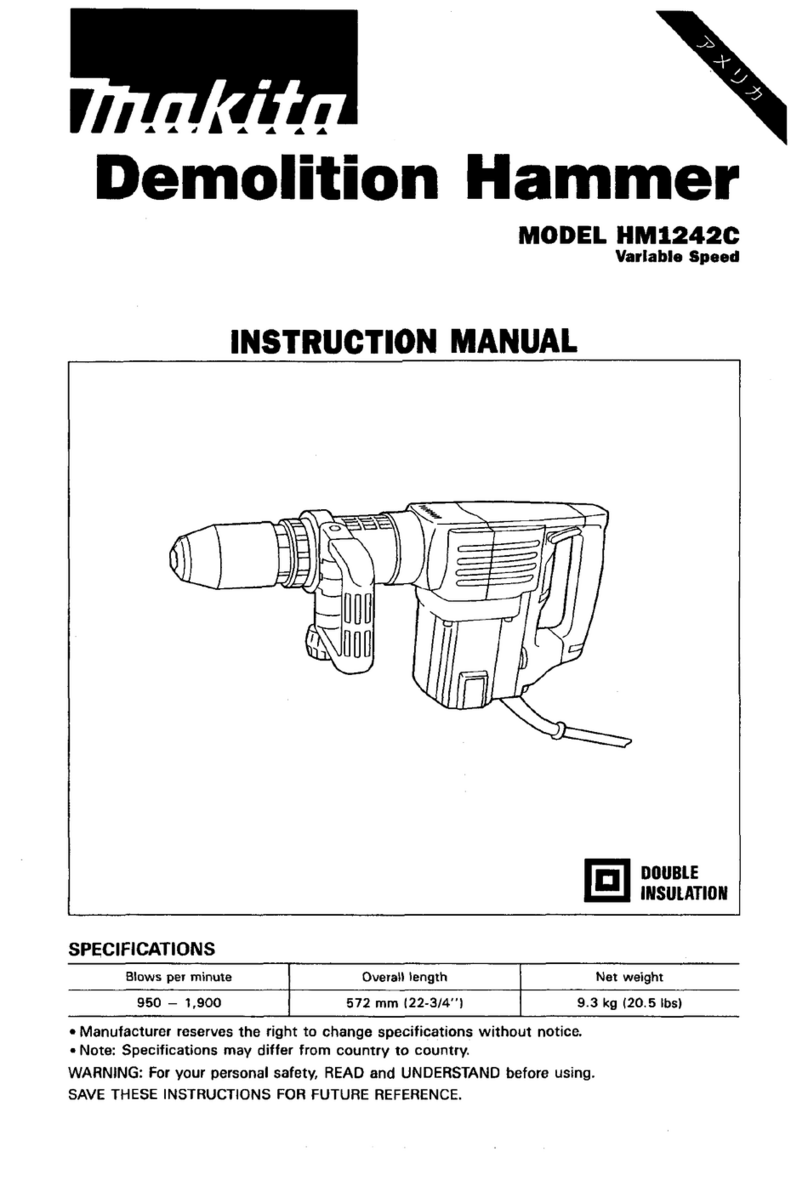

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output(W)

