TABLE OF CONTENTS

Section/Title Page

Form 169441 4Revision C

7.16.5Driving on Windrow .....................................................................................................................58

7.16.6Raking And Tedding....................................................................................................................58

7.16.7Chemical Drying Agents..............................................................................................................59

7.17DRAPER DEFLECTORS ....................................................................................................................60

7.17.1Deflector Replacement................................................................................................................60

7.17.2Deflector Re-work........................................................................................................................60

7.18KNIFE HEAD SHIELD.........................................................................................................................61

7.19HEADER LEVELLING.........................................................................................................................62

7.20UNPLUGGING CUTTERBAR .............................................................................................................62

7.21UPPER CROSS AUGER.....................................................................................................................63

7.22TRANSPORTING HEADER................................................................................................................64

7.22.1On The Windrower ......................................................................................................................64

7.22.2Towing.........................................................................................................................................64

7.22.3Converting from Transport to Field Position................................................................................65

7.22.4Converting from Field to Transport Position................................................................................70

7.23STORAGE...........................................................................................................................................72

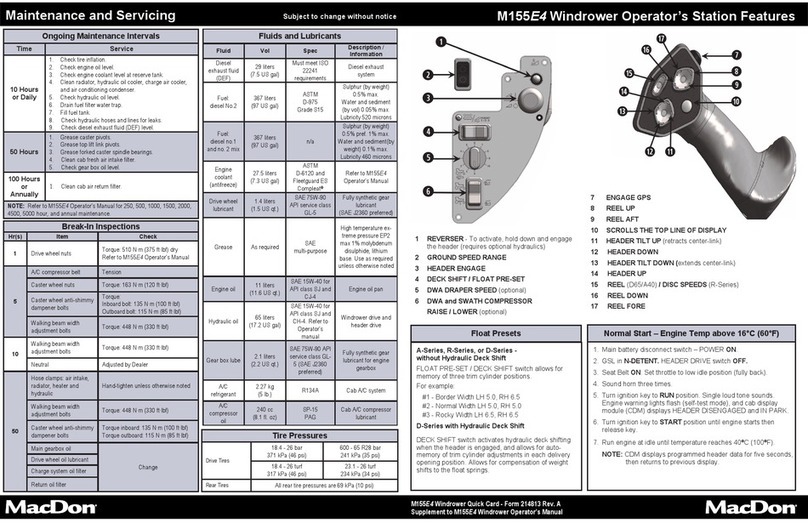

8MAINTENANCE AND SERVICING..............................................................................................................73

8.1PREPARATION FOR SERVICING .....................................................................................................73

8.2RECOMMENDED SAFETY PROCEDURES......................................................................................73

8.3MAINTENANCE SPECIFICATIONS ...................................................................................................74

8.3.1Recommended Torques..............................................................................................................74

8.3.2Roller Chain Installation...............................................................................................................77

8.3.3Sealed Bearing Installation..........................................................................................................77

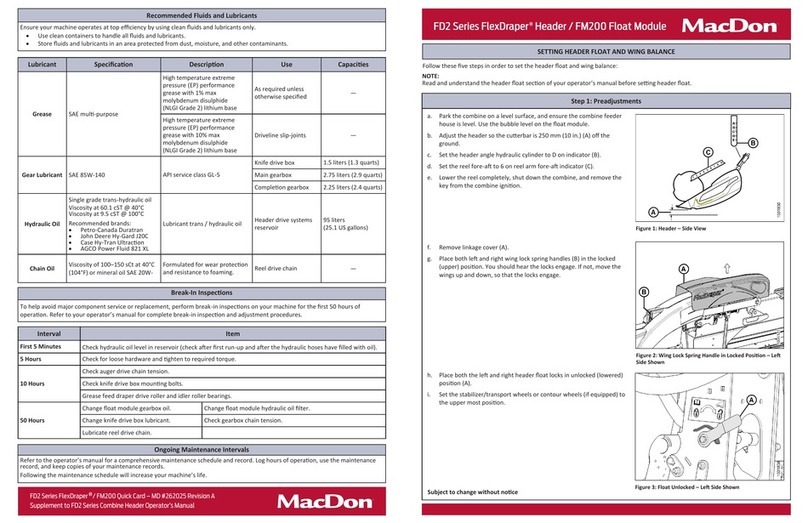

8.3.4Recommended Fluids and Lubricants.........................................................................................78

8.3.5Conversion Chart.........................................................................................................................78

8.4ENDSHIELDS......................................................................................................................................79

8.4.1Hinged .........................................................................................................................................79

8.4.2Non-Hinged .................................................................................................................................81

8.5LUBRICATION.....................................................................................................................................82

8.5.1Greasing Procedure ....................................................................................................................82

8.5.2Lubrication Points........................................................................................................................82

8.5.3Oiling Requirements....................................................................................................................88

8.5.4Hoses and Lines..........................................................................................................................89

8.5.5Hydraulic Schematics..................................................................................................................90

8.6ELECTRICAL.......................................................................................................................................94

8.7SICKLE AND SICKLE DRIVE .............................................................................................................95

8.7.1Sickle Sections............................................................................................................................95

8.7.2Sickle Removal............................................................................................................................96

8.7.3Sickle Head Bearing Replacement..............................................................................................96

8.7.4Sickle Installation.........................................................................................................................97

8.7.5Spare Sickle (Single Knife Headers)...........................................................................................97

8.7.6Sickle Guards ..............................................................................................................................98

8.7.7Sickle Hold-Downs ....................................................................................................................101

8.7.8Sickle Drive Belts: Non-Timed Drive.........................................................................................102

8.7.9Sickle Drive Belts: Timed Drive.................................................................................................103

8.7.10Wobble Box...............................................................................................................................108

8.8DRAPERS .........................................................................................................................................111

8.8.1Draper Tension Adjustment.......................................................................................................111

8.8.2Replacing Split Draper...............................................................................................................112

8.8.3Replacing Endless Draper.........................................................................................................113

8.8.4Draper Alignment.......................................................................................................................115

8.8.5Draper Roller Maintenance .......................................................................................................116

8.8.6Deck Height...............................................................................................................................119