4ENGLISH

6. Keep cutting tools sharp and clean.Properly

maintained cutting tools with sharp cutting edges

arelesslikelytobindandareeasiertocontrol.

7. Use the power tool, accessories and tool bits

etc. in accordance with these instructions, tak-

ing into account the working conditions and

the work to be performed. Use of the power tool

foroperationsdierentfromthoseintendedcould

result in a hazardous situation.

8. Keep handles and grasping surfaces dry,

clean and free from oil and grease.Slippery

handles and grasping surfaces do not allow for

safe handling and control of the tool in unexpected

situations.

9. When using the tool, do not wear cloth work

gloves which may be entangled. The entangle-

mentofclothworkglovesinthemovingpartsmay

resultinpersonalinjury.

Battery tool use and care

1. Recharge only with the charger specied by

the manufacturer. Acharger that is suitable for

onetypeofbatterypackmaycreateariskofre

whenusedwithanotherbatterypack.

2. Use power tools only with specically desig-

nated battery packs.Useofanyotherbattery

packsmaycreateariskofinjuryandre.

3. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another.Shortingthebatterytermi-

nalstogethermaycauseburnsorare.

4. Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If con-

tact accidentally occurs, ush with water. If

liquid contacts eyes, additionally seek medical

help.Liquidejectedfromthebatterymaycause

irritation or burns.

5. Do not use a battery pack or tool that is dam-

aged or modied.Damagedormodiedbatteries

mayexhibitunpredictablebehaviourresultingin

re,explosionorriskofinjury.

6. Do not expose a battery pack or tool to re or

excessive temperature.Exposuretoreortem-

peratureabove130°Cmaycauseexplosion.

7. Follow all charging instructions and do not

charge the battery pack or tool outside the

temperature range specied in the instruc-

tions.Chargingimproperlyorattemperatures

outsidethespeciedrangemaydamagethe

batteryandincreasetheriskofre.

Service

1. Have your power tool serviced by a qualied

repair person using only identical replacement

parts.Thiswillensurethatthesafetyofthepower

tool is maintained.

2. Never service damaged battery packs. Service

ofbatterypacksshouldonlybeperformedbythe

manufacturer or authorized service providers.

3. Follow instruction for lubricating and chang-

ing accessories.

