10

• Be sure to move the tool forward in a straight line

gently. Forcing or twisting the tool will result in

overheating the motor and dangerous kickback,

possibly causing severe injury.

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery.

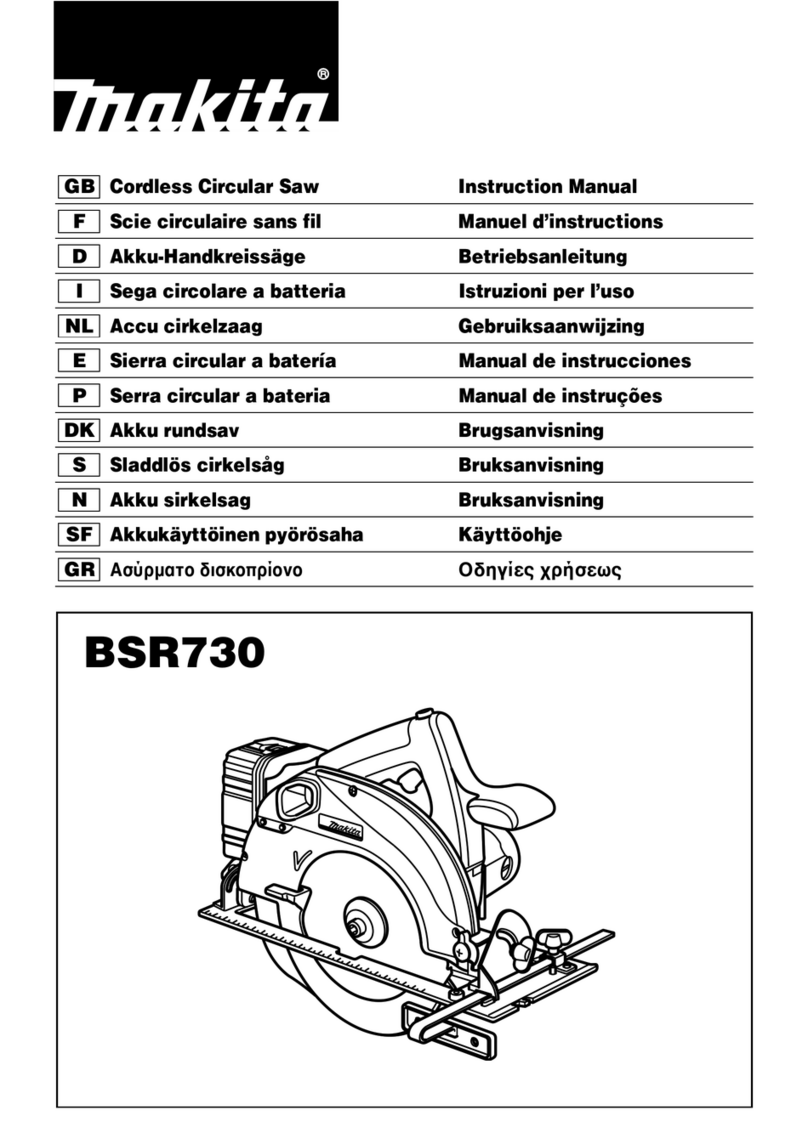

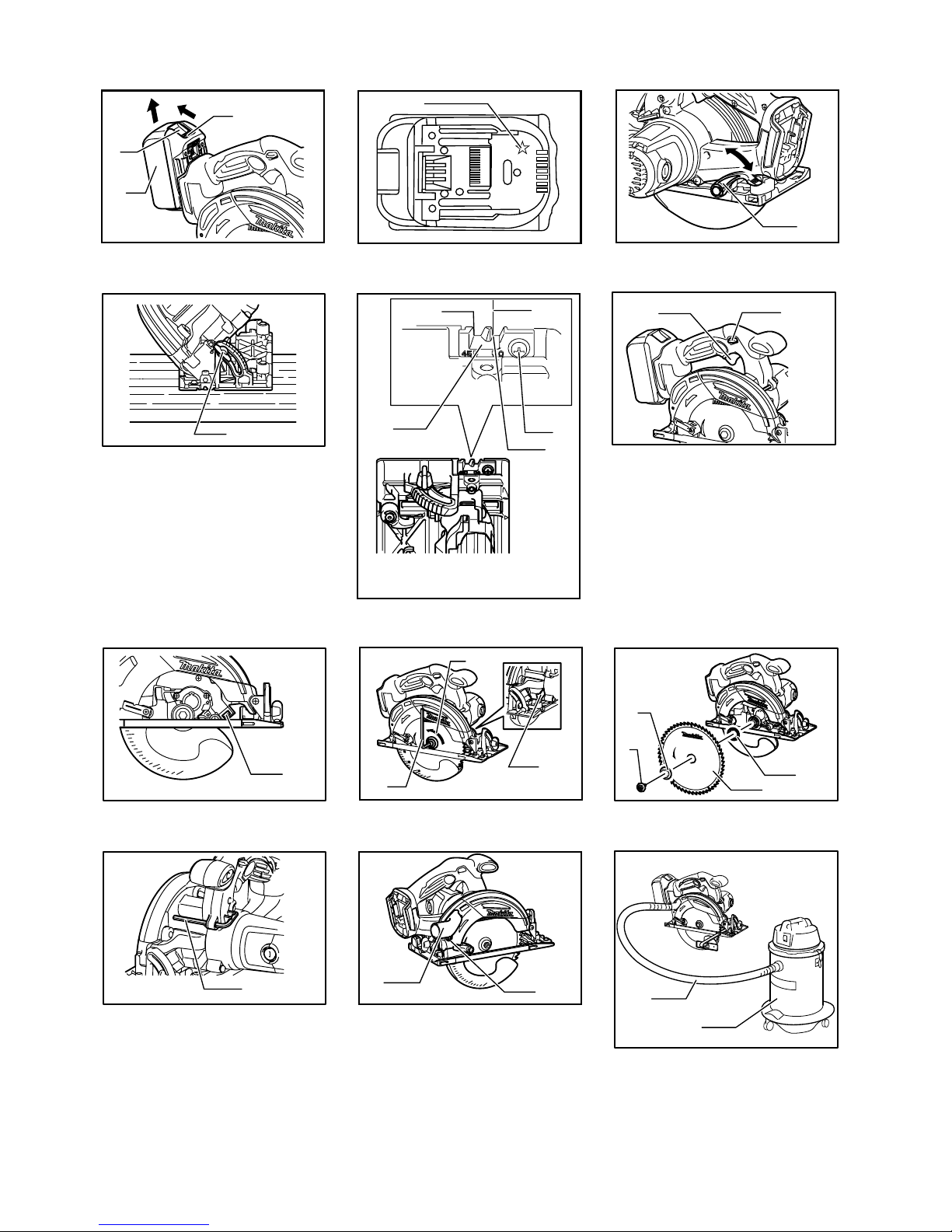

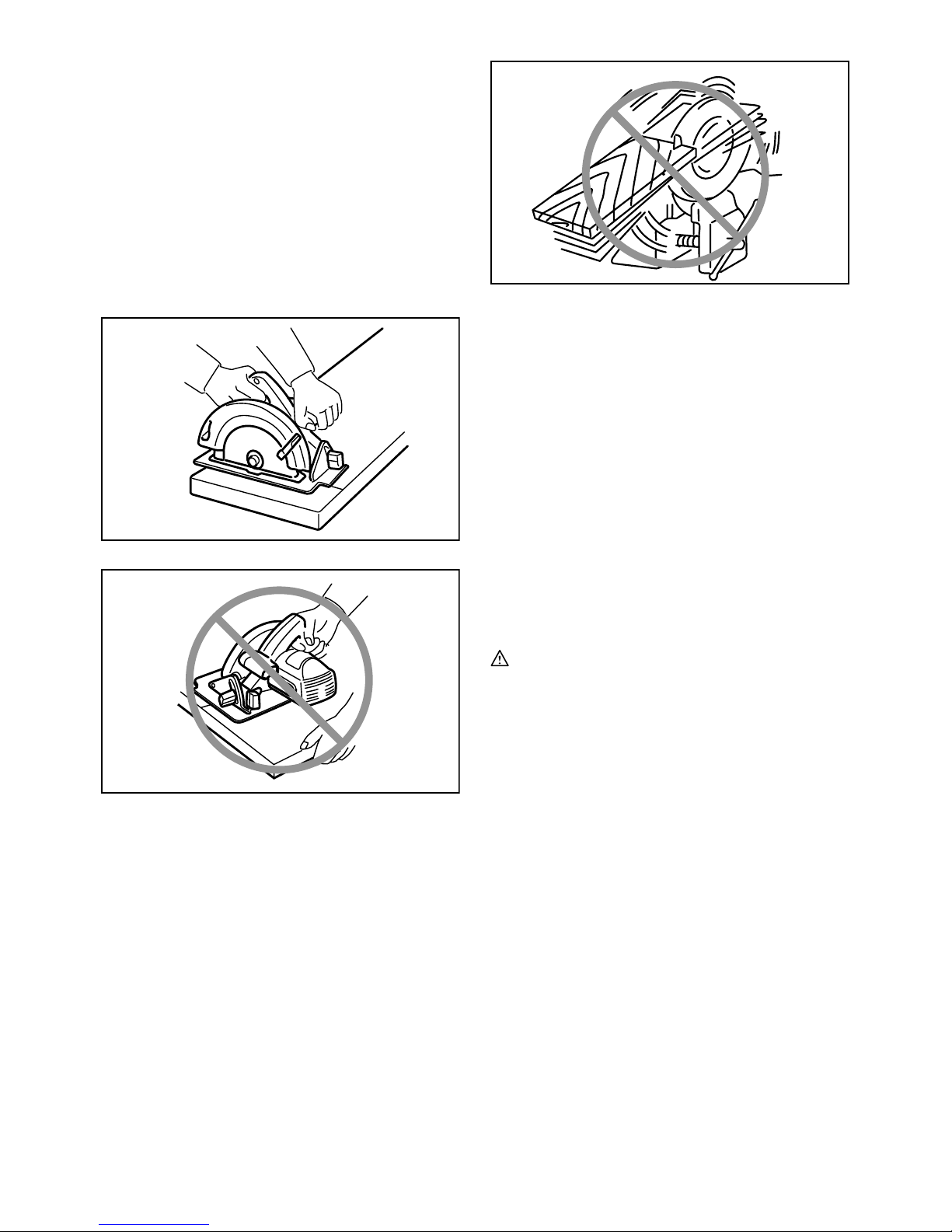

Fig.13

Hold the tool firmly. The tool is provided with both a front

grip and rear handle. Use both to best grasp the tool. If

both hands are holding saw, they cannot be cut by the

blade. Set the base on the workpiece to be cut without

the blade making any contact. Then turn the tool on and

wait until the blade attains full speed. Now simply move

the tool forward over the workpiece surface, keeping it

flat and advancing smoothly until the sawing is

completed.

To get clean cuts, keep your sawing line straight and your

speed of advance uniform. If the cut fails to properly

follow your intended cut line, do not attempt to turn or

force the tool back to the cut line. Doing so may bind the

blade and lead to dangerous kickback and possible

serious injury. Release switch, wait for blade to stop and

then withdraw tool. Realign tool on new cut line, and start

cut again. Attempt to avoid positioning which exposes

operator to chips and wood dust being ejected from saw.

Use eye protection to help avoid injury.

