P 2/17

[2] LUBRICATION

Apply the following lubricants to protect parts and product from unusual abrasion:

*Makita grease N.No.1 to the portions designated with black triangle

*Makita grease R.No.00 to the portions designated with gray triangle

*Makita grease N.No.2 to the portions designated with white triangle

[1] NECESSARY REPAIRING TOOLS

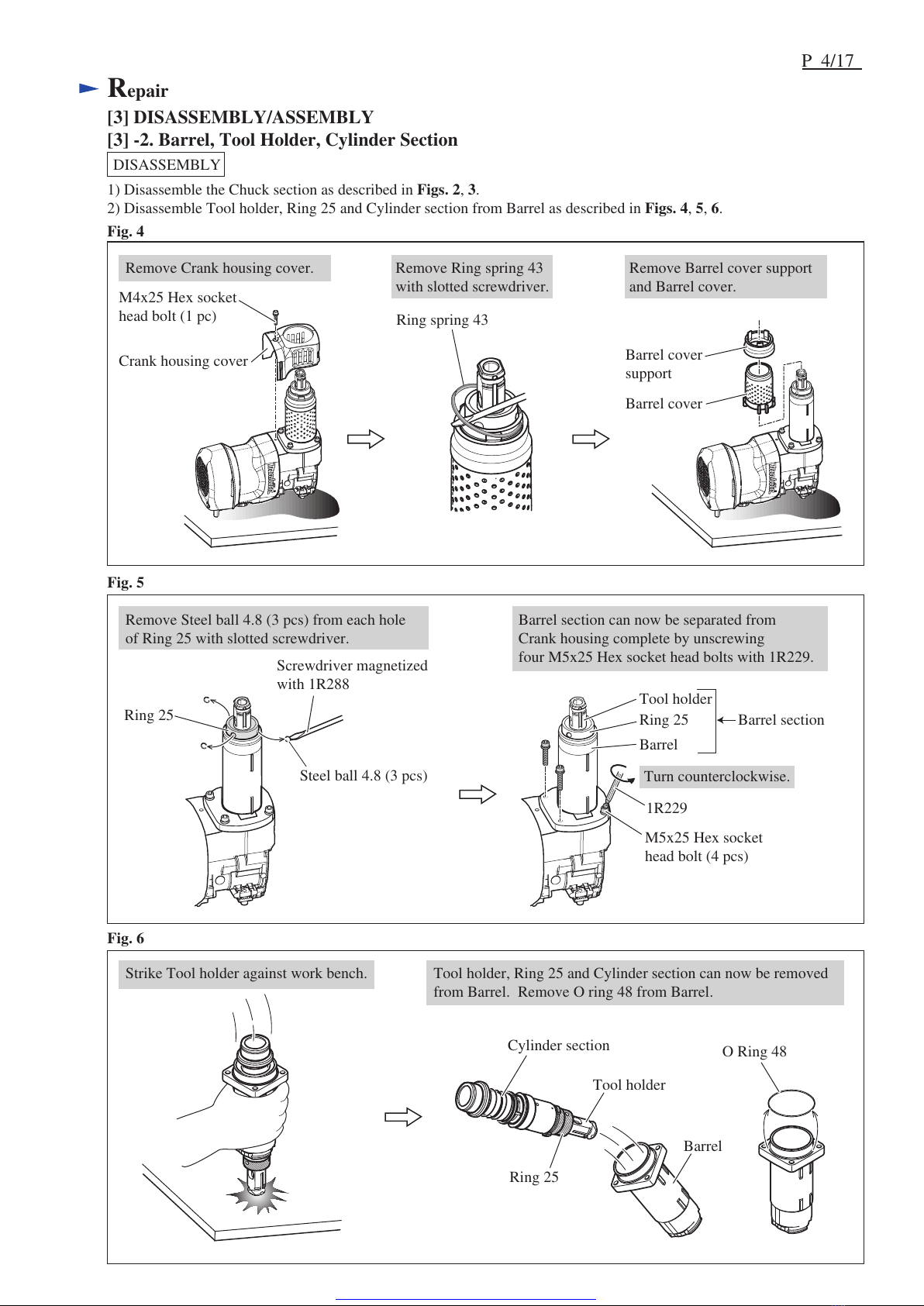

CAUTION: Remove the bits from the machine for safety before repair/maintenance

in accordance with the instruction manual!

Fig. 1

Repair

DescriptionCode No. Use for

Item No. Description Portion to lubricate

1R003

1R022

1R023

1R029

1R212

1R228

1R229

1R258

1R288

Retaining ring pliers ST-2N

Bearing plate

Pipe ring

Bearing setting pipe 23-15.2

Tip for retaining ring pliers

1/4" Hex shank bit for M4

1/4" Hex shank bit for M5

V Block

Screwdriver magnetizer

Removing/mounting Ring spring

Stabilizing Bearing box when removing Ball bearing 6002LLU

Stabilizing Crank housing complete when removing Armature

Removing Oil seal 15 and Ball bearing 6002LLU from Bearing box

Removing/mounting Ring spring (for modular use with 1R003)

1R225 Bearing extractor Removing Armature and Ball bearing 6001DDW from Crank housing comp.