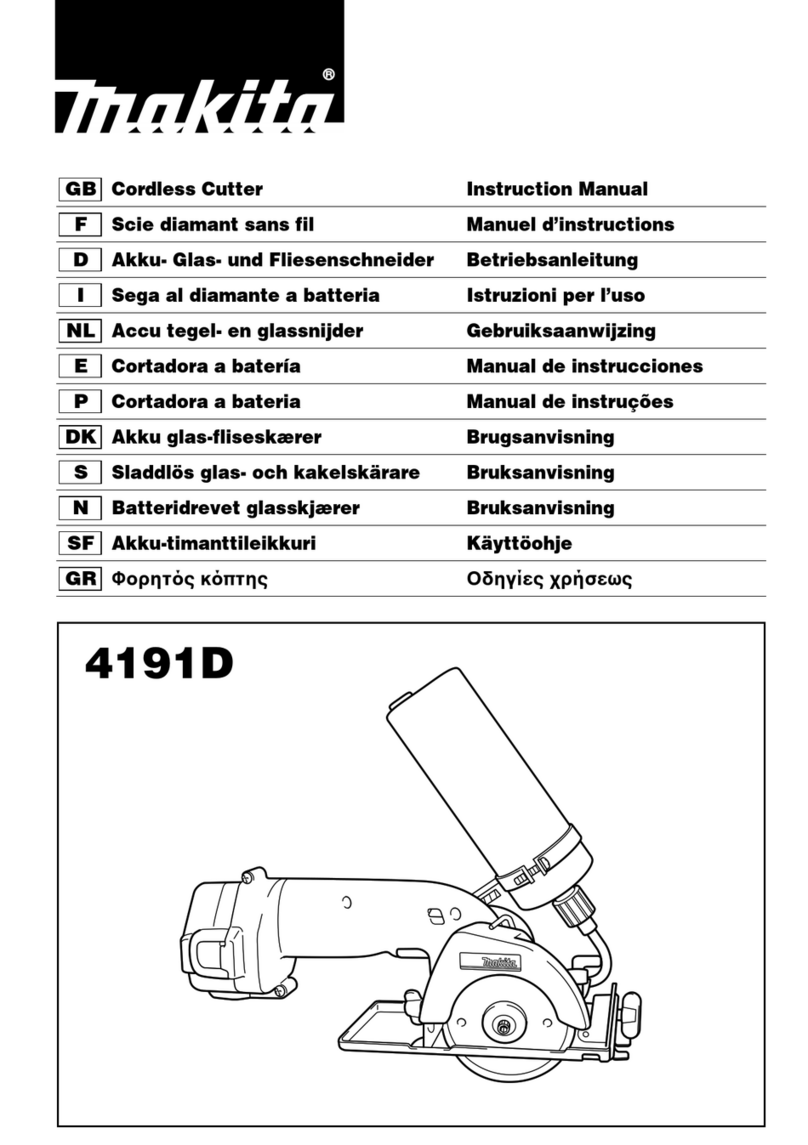

Cordless cutter safety warnings

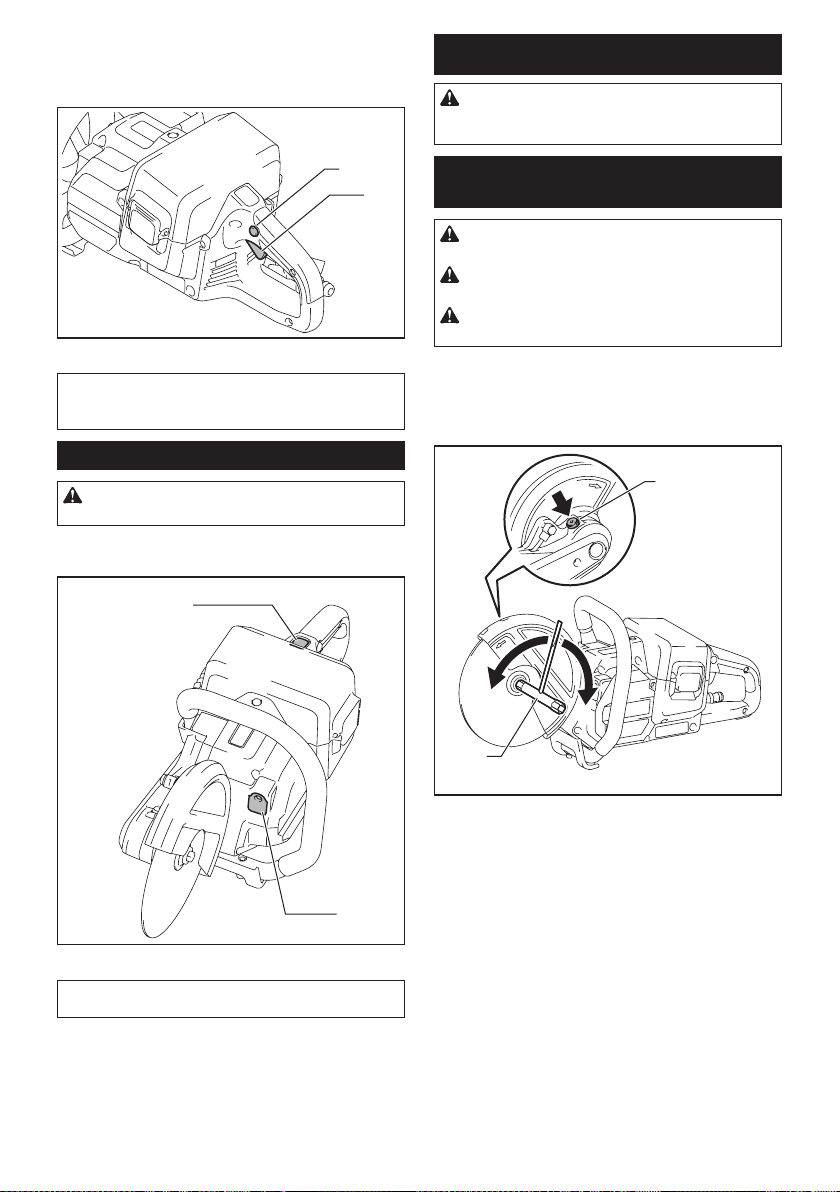

1. The guard provided with the tool must be

securely attached to the power tool and

positioned for maximum safety, so the least

amount of wheel is exposed towards the oper-

ator. Position yourself and bystanders away

from the plane of the rotating wheel. The guard

helps to protect operator from broken wheel frag-

ments and accidental contact with wheel.

2. Use only bonded reinforced or diamond cut-o

wheels for your power tool. Just because an

accessorycanbeattachedtoyourpowertool,it

does not assure safe operation.

3. The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

theirratedspeedcanbreakandyapart.

4. Wheels must be used only for recommended

applications. For example: do not grind with

the side of cut-o wheel.Abrasivecut-owheels

are intended for peripheral grinding, side forces

appliedtothesewheelsmaycausethemto

shatter.

5. Always use undamaged wheel anges that are

of correct diameter for your selected wheel.

Properwheelangessupportthewheelthus

reducingthepossibilityofwheelbreakage.

6. Do not use worn down reinforced wheels from

larger power tools. Wheels intended for a larger

power tool are not suitable for the higher speed of

asmallertoolandmayburst.

7. The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool.Incorrectlysizedaccessories

cannotbeadequatelyguardedorcontrolled.

8. The arbour size of wheels and anges must

properly t the spindle of the power tool.

Wheelsandangeswitharbourholesthatdonot

match the mounting hardware of the power tool

willrunoutofbalance,vibrateexcessivelyand

maycauselossofcontrol.

9. Do not use damaged wheels. Before each

use, inspect the wheels for chips and cracks.

If power tool or wheel is dropped, inspect for

damage or install an undamaged wheel. After

inspecting and installing the wheel, position

yourself and bystanders away from the plane

of the rotating wheel and run the power tool

at maximum no load speed for one minute.

Damagedwheelswillnormallybreakapartduring

this test time.

10. Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As appro-

priate, wear dust mask, hearing protectors,

gloves and shop apron capable of stopping

small abrasive or workpiece fragments. The

eyeprotectionmustbecapableofstoppingying

debrisgeneratedbyvariousoperations.Thedust

maskorrespiratormustbecapableofltrating

particlesgeneratedbyyouroperation.Prolonged

exposuretohighintensitynoisemaycausehear-

ing loss.