5

Caution

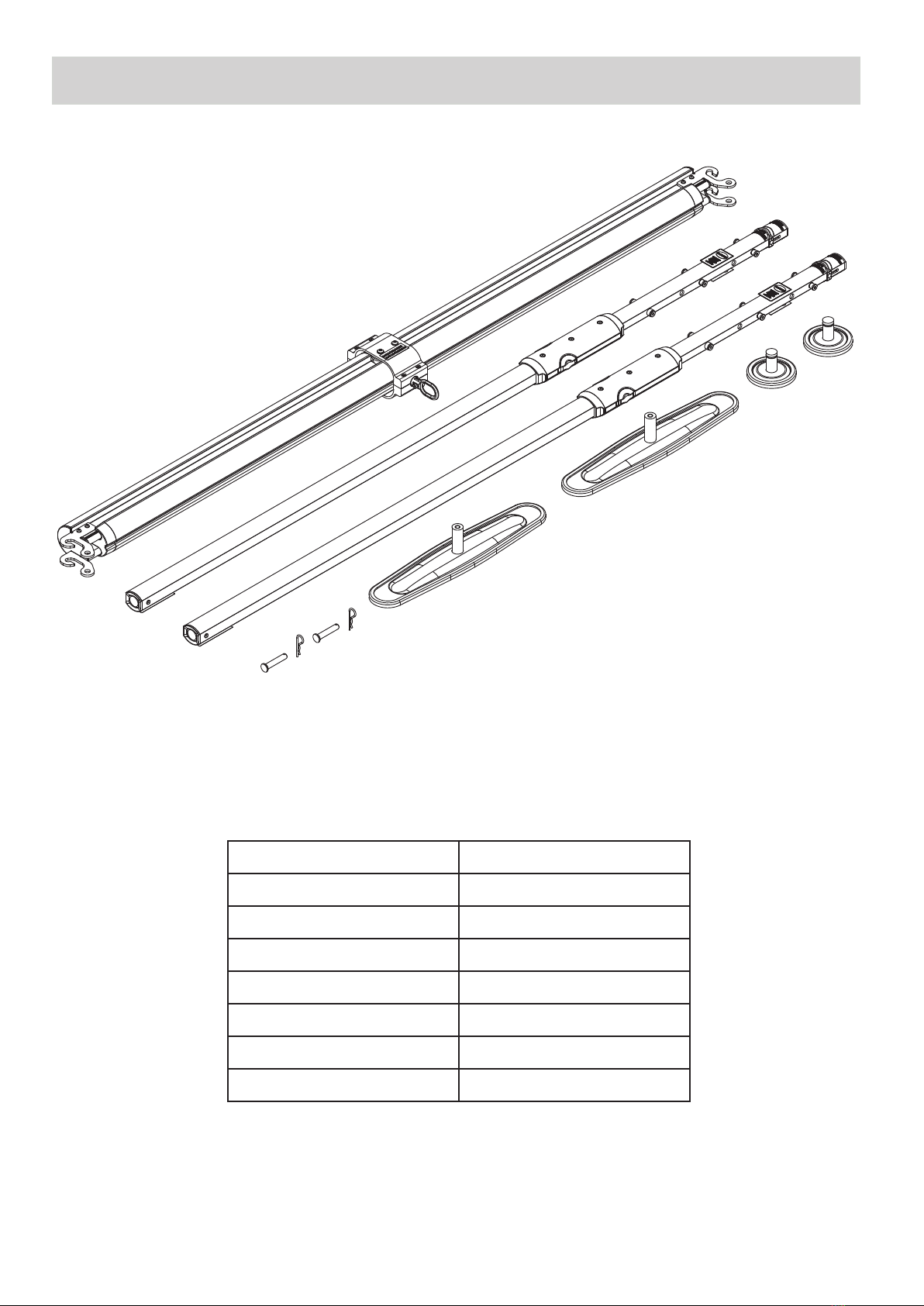

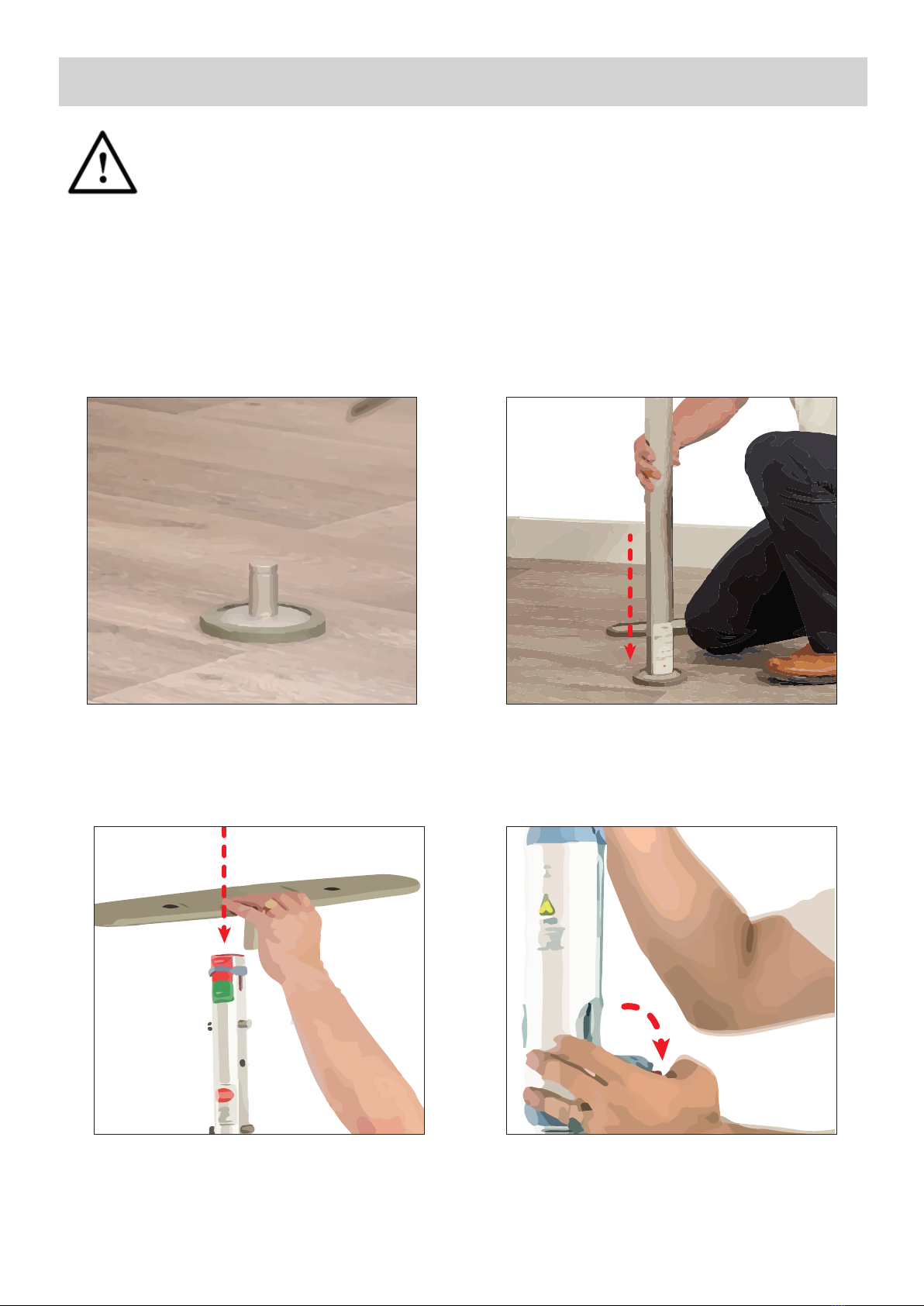

e Easy Fit System must be assembled prior to use. Should you have any questions

during assembly contact your local authorized dealer.

• Under no circumstance should the track, li and sling(s) or entire system be put in control of a person

who has not been properly trained in the use and care of this equipment. Failure to adhere to this warning

may result in serious injury to the operator, and/or the individual being lied/transferred.

• Never install the Bottom foot plate on the top portion of post section or vice versa. See section ‘Assembly’

instructions.

• e

Easy

Fit System and associated li and sling(s) are not toys. Do not use them for unsafe practices. Do

not allow children to play with this equipment or any of its components.

• e manufacturer’s warranty is void if persons unauthorized to perform work undertake this on the

Easy

Fit System.

• Ensurerubber feetarecleaned anddry priorto eachuse.Seesection “CleaningRubberBaseInstructions.”

• Ensure that the pressure gauge is in the safe zone during set up.