Removing M4x25 Hex socket head bolt from Crank housing cover

Removing M5x25 Hex socket head bolt from Barrel

Stabilizing Bearing box when removing Helical gear 36

Magnetizing Screwdriver when removing Steel balls and Pins

Ring 25 Impact bolt

Tool holder

Compression spring 32

23 27

7

Striker

30

Piston

Connecting rod

38

68

37

27 O Ring 12 Whole portion

Cylinder Inside surface that Piston and Striker contacts

Whole portion

30

7 Steel ball 4.8 (3 pcs) Whole portion

23 Steel Ball 7.0 (2 pcs) Whole portion

37 O Ring 18 on Striker

O Ring 18 on Piston Whole portion

38

32

32 Ring 29 Inside periphery that contacts 30 Cylinder

3g

17g

4g

39 Pin 7 Cylindrical surface that contacts Connecting rod

Flat washer 22

Crank housing complete Crank room

Whole portion for smooth rotation

of Helical gear 36

58 59

61

68 Armature Gear portion for smooth rotation

of Helical gear 36

39

AmountLubricant

Makita grease

N.No.2

Makita grease

N.No.1

Makita grease

R.No.00

a little

a little

a little

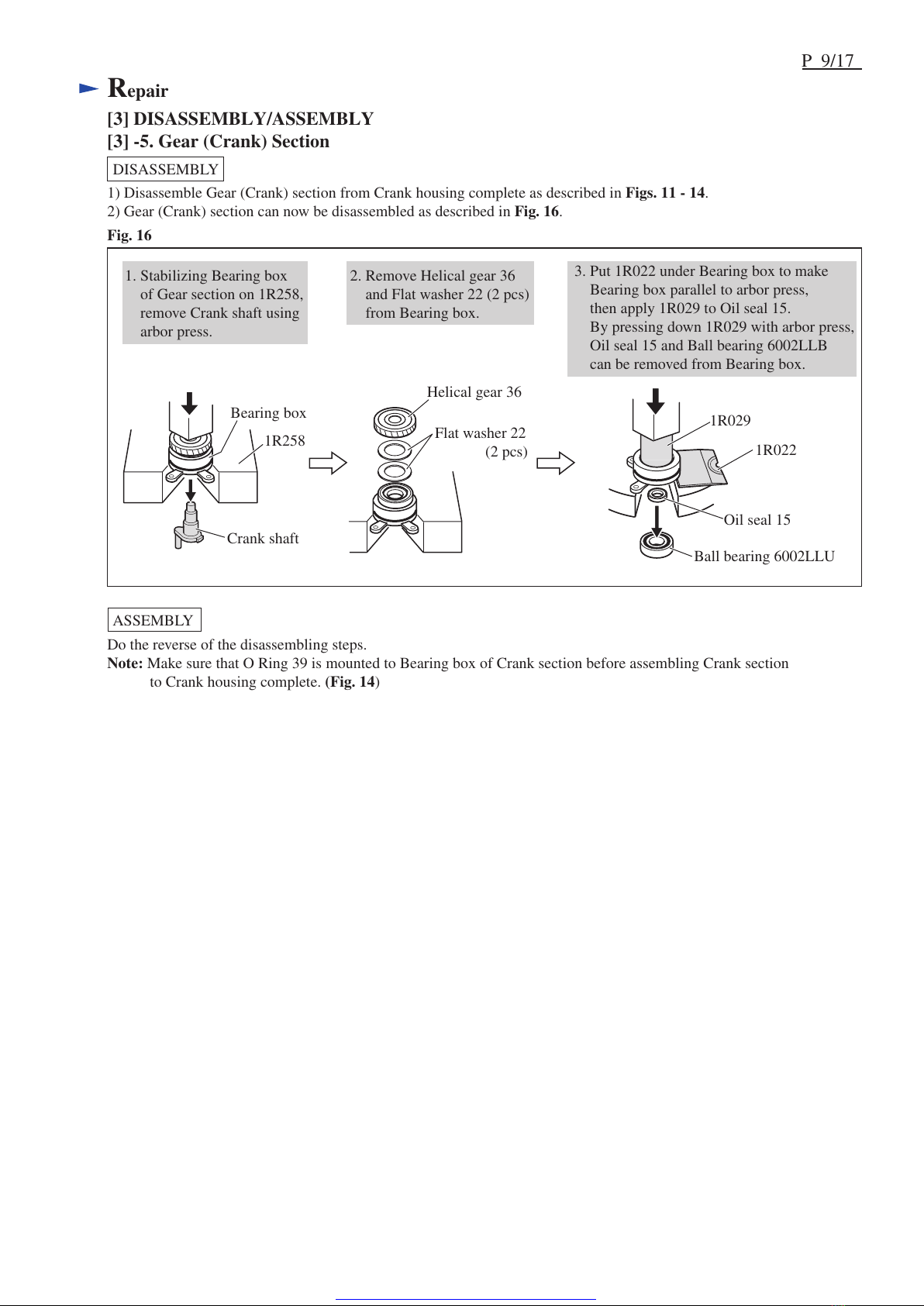

Crank shaft

Bearing box

Helical gear 36

58

59

61

23

a little