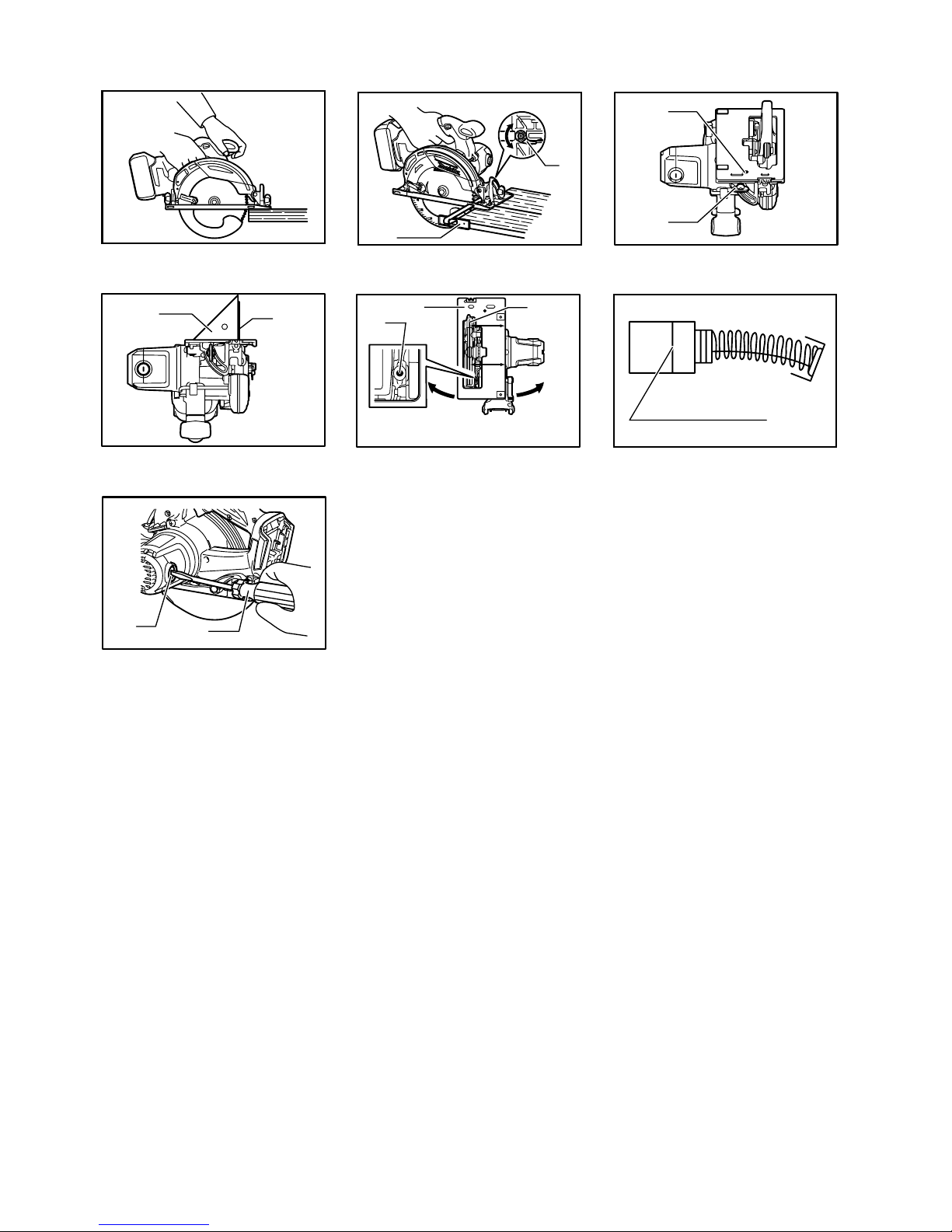

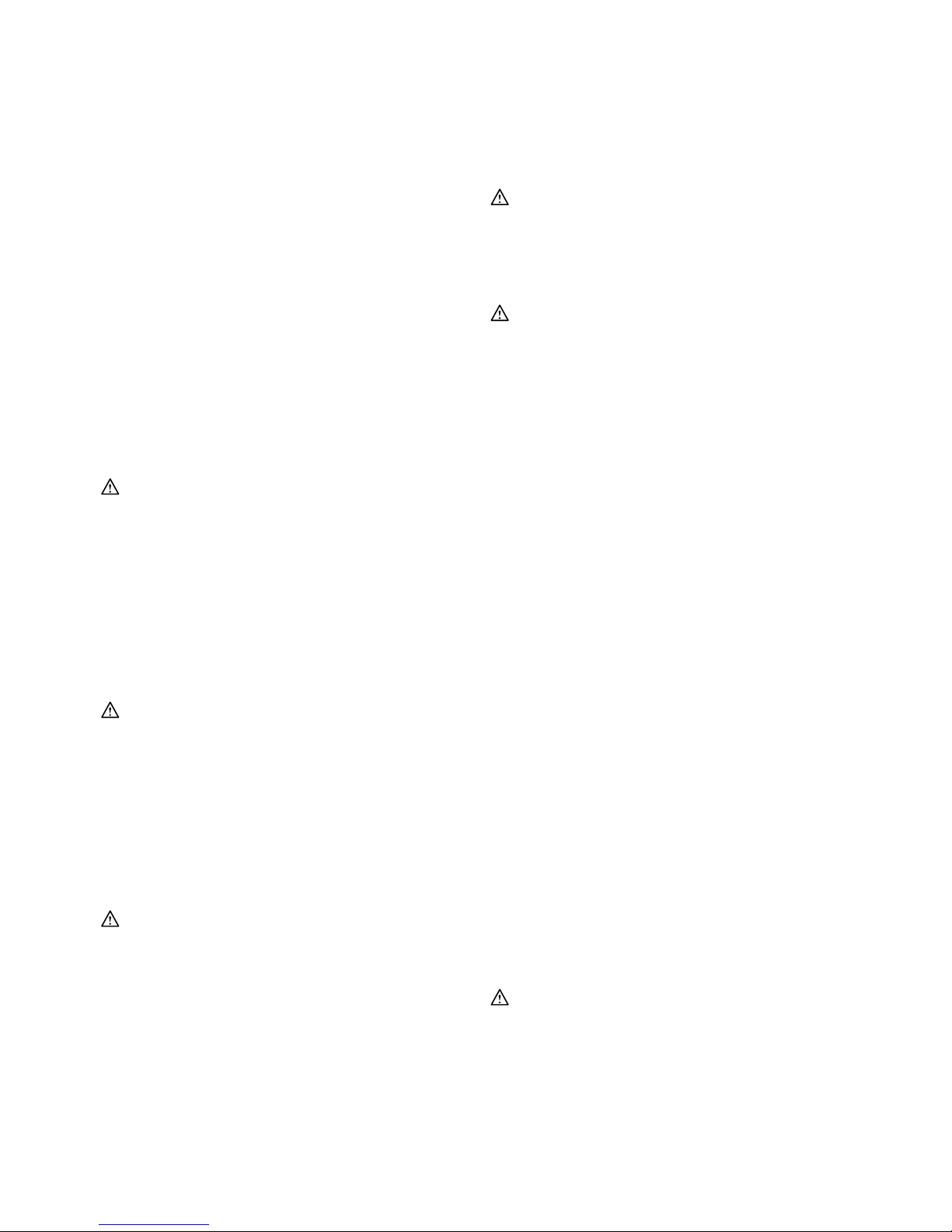

Rip fence (Guide rule)

Fig.14

The handy rip fence allows you to do extra-accurate

straight cuts. Simply slide the rip fence up snugly against

the side of the workpiece and secure it in position with

the clamp lever on the front of the base. It also makes

repeated cuts of uniform width possible.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before attempting to

perform inspection or maintenance.

• Never use gasoline, benzine, thinner, alcohol or

the like. Discoloration, deformation or cracks may

result.

