Models BTM40, BTM50 are

DC multi tools to compete with the Competitor F’s

Models F1-AC/ F2-AC.

These models have been developed for commercial use,

and their high performance will satisfy professional users

accustomed to AC multi tools.

These products are powered by the following Li-ion batteries:

BTM40 by BL1415/ BL1430 (14.4V-1.3/ 3.0Ah)

BTM50 by BL1815/ BL1830 (18V-1.3*2/ 3.0Ah)

BTM40, BTM50

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

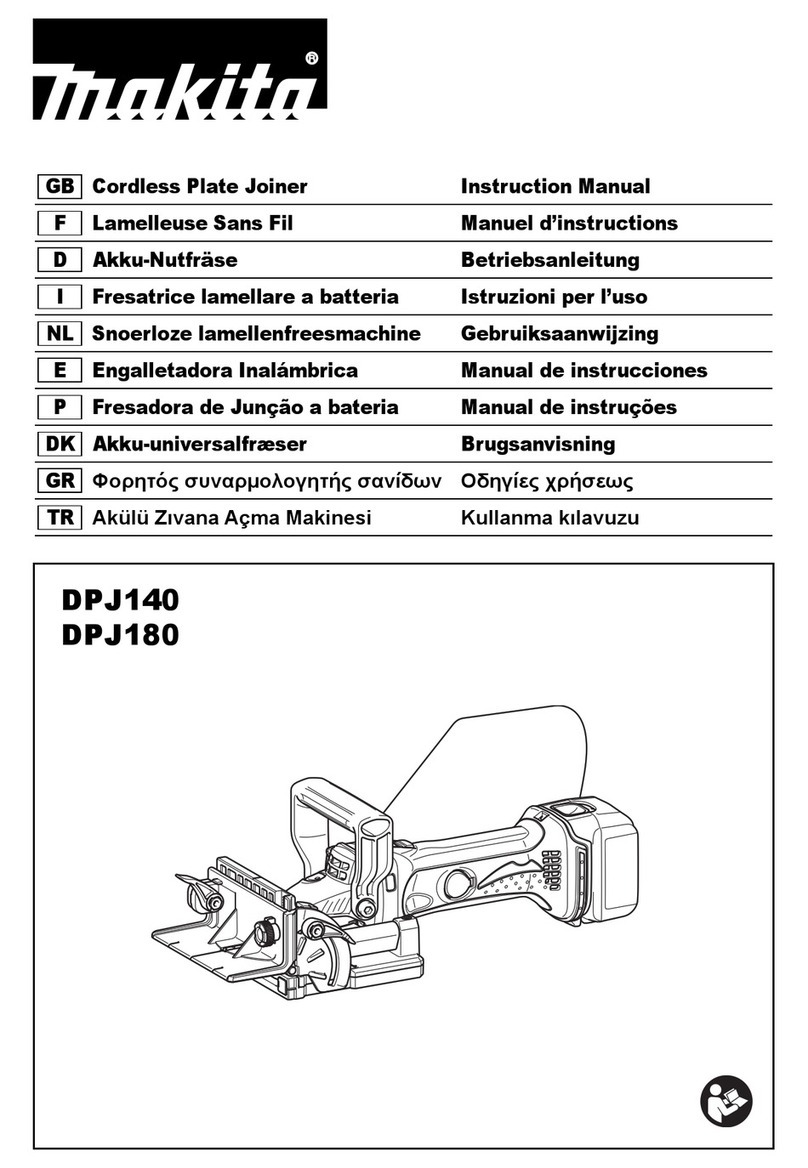

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 307 (12-1/4)*3/ 324 (12-3/4)*4

80 (3-1/8)

122 (4-13/16)104 (4-1/8)

BTM50BTM40

DC Multi tools

Standard equipment

Note: The standard equipment for the tool shown above may vary by country.

Oscillating multi tool accessories

[equivalent to the Competitor B’s B-system] ............................... 1

Adapter A ....................................................................................... 1 (for some countries only)

Adapter C ....................................................................................... 1 (for some countries only)

Tool box (for storing oscillating multi tool accessories) ................ 1 (for some countries only)

Hex wrench ..................................................................................... 1

Dust attachment set ......................................................................... 1 (for some countries only)

Plastic carrying case or Tool bag .................................................... 1 (for some countries only)

Optional accessories

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

1.7 (3.8)*7, 1.8 (4.0)*8/

1.9 (4.2)*7, 2.0 (4.4)*8

1.8 (3.9)*7, 1.9 (4.1)*8/

2.0 (4.4)*7, 2.1 (4.6)*8

YesVariable speed control by dial

Anti-restart function

Oscillations per minute: opm=minˉ¹

Oscillating multi tool accessories

*5: for some countries only

*6: for North and Central American countries

*7: with Battery and Vacuum attachment, without Sanding pad

*8: with Battery, Sanding pad, and Vacuum attachment

6,000 - 20,000

Oscillation angle, left/right: degree [°] 1.6 (3.2 total)

Makita oscillating multi tool accessories

equivalent to the Competitor B’s B-system

Soft start Yes

Electronic

control

Yes

Oscillating multi tool accessories

[equivalent to the Competitor B’s B-system]

Tool box (for storing oscillating multi tool accessories)

Dust attachment set

Triangular abrasive papers (Hook & loop type)

Adapter A

Adapter C

Li-ion battery BL1415 (for BTM040)

Li-ion battery BL1430 (for BTM040)

Li-ion battery BL1815 (for BTM050)

Li-ion battery BL1830 (for BTM050)

Fast charger DC18RA

(for USA, Canada, Guam, Panama, Colombia, Mexico)

Fast charger DC18RC

(for all countries except the countries above)

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

PRODUCT

P 1/10

These new products are available in several variations

with various accessories by country.

W

L

H

BTM40*4

BTM50*4

Specification Model

Battery

Cell

Voltage: V

Capacity: Ah

Li-ion

14.4 18

BTM40 BTM50

1.3 (1.5*5)/ 3.01.3/ 3.0

Max output: W 300280

Energy capacity: Ah 24 (27*5)/ 5419/ 44

15/ 22 with DC18RC (DC18RA*6)Charging time (approx.): min.

YesLED Job light

TECHNICAL INFORMATION

*3 with 1.3Ah Li-ion battery of BL1415 or BL1815

*4 with 3.0Ah Li-ion battery of BL1430 or BL1830

*2 1.5Ah for some countries

OFFICIAL USE

for ASC & Sales Shop