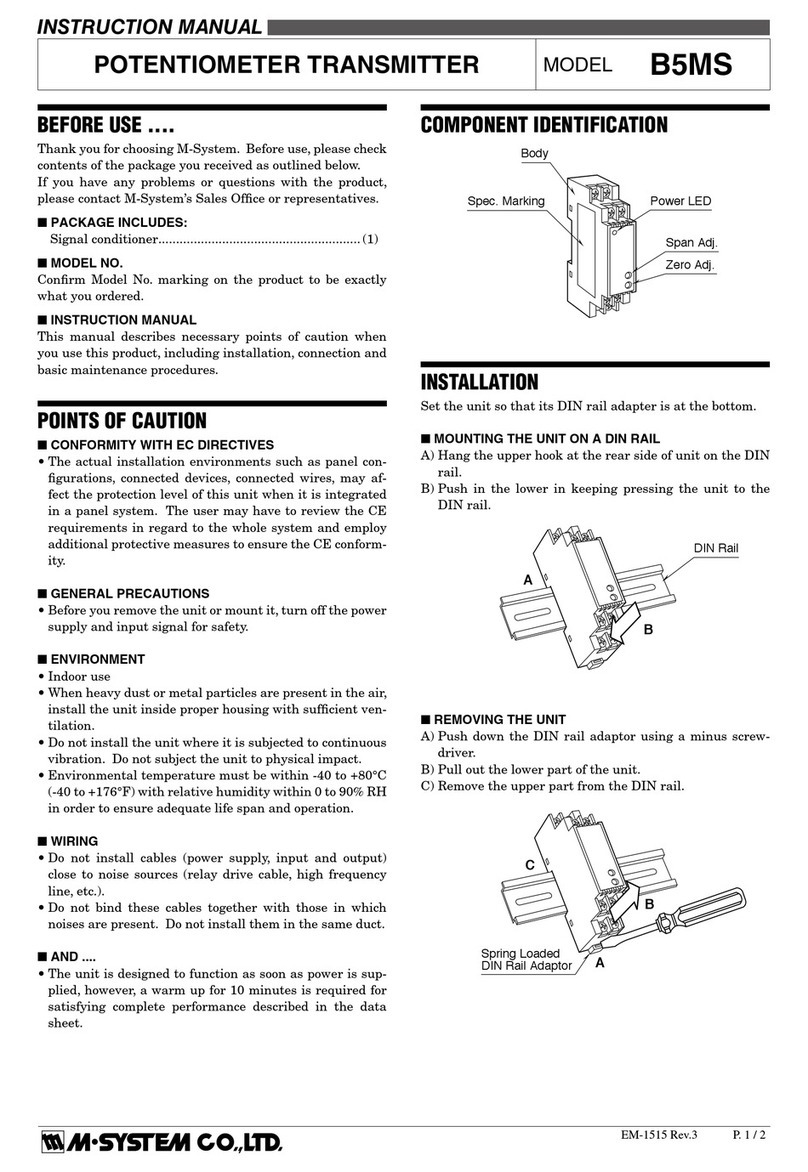

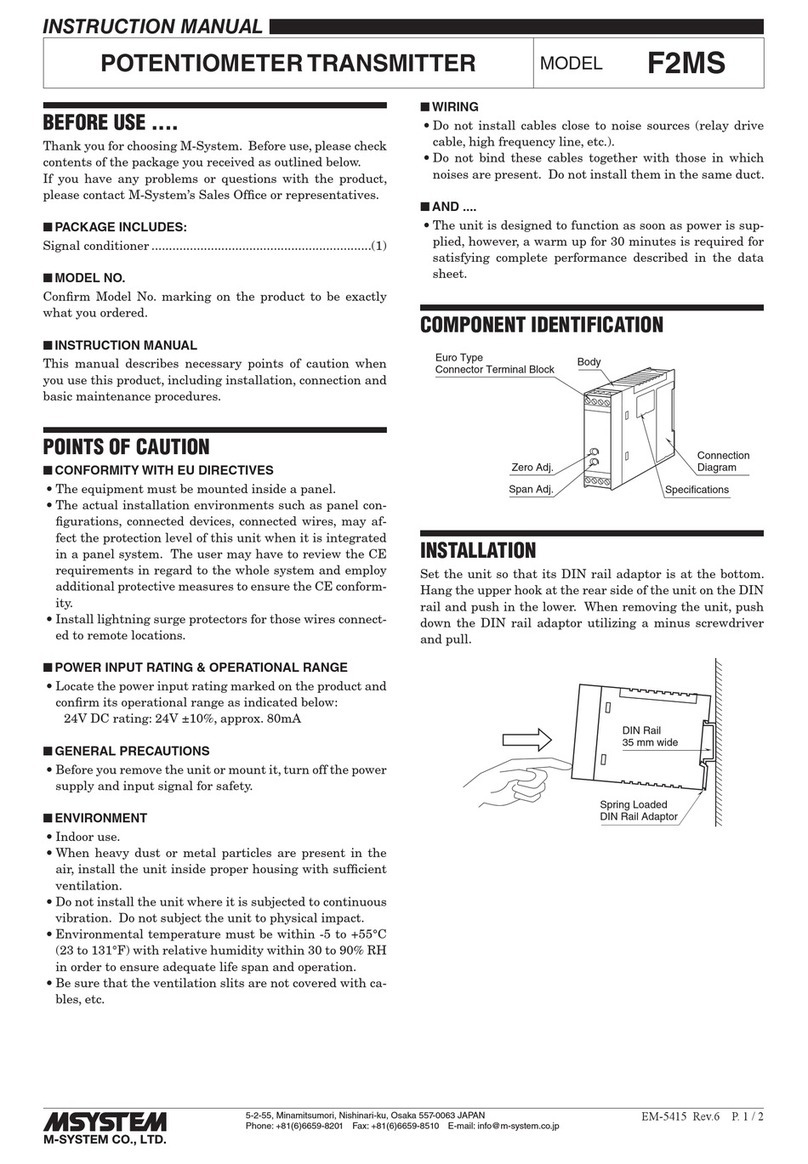

