214880 iv Revision A

3.9 Reconfiguring Cutterbar Crop Stream....................................................................................................... 47

3.9.1 Changing R216 SP Cutterbar Crop Stream Configuration ..................................................................... 48

3.10 Conditioner ....................................................................................................................................... 49

3.10.1 Roll Gap.................................................................................................................................... 49

Adjusting Roll Gap ...................................................................................................................... 49

3.10.2 Roll Tension .............................................................................................................................. 50

Adjusting Roll Tension ................................................................................................................. 50

3.10.3 Roll Timing ................................................................................................................................ 51

Checking Roll Timing ................................................................................................................... 51

Adjusting Roll Timing................................................................................................................... 51

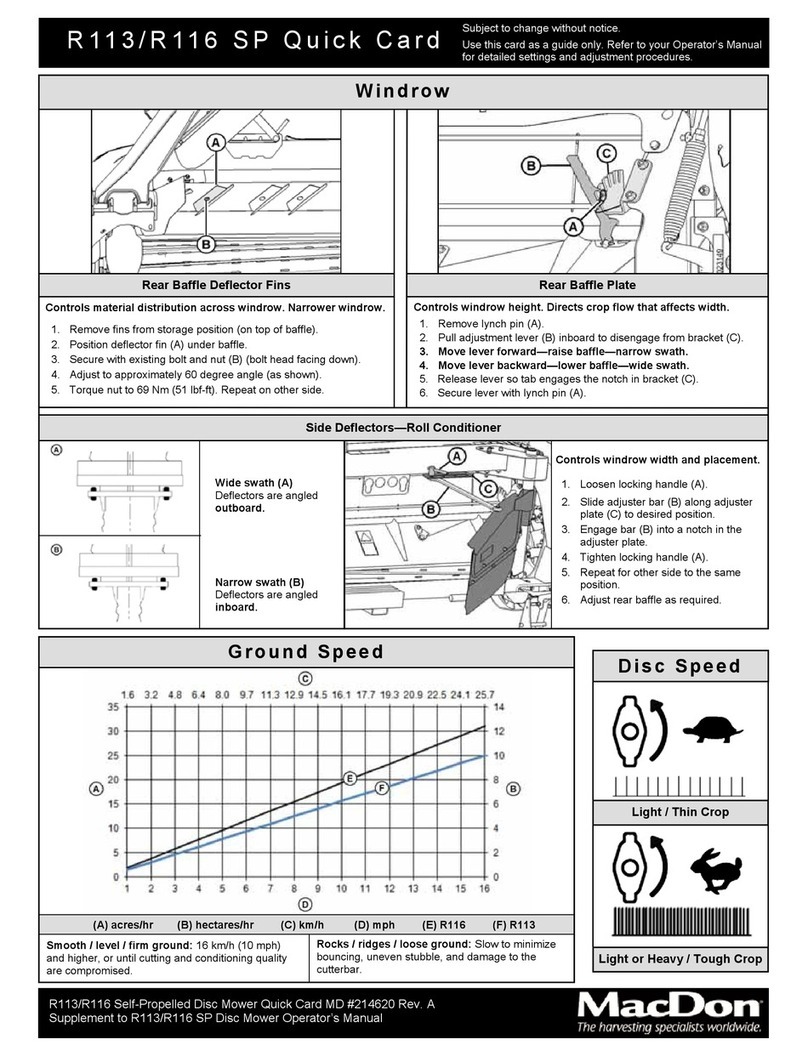

3.10.4 Adjusting Forming Shields –Roll Conditioner................................................................................... 54

Positioning Forming Shield Side Deflectors –Roll Conditioner............................................................. 54

Positioning Rear Baffle –Roll Conditioner ....................................................................................... 55

3.11 Haying Tips ........................................................................................................................................ 58

3.11.1 Curing ...................................................................................................................................... 58

3.11.2 Topsoil Moisture ........................................................................................................................ 58

3.11.3 Weather and Topography ............................................................................................................ 58

3.11.4 Windrow Characteristics.............................................................................................................. 59

3.11.5 Driving on Windrow.................................................................................................................... 59

3.11.6 Using Chemical Drying Agents ...................................................................................................... 59

3.12 Transporting the Header ...................................................................................................................... 60

Chapter 4: Maintenance and Servicing.................................................................................................... 61