120 6.3 50 / 60 720 320 700

220 3.4 50 / 60 720 320 700

230 3.3 50 / 60 720 320 700

240 3.2 50 / 60 720 320 700

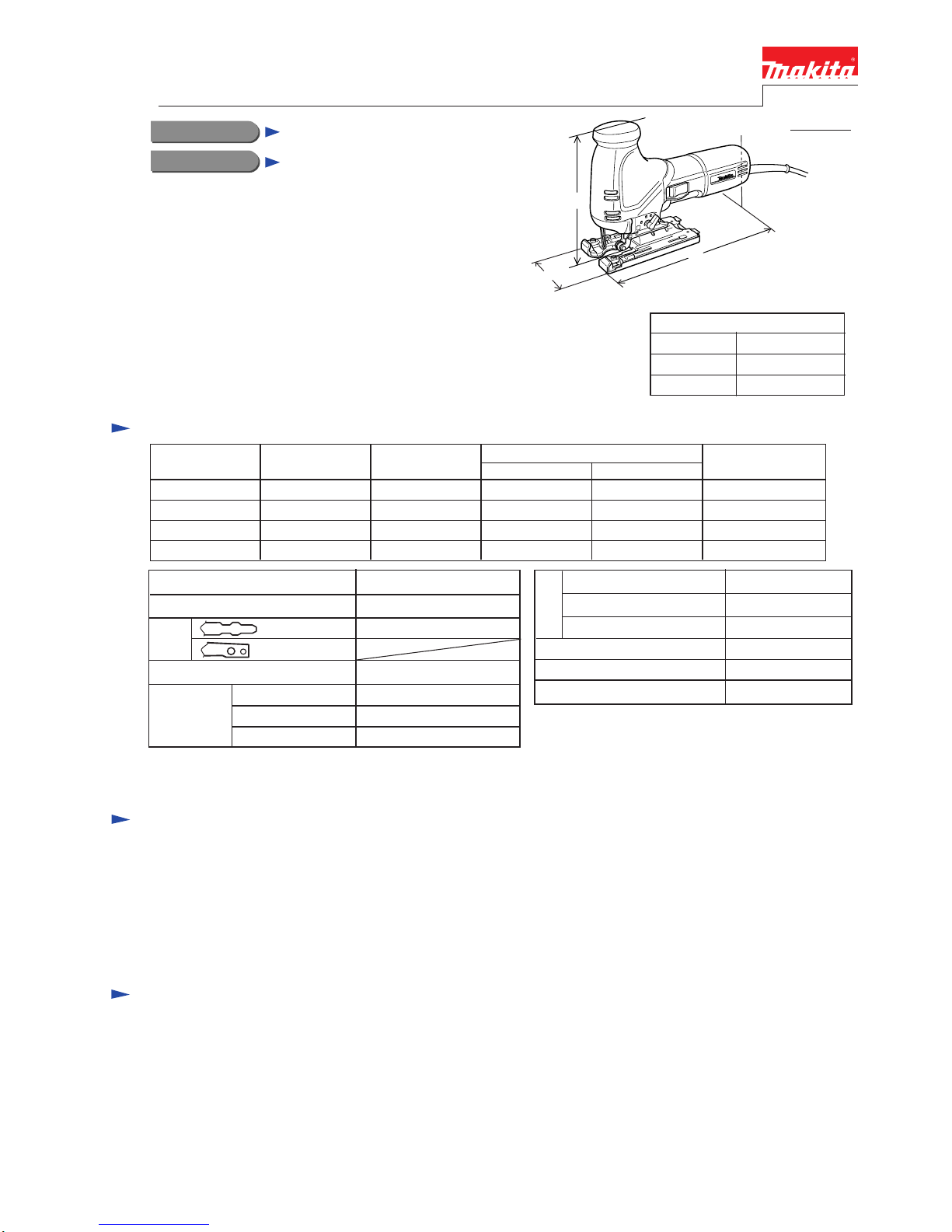

Model No.

Description

PRODUCT

Current (A)

