4

Table of Contents

Table of Contents ...................................................................................................................................................................4-5

Dual Loop Overview ..............................................................................................................................................................6-8

Component Parts and Assembly Hardware plus Optional Equipment.....................................................................9-10

MT-3405D System Layout with Liquid Branch on Loop 2............................................................................................... 11

MT-3405D Wiring with Liquid Branch on Loop 2 ............................................................................................................. 12

MT-3405D System Layout with Layout with NH3 on Loop 2 ......................................................................................... 13

MT-3405D Wiring with NH3 Branch on Loop 2 ................................................................................................................. 14

MT-3405D Bypass Configuration ......................................................................................................................................... 15

MT-3405D In-Line Configuration ......................................................................................................................................... 16

Installation.......................................................................................................................................................................... 17-23

Required Tools.......................................................................................................................................................................................... 17

Mounting the Display Console...........................................................................................................................................................17

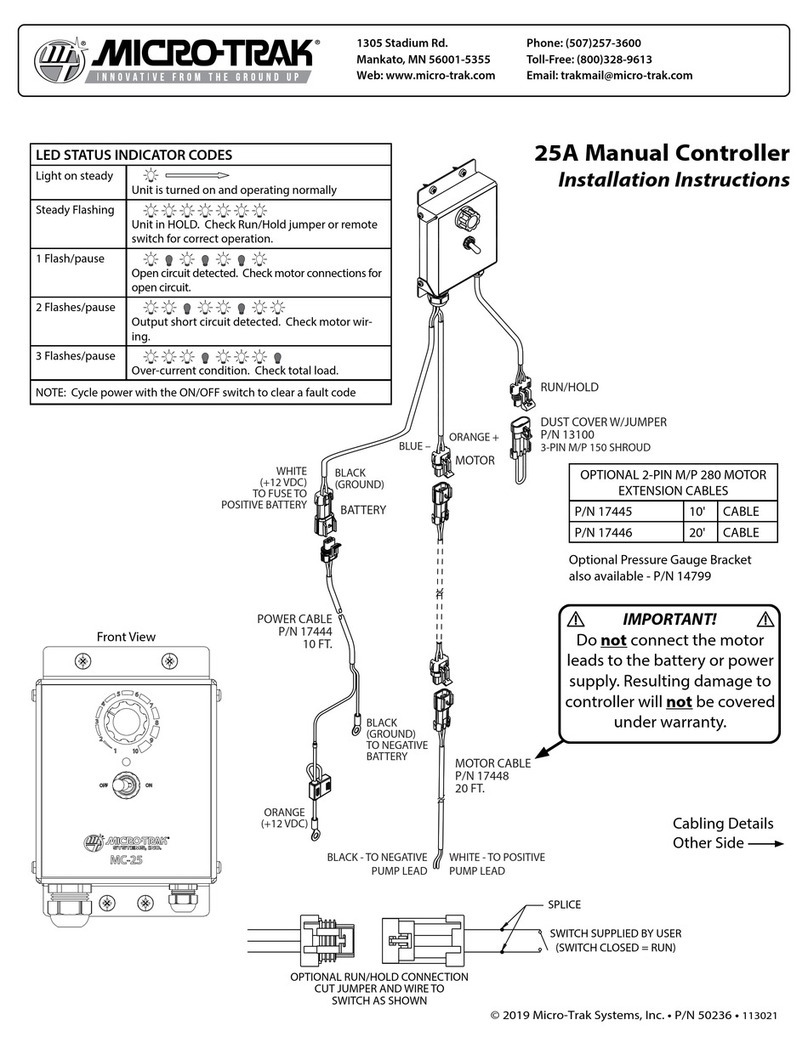

Electrical Installation ..............................................................................................................................................................................17

Speed Sensor Installation...............................................................................................................................................................18-19

Magnets..............................................................................................................................................................................................18

Attaching Magnets......................................................................................................................................................................... 18

Attaching the Speed Sensor................................................................................................................................................................19

Connecting the Speed Sensor Cable ...............................................................................................................................................19

Speed Sensor Options ...........................................................................................................................................................................19

Remote Run/Hold (Ch1 only)..............................................................................................................................................................20

Mounting and Plumbing Flowmeter ...............................................................................................................................................21

Installing Flow Sensor Cable ...............................................................................................................................................................21

Manual Pressure Relief Valve ..............................................................................................................................................................22

Range Adjust Valve................................................................................................................................................................................. 22

Servo, Throttling Valves ........................................................................................................................................................................ 22

Electric Relief Valve (Ch1 Only)...........................................................................................................................................................23

Boom Connections .................................................................................................................................................................................23

Care and Maintenance of your MT-3405D ......................................................................................................................... 23

Console Functions............................................................................................................................................................. 24-25

Calibration .......................................................................................................................................................................... 26-30

English/Metric Selection....................................................................................................................................................................... 26

Entering Calibration Values ...........................................................................................................................................................27-29

Ch1/Ch2 Cal Selection ..................................................................................................................................................................27

Calibration Factors (Flow Cal, Min Flow, Target Rate, Width, Inline/Bypass.......................................................27-28

Determining the Speed Cal.........................................................................................................................................................29

Radar or GPS Speed Sensor Calibration .................................................................................................................................29

Drive Shaft Speed Sensor Calibration .....................................................................................................................................29

Exiting Calibration..........................................................................................................................................................................28

Factory-loaded Calibration Values (Channels 1 and 2).....................................................................................................30

Special Calibration ............................................................................................................................................................ 31-33

Operation............................................................................................................................................................................ 34-39

Manual Operation (Channels 1 and 2)............................................................................................................................................. 34

Automatic Operation (Channels 1 and 2).................................................................................................................................35-36

Clearing System Counters....................................................................................................................................................................36

Resetting System Counters..................................................................................................................................................................37

Pre-field System Checkout - Bypass Servo.....................................................................................................................................38

Pre-field System Checkout - Inline Servo .......................................................................................................................................39

Entering Target Application Test Speed into Console......................................................................................................39

Troubleshooting........................................................................................................................................................................................40-44

Messages/Warnings................................................................................................................................................................................40

Troubleshooting (general, such as speed is erratic, area count is erratic, display doesn’t make sense, etc. .......41

Checking Individual Components.....................................................................................................................................................42

Console Inputs..........................................................................................................................................................................................43

Plumbing Troubleshooting Chart .....................................................................................................................................................44