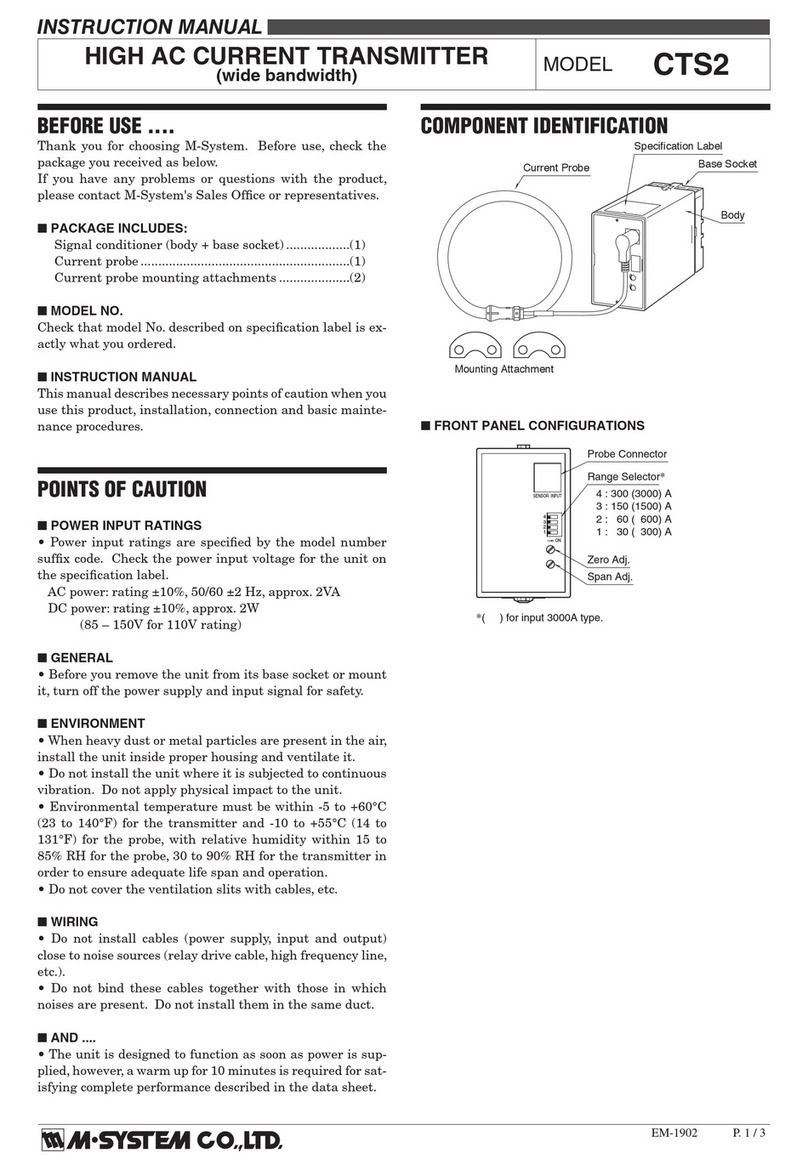

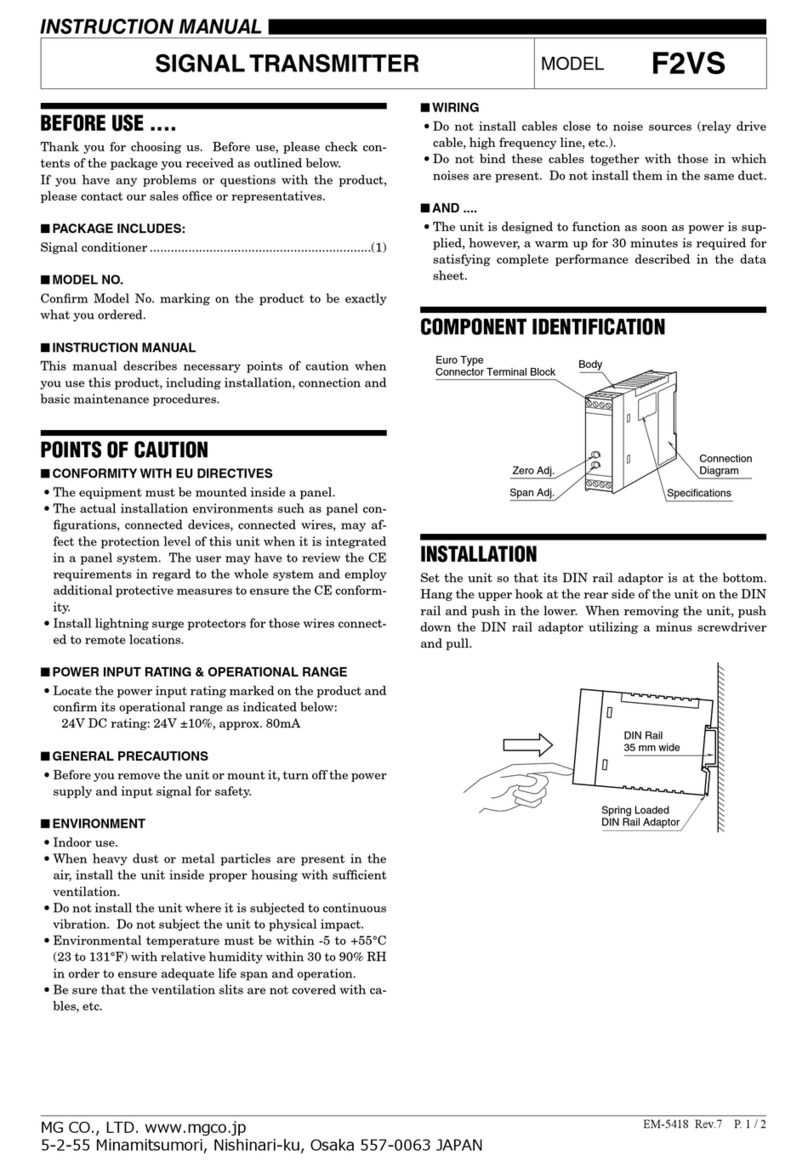