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 / 14

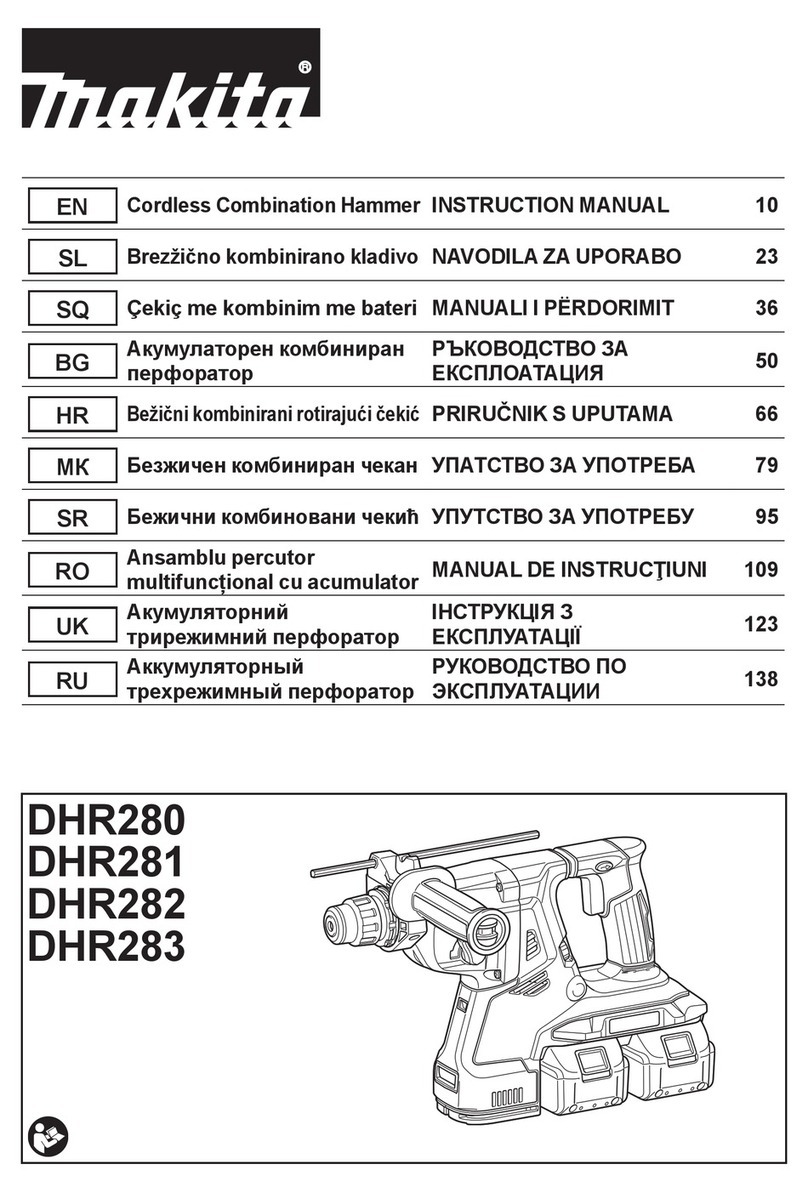

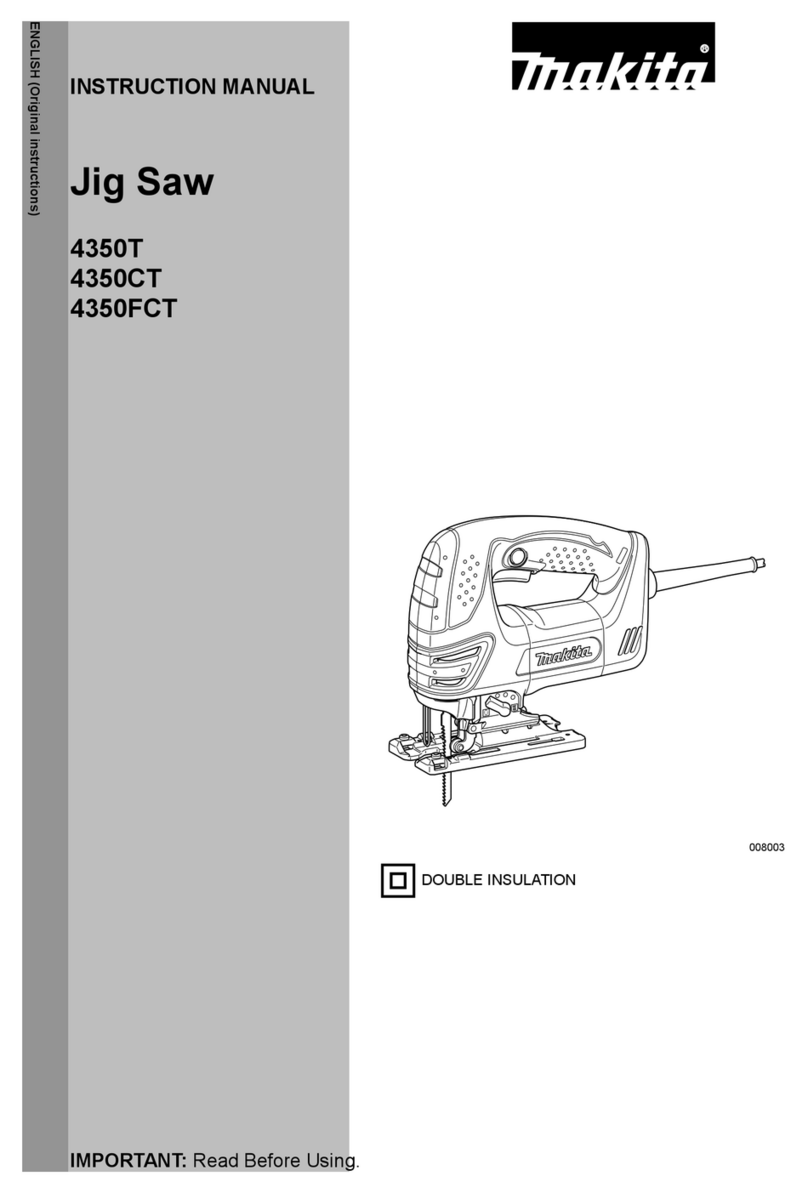

4341CT, 4341FCT

Jig saw

H

W

L

Dimensions : mm ( " )

