4

Table of