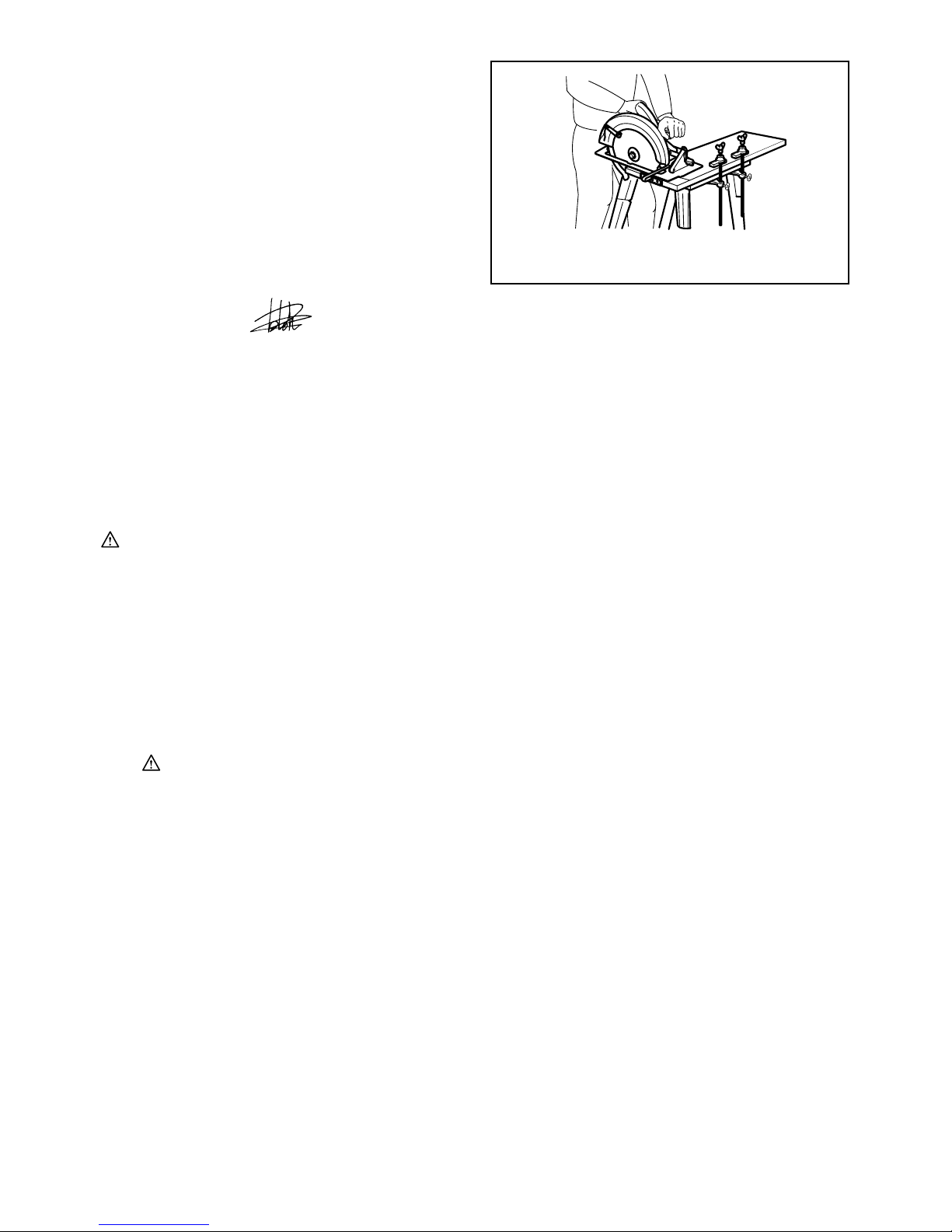

Adjusting for accuracy of 90°cut (vertical cut)

Fig.15

Fig.16

This adjustment has been made at the factory. But if it is

off, adjust the adjusting screw with a hex wrench while

inspecting 90°the blade with the base using a triangular

rule or square rule, etc.

Adjusting for parallelism

Fig.17

The parallelism between the blade and the base has

been factory adjusted. But if it is off, you can adjust it as

the following procedure.

Make sure all levers and screws are tightened. Slightly

loosen the screw as illustrated. While opening the lower

guard, move the rear of base so that the distance A and

B are equal. After adjusting, tighten the screw. Make a

test cut to get a correct parallelism.