Width ( W )

Height ( H )

Length ( L ) 271 (10-11/16)

188 (7-3/8)

73 (2-7/8)

* Jig saw blade set (including B-10: 2 pcs., BR-13: 2 pcs., B-22: 2 pcs.)......... 1 set

* Cover plate ..................................................................................................... 1 pc.

* Kerf board ..................................................................................................... 1 pc.

* Hex wrench ..................................................................................................... 1 pc.

* Dust nozzle (only for Europe) ......................................................................... 1 pc.

* Plastic carrying case ........................................................................................ 1 pc.

* Guide rule

* Guide rail set

* Guide rail adaptor

* Kerf board

* Dust nozzle

* Hose

* Jig saw blade No.51

* Jig saw blade No.58

* Jig saw blade No.B-8

* Jig saw blade No.B-10

* Jig saw blade No.B-11

* Jig saw blade No.B-12

* Jig saw blade No.B-13

* Jig saw blade No.B-14

* Jig saw blade No.B-15

* Jig saw blade No.B-16

* Jig saw blade No.B-17

* Jig saw blade No.B-18

* Jig saw blade No.B-19

* Jig saw blade No.B-21

* Jig saw blade No.B-22

* Jig saw blade No.B-23

* Jig saw blade No.B-24

* Jig saw blade No.B-25

* Jig saw blade No.B-26

* Jig saw blade No.B-27

* Jig saw blade No.B-16L

* Jig saw blade No.BR-13

* Plastic base plate

The above mentioned body handle type jig saw is the

advanced version of the existing model 4305T series.

