R216 Rotary Disc Header – MD #215029 Revision A

Supplement to R216 Rotary Disc Header Operator’s Manual

Subject to change without noce

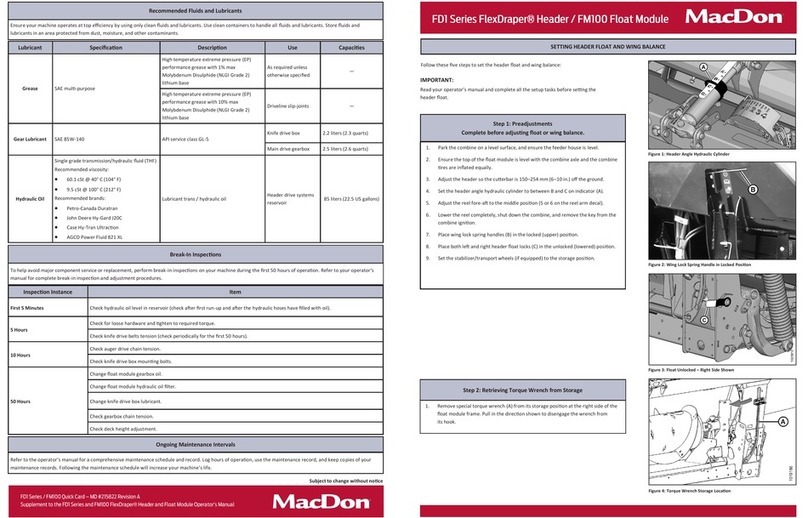

Adjusng the Condioner Rolls

Roll Gap Roll Tension

Increase condioning:

1. Loosen jam nut (A) on both sides of the condioner.

2. Turn lower nut (B) counterclockwise to decrease roll gap (C).

3. Tighten jam nut (A) on both sides of the condioner.

Decrease condioning:

1. Loosen jam nut (A) on both sides of the condioner.

2. Turn lower nut (B) clockwise to increase roll gap (C).

3. Tighten jam nut (A) on both sides of the condioner.

IMPORTANT: Ensure nuts are adjusted equally on both sides of the disc

header to achieve consistent gap across the rolls.

Decrease tension (light crops):

1. Loosen jam nut (A) on both sides of the condioner.

2. Turn bolt (B) counterclockwise to increase exposed thread (C)

equally on both sides of the condioner.

3. Tighten jam nut (A) on both sides of the condioner.

Increase tension (heavy or tough crops):

1. Loosen jam nut (A) on both sides of the condioner.

2. Turn bolt (B) clockwise to decrease exposed thread (C) equally on

both sides of the condioner.

3. Tighten jam nut (A) on both sides of the condioner.

Seng the Float

1. Lower header unl cuerbar is on the ground.

2. Adjust header lt to desired working angle.

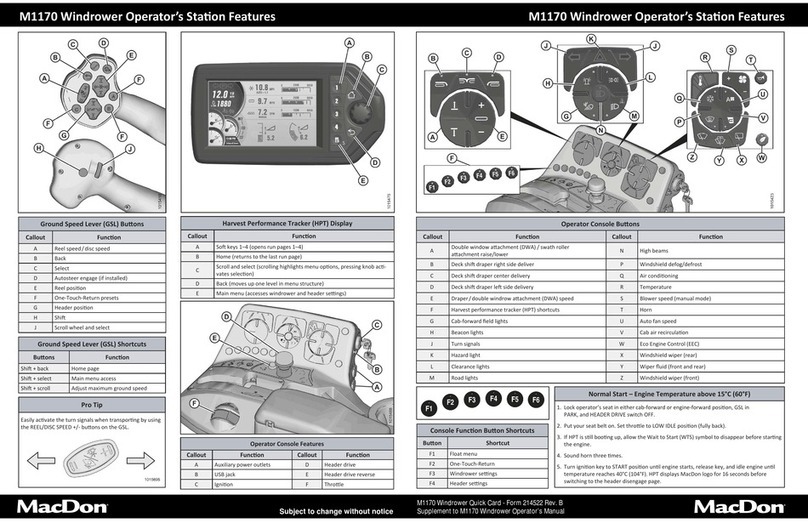

3. Press rotary scroll knob (A) on the HPT to display the QuickMenu

system.

4. Rotate scroll knob (A) to highlight header float icon (B), and press

scroll knob to select.

5. Turn scroll knob (A) to highlight lefloat (B) or right float (C).

6. Press knob (A) to acvate the selecon.

7. Rotate the scroll knob to adjust the float seng. Set float as light as

possible without excessive bouncing. Recommended starng seng

at 43–47 kg (95–105 lb.).

NOTE: Adjust the float in small increments.

8. Press the scroll knob when finished making adjustments.

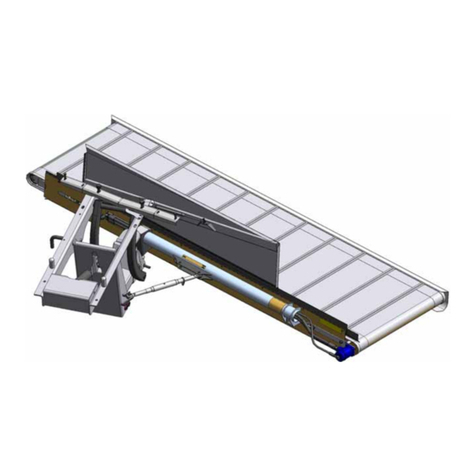

Adjusng Cung Height

Header Angle Skid Shoes

Shallow Angle Steep Angle Intermediate Posion Lower Posion

Use a shallow angle when the

ground is rocky, ridged, and loose

or uneven.

Use a steep angle when the ground

is firm, level, or smooth.

Use the upper posion when the

ground is smooth, or to produce a

short stubble.

Use the lower posion when the

ground is uneven, or to produce a

high stubble.