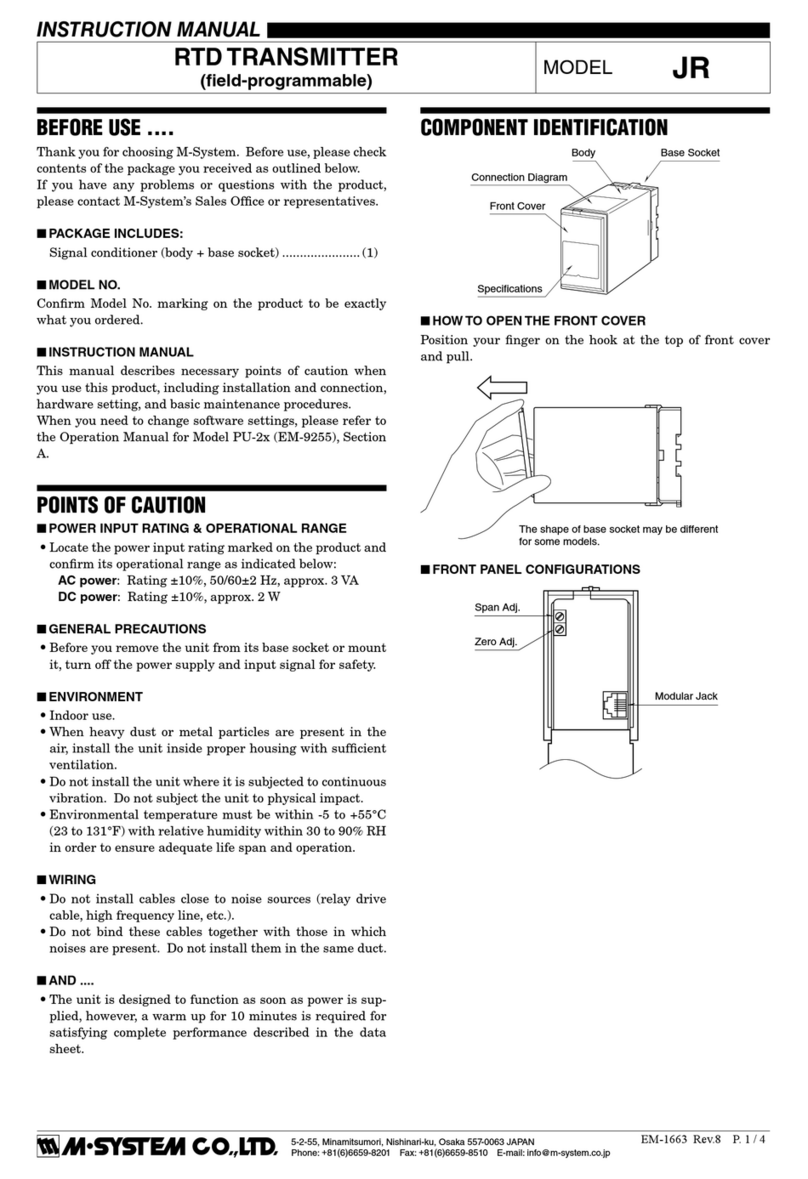

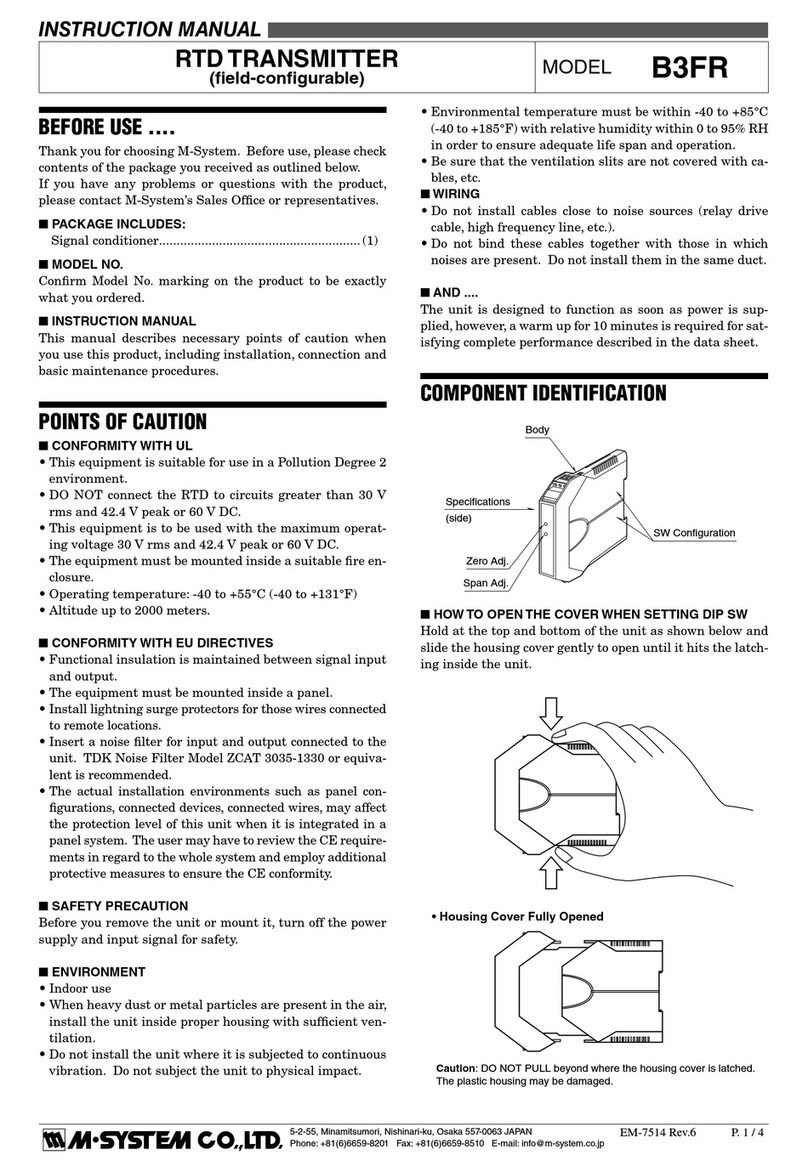