Its brief benefits and features are

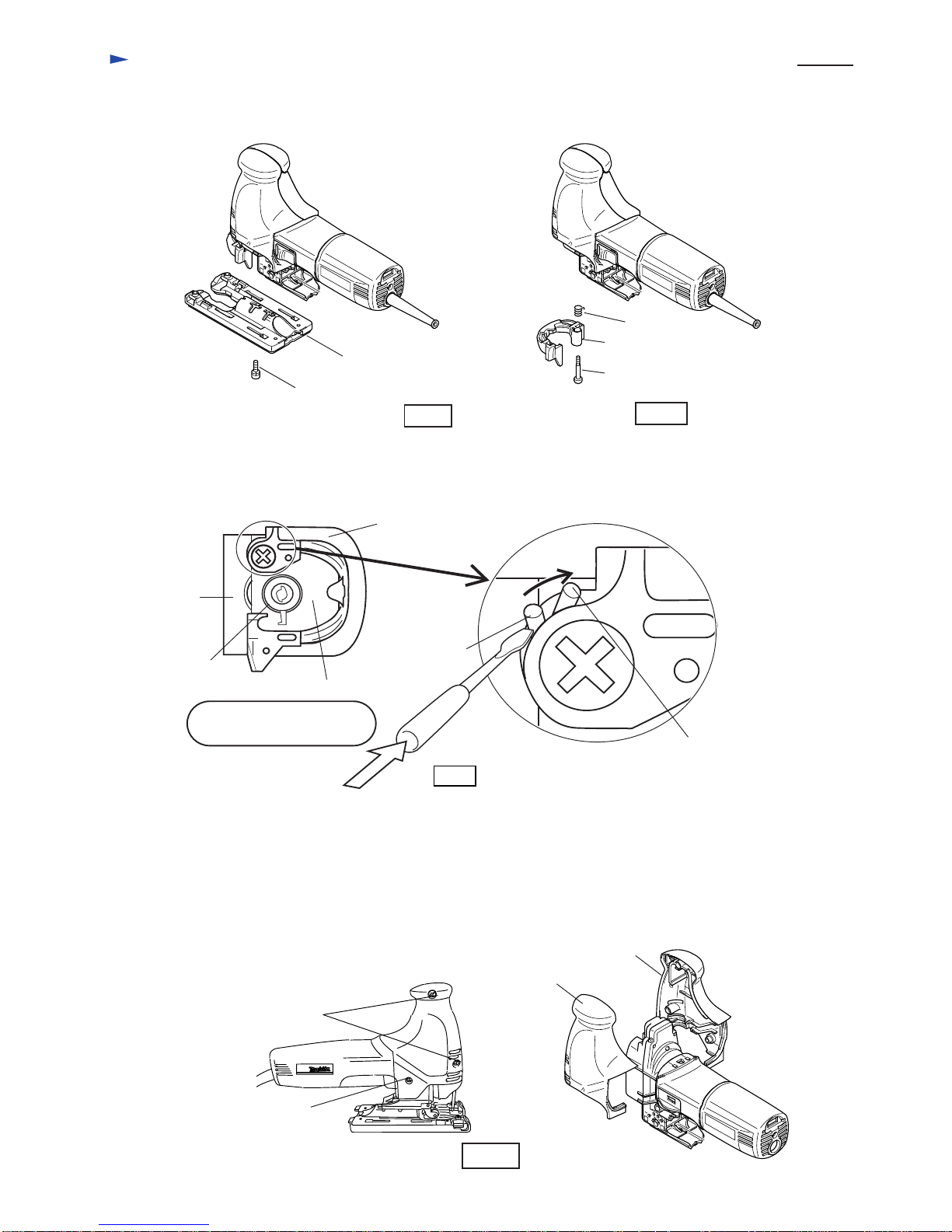

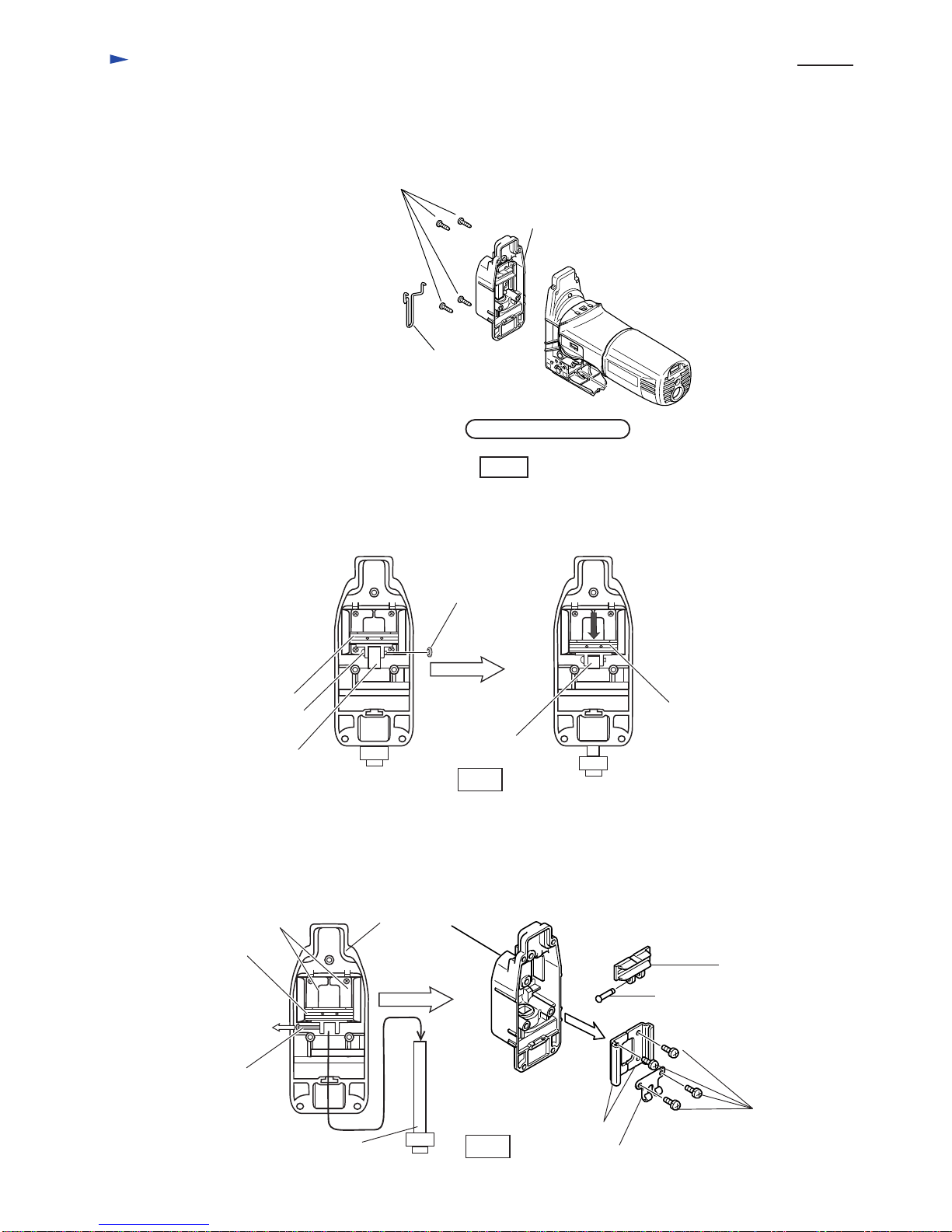

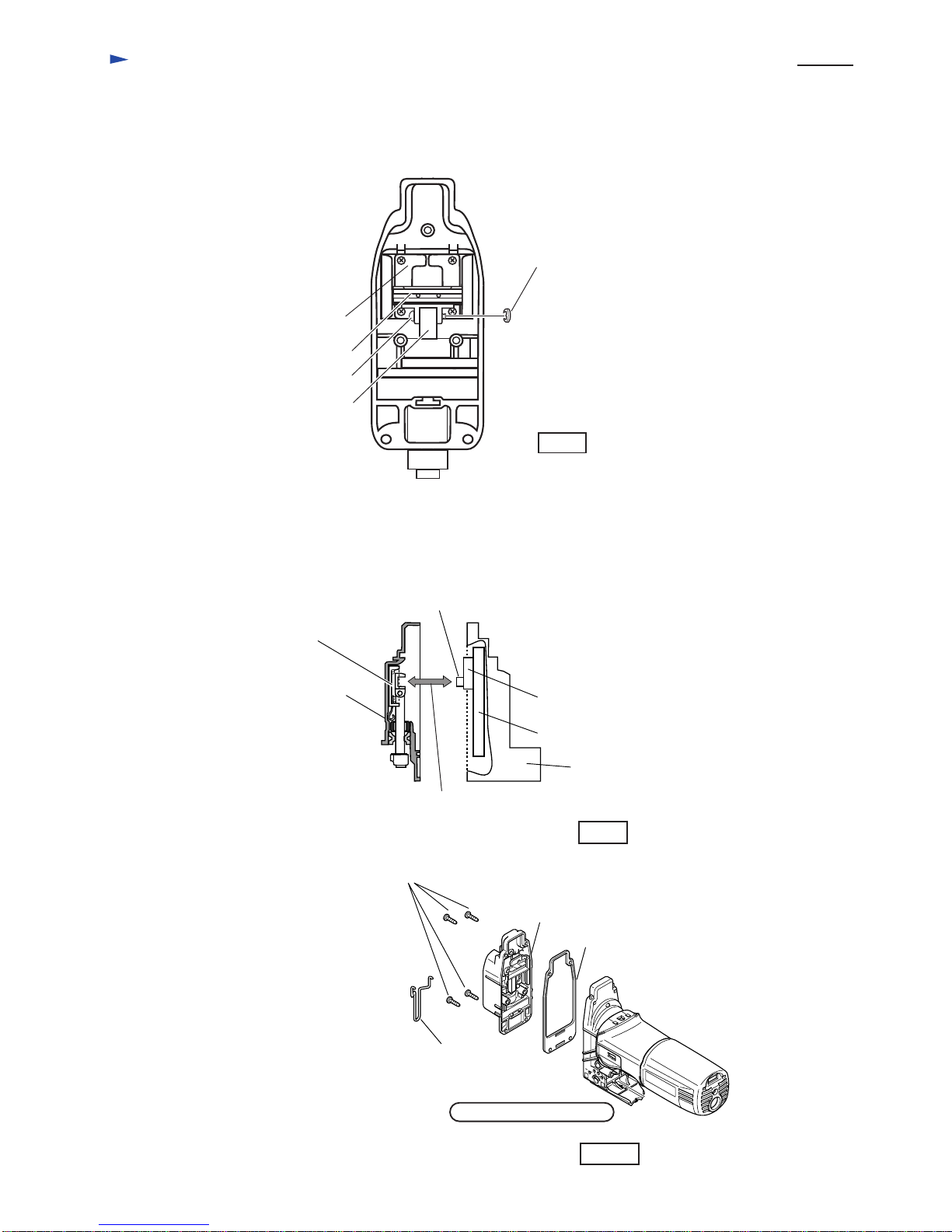