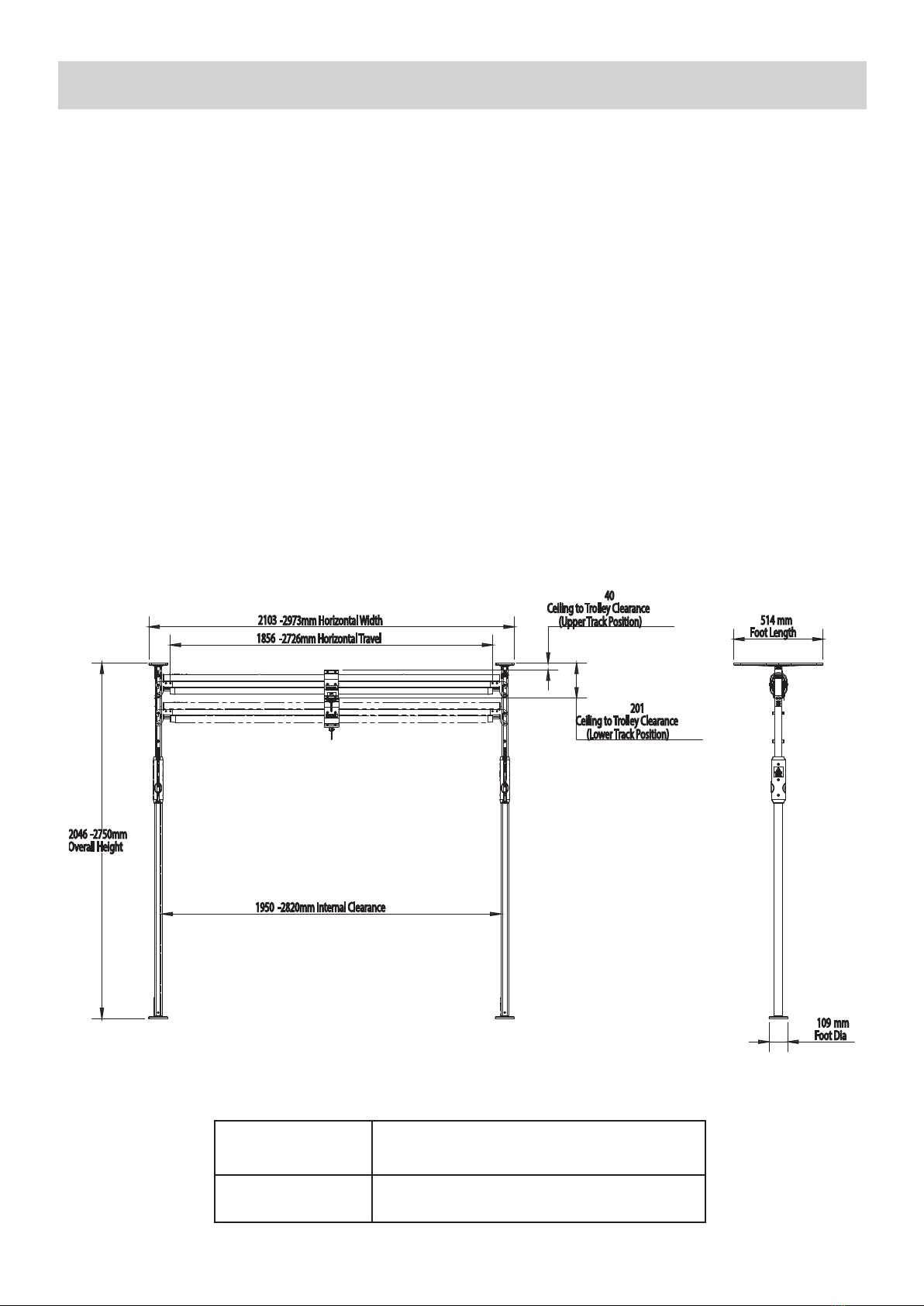

• Check the posts during installation are level both visually and with master spirit level.

• In places where more than one operator will be responsible for using the

Easy

Fit System, associated li

and sling(s), it is imperative that all operators be trained in its proper use.

• Never expose the Easy Fit directly to water. Warranty does not cover any misuse or abuse of the Easy Fit

system.

• To maintain optimum function, the

Easy

Fit should be inspected and maintained on a regular basis. See

the section titled “Pre-Use Inspection and Maintenance”.

• Any accessories used with the

Easy

Fit System including li and sling(s), should be checked to ensure

that they are in good working order. Check for signs of wear or fraying prior to use. Report any unusual

wear or damage immediately to your local authorized dealer.

• e

Easy

Fit System and associated li, and sling(s) are intended only for liing and transferring of

a person. e manufacturer will not be responsible for any damage caused by the misuse, neglect or

purposeful destruction of the li and/or its associated components.

• Do not in any circumstance exceed the maximum load for this piece of equipment. Refer to the

“Specications of the

Easy

Fit System” section of this manual.

• e installation of the

Easy

Fit System, li, accessories, and sling are certied to a maximum load. Do not

exceed the maximum rated load of any of the components.

• Ensure that a clear space is maintained around the

Easy

Fit System. Remove all furniture and other

obstacles out of the way before performing a transfer.

• e

Easy

Fit System has been designed to li vertically at its maximum load and at maximum height. Do

not attempt to li an individual at an angle to the track.