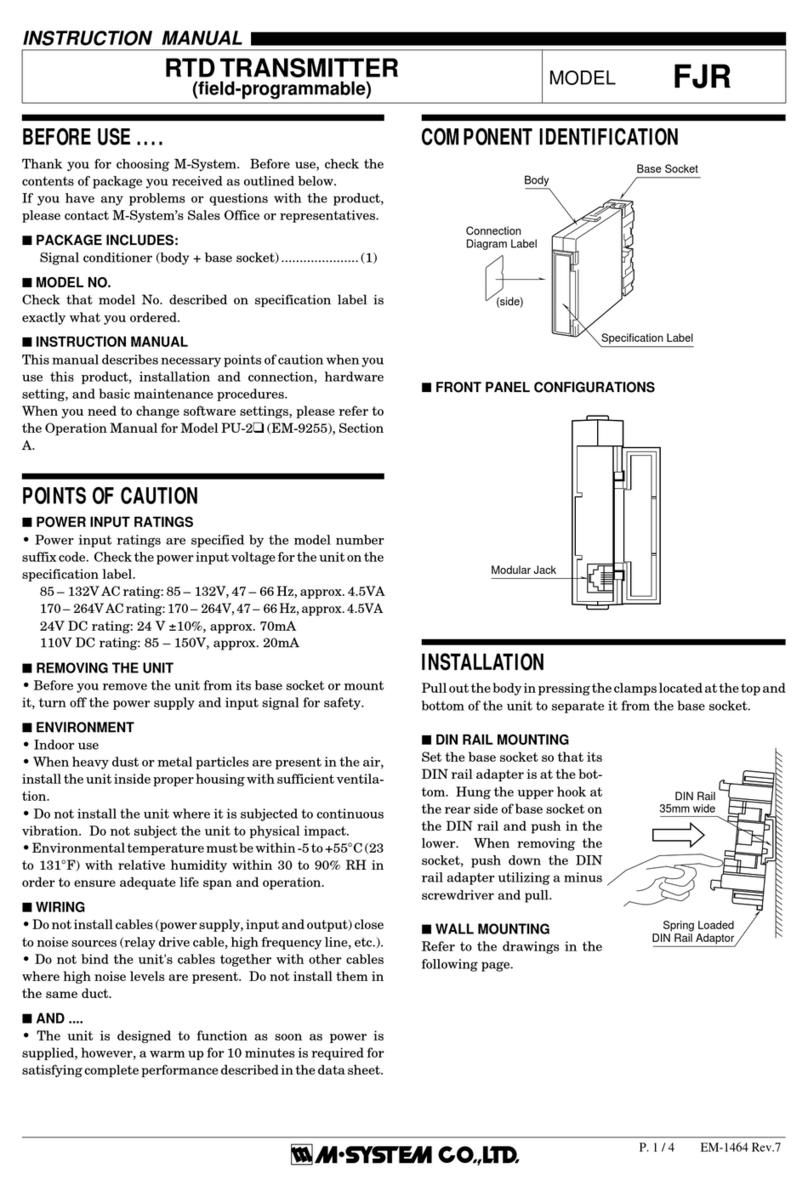

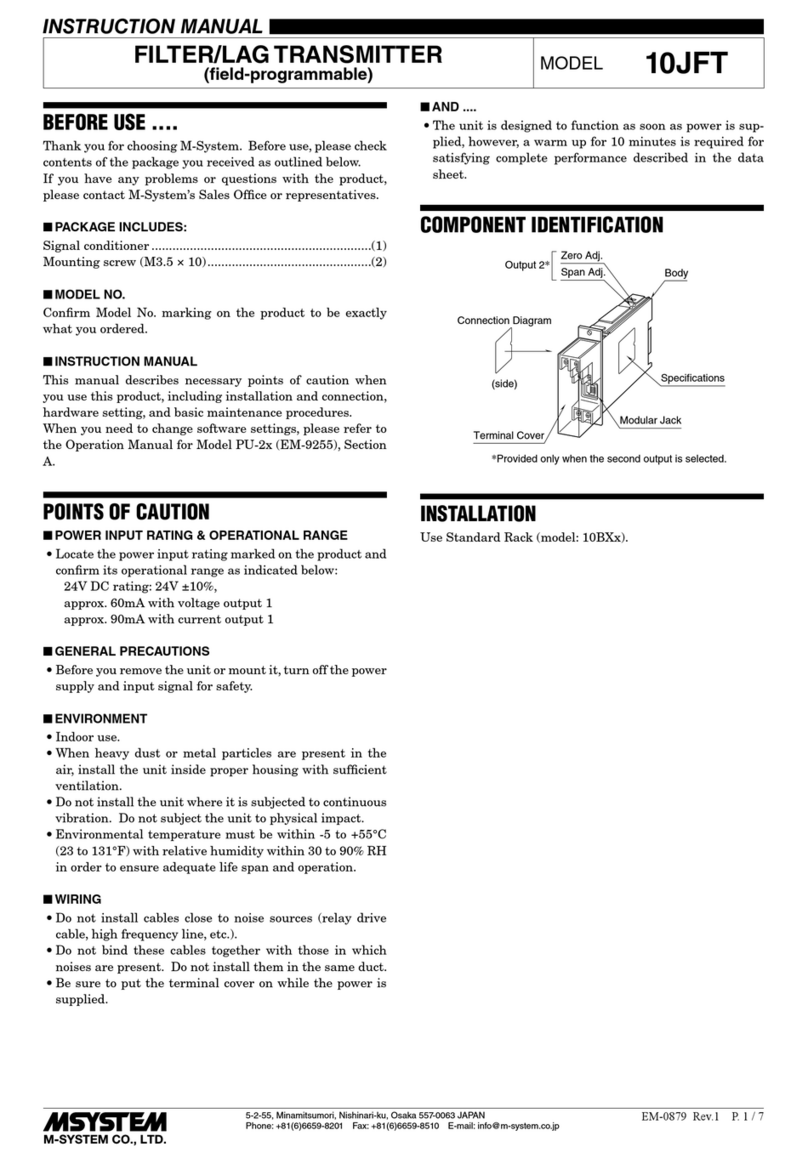