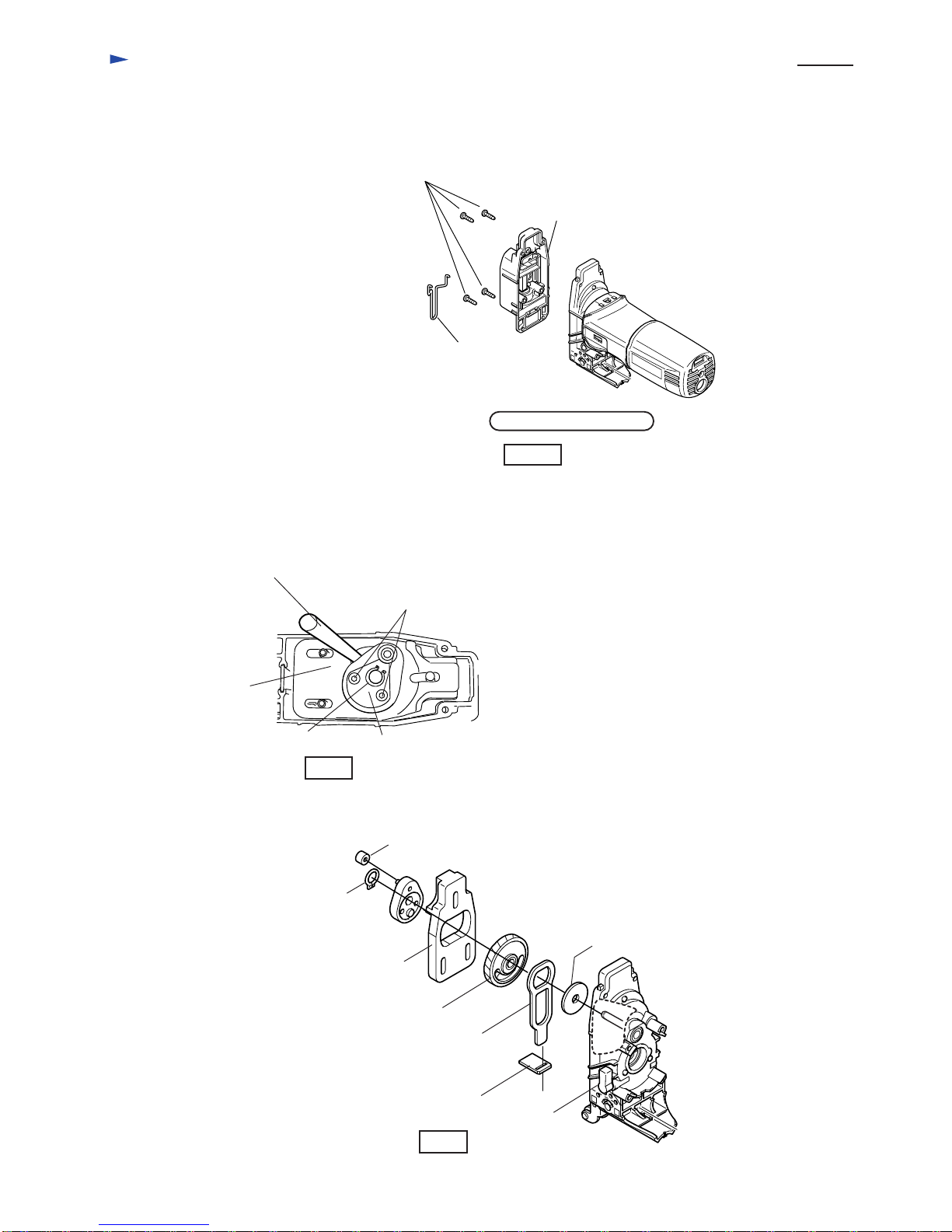

* New tool less blade change system

* Incredibly low vibration and noise level

* Built-in electronic for keeping constant speed

and soft start

* Pre-setting speed dial for optional speed setting

In addition to the above features, Model 4341FCT

is equipped with LED job light for easy tracing your cutting line.