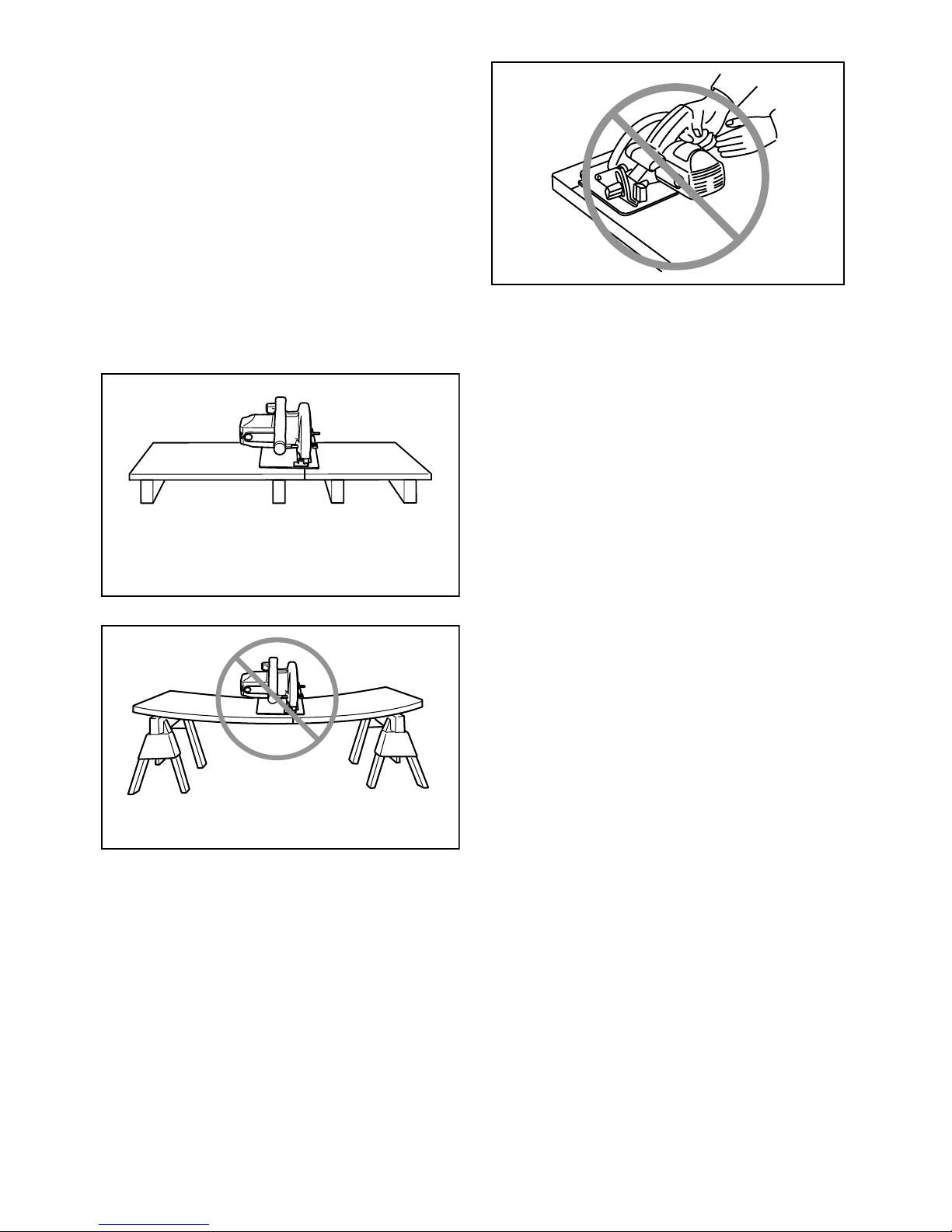

Replacing carbon brushes

Fig.18

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Fig.19

Use a screwdriver to remove the brush holder caps.

Take out the worn carbon brushes, insert the new ones

and secure the brush holder caps.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers,

always using Makita replacement parts.

OPTIONAL ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Saw blades

• Rip fence (Guide rule)

• Hex wrench 5

• Dust nozzle

• Guide rail adapter

• Guide rail

• Various type of Makita genuine batteries and

chargers

NOTE:

• Some items in the list may be included in the tool

package as standard accessories. They may differ

from country to country.