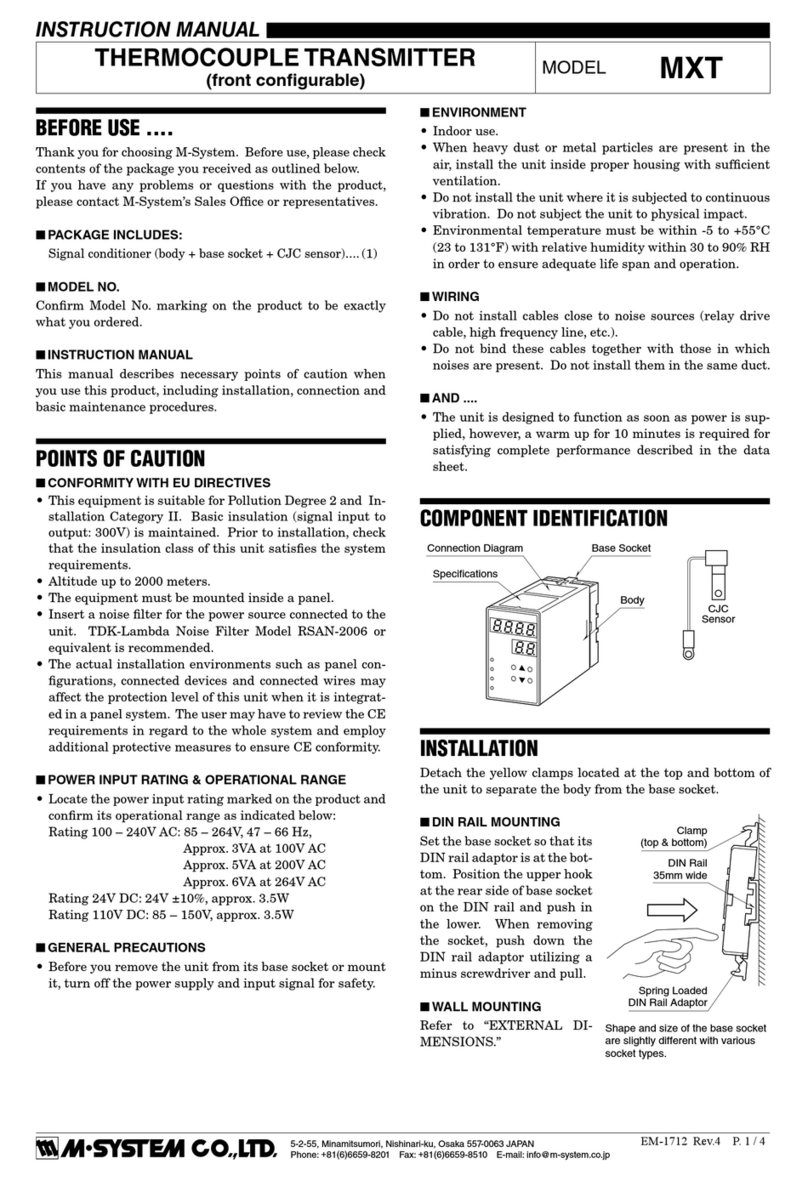

COMPONENT IDENTIFICATION

• Output 2

Span Adj.

Zero Adj.

• Output 1

Span Adj.

Zero Adj.

Body

Specifications

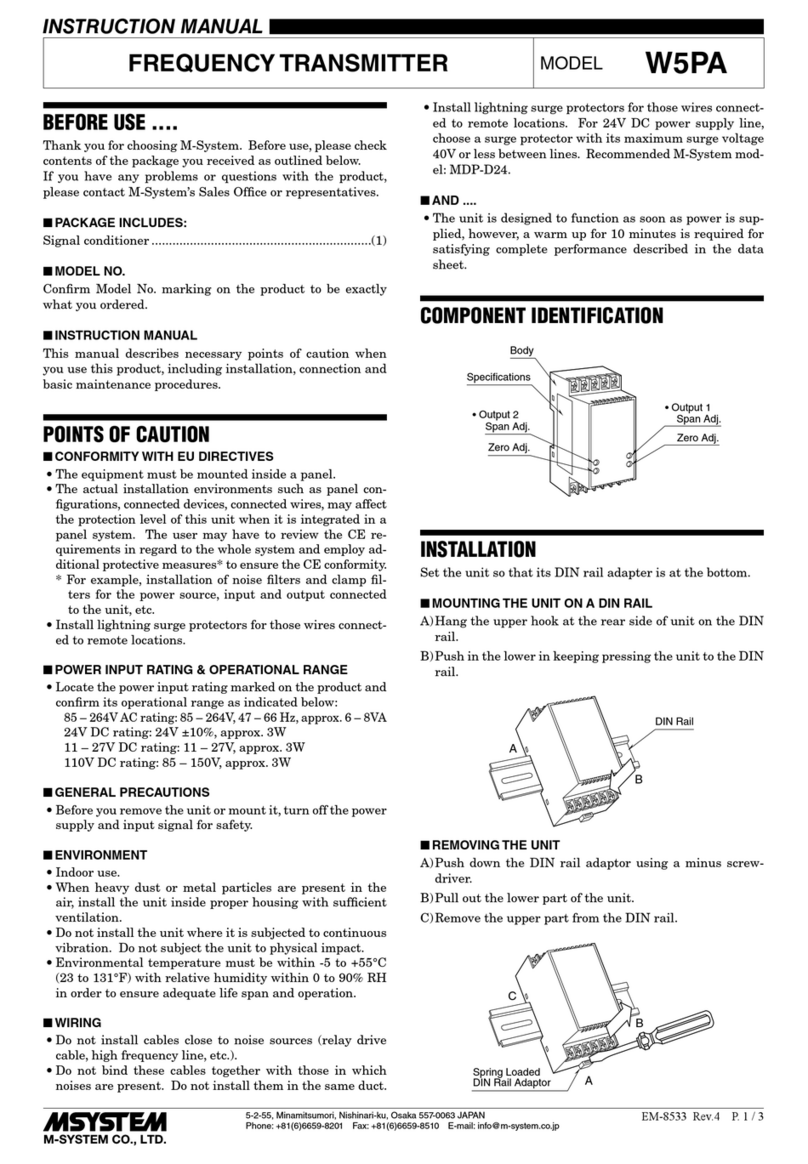

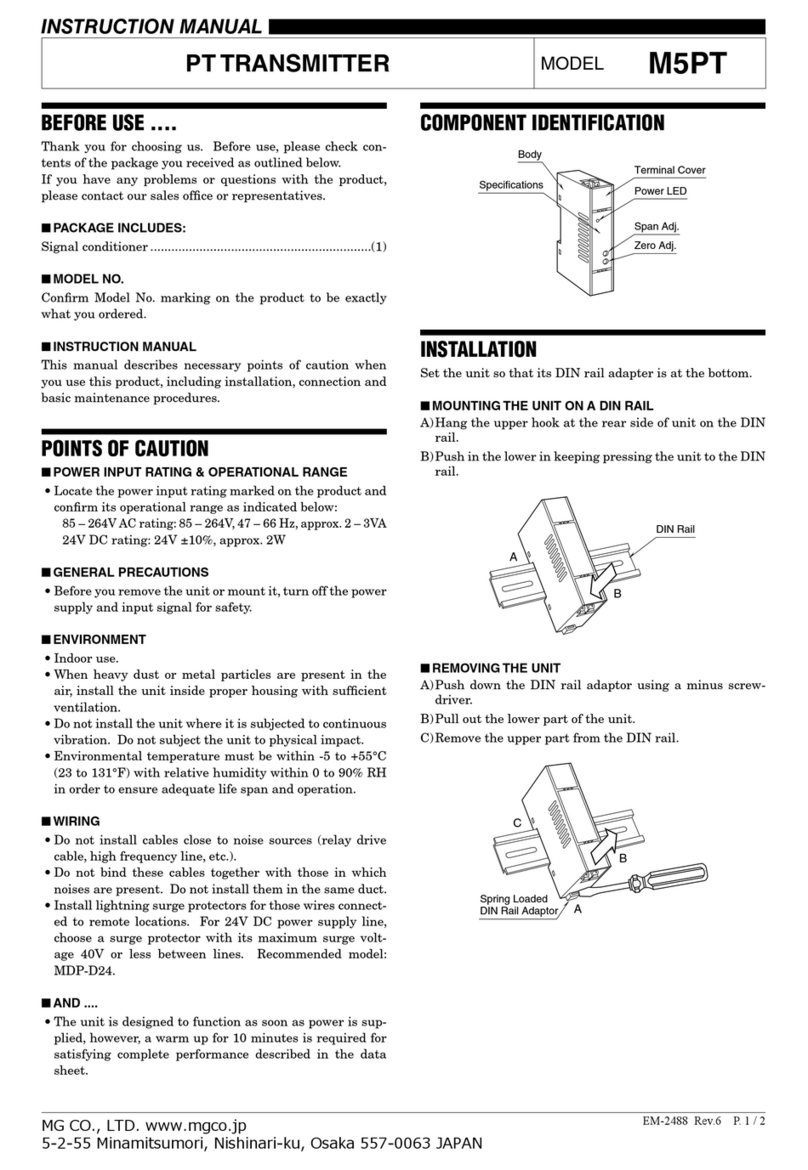

INSTALLATION

Set the unit so that its DIN rail adapter is at the bottom.

■MOUNTING THE UNIT ON A DIN RAIL

A)Hang the upper hook at the rear side of unit on the DIN

rail.

B)Push in the lower in keeping pressing the unit to the DIN

rail.

A

B

DIN Rail

■REMOVING THE UNIT

A)Push down the DIN rail adaptor using a minus screw-

driver.

B)Pull out the lower part of the unit.

C)Remove the upper part from the DIN rail.

C

A

B

Spring Loaded

DIN Rail Adaptor

POTENTIOMETER TRANSMITTER MODEL W5MS