* With attaching jig saw

blade No. B-16L(optoinal accessory),

800 - 2,800

26 ( 1 )

10 (3/8)

20 (25/32)

* 135 (5-5/16)

Strokes per min. : spm.= min.-1

Length of Stroke : mm ( " )

Blade

shank

Max.cutting

capacities

: mm (")

Wood

Mild Steel

Aluminum

2.4 (5.3)

2.5 (8.2)

by double insulation

Net weight : Kg (lbs.)

Cord length : m (ft)

Speed control

Soft start

Variable speed

Protection from electric shock

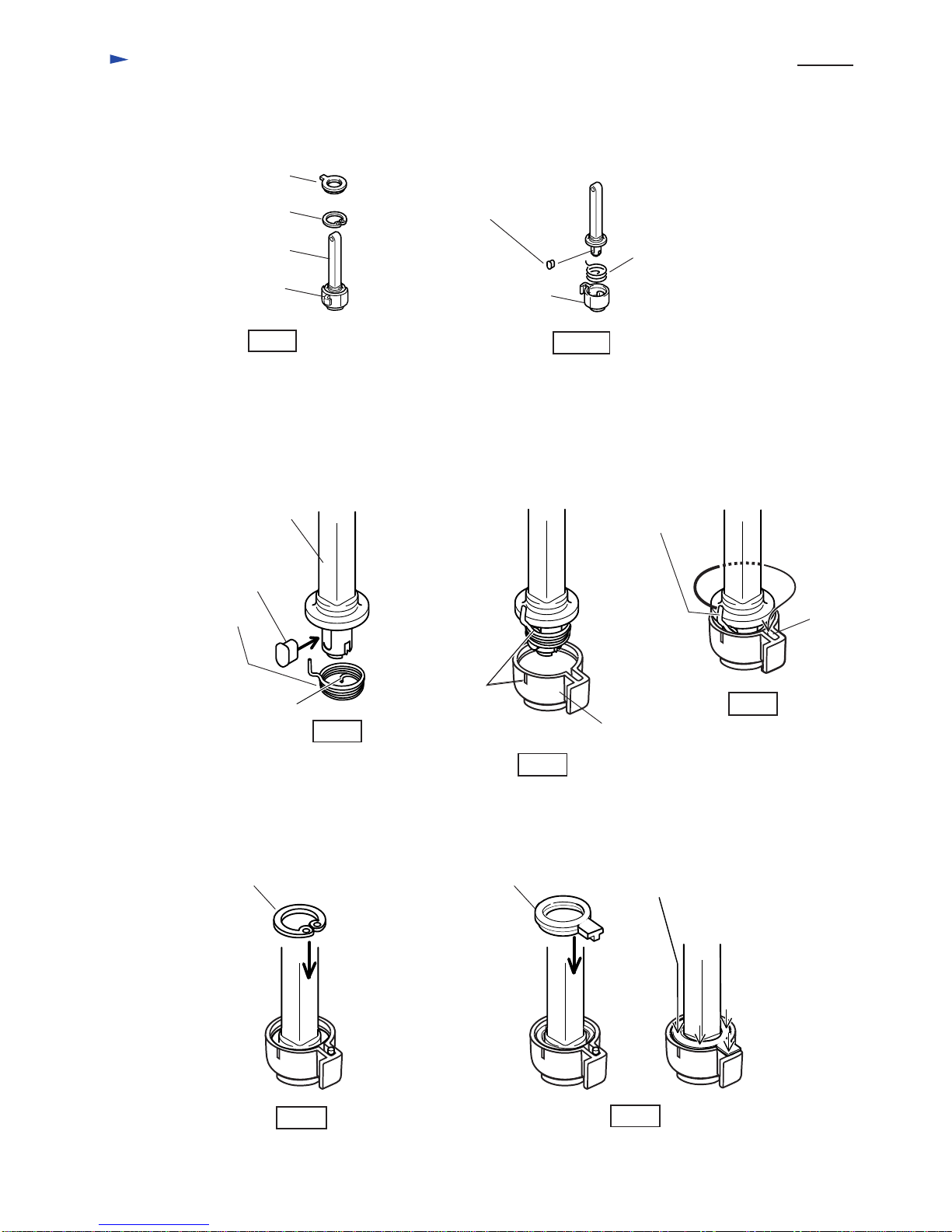

MAKITA Type

BOSCH Type

Orbital action of blade Yes / 3 stages

Yes

Electronic

Yes

Yes

Yes