4.1 Preparing Machine for Servicing.............................................................................................................. 61

4.2 Recommended Safety Procedures ........................................................................................................... 62

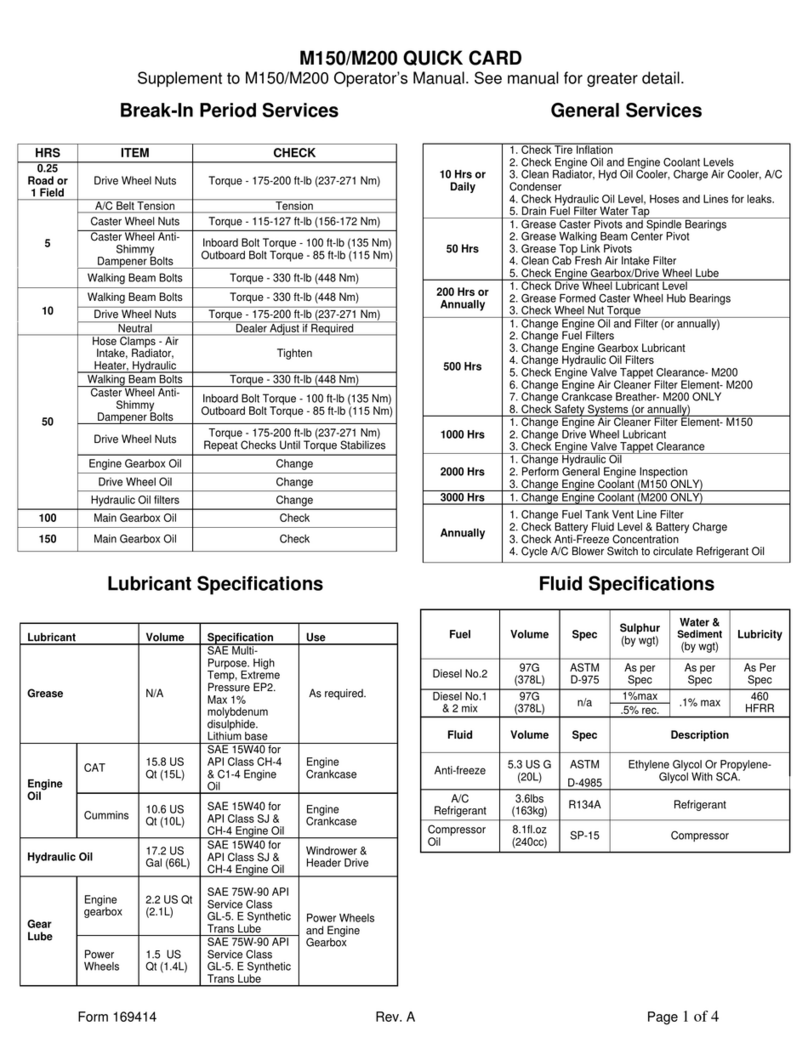

4.3 Maintenance Requirements ................................................................................................................... 64

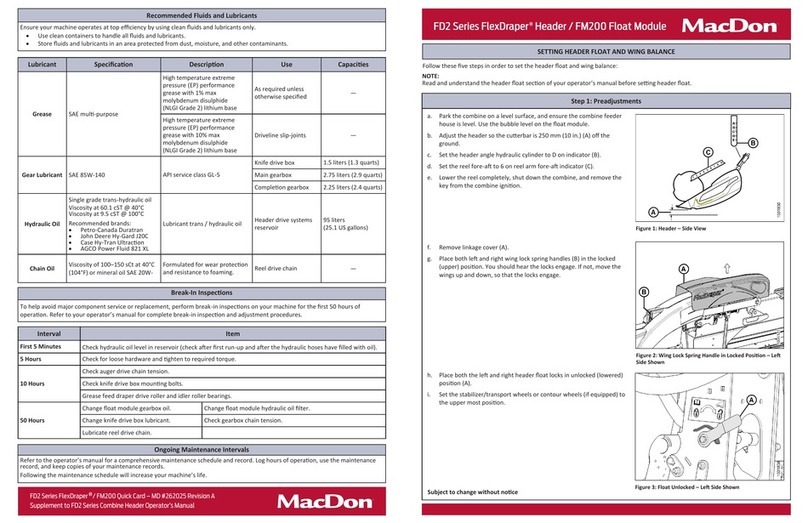

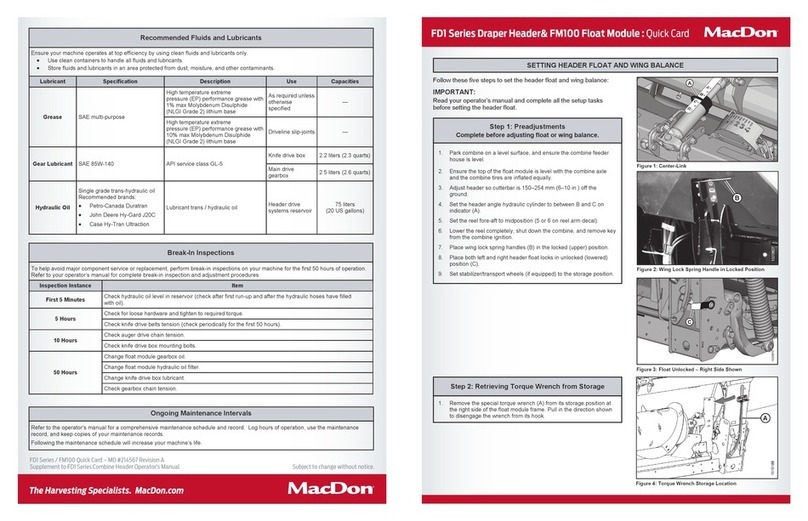

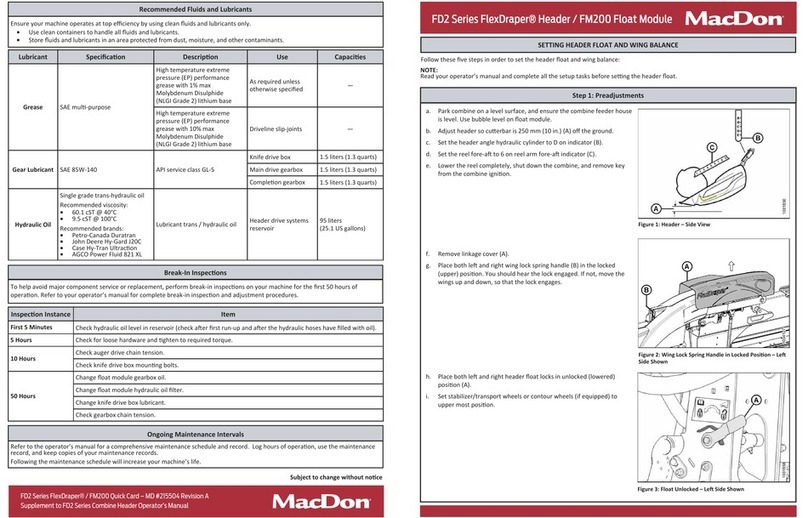

4.3.1 Maintenance Schedule/Record....................................................................................................... 64

4.3.2 Break-In Inspections ..................................................................................................................... 66

4.3.3 Preseason Servicing...................................................................................................................... 66

4.3.4 End-of-Season Servicing ................................................................................................................ 67

4.4 Lubrication .......................................................................................................................................... 68

4.4.1 Greasing Procedure ...................................................................................................................... 68

4.4.2 Lubrication Locations.................................................................................................................... 69

4.5 Cutterbar System.................................................................................................................................. 71

4.5.1 Lubricating Cutterbar.................................................................................................................... 71

Checking and Adding Cutterbar Lubricant ....................................................................................... 71

Draining the Cutterbar................................................................................................................. 74

Filling Lubricant into a Repaired Cutterbar ...................................................................................... 74

4.5.2 Maintaining Cutterbar Discs........................................................................................................... 75

Inspecting Cutterbar Discs ............................................................................................................ 76

Removing Cutterbar Discs ............................................................................................................ 77

Installing Cutterbar Discs.............................................................................................................. 78

4.5.3 Replacing Cutterbar Spindles.......................................................................................................... 80

Removing Cutterbar Spindles ........................................................................................................ 81

Installing Cutterbar Spindles ......................................................................................................... 83

4.5.4 Maintaining Discblades ................................................................................................................. 87

TABLE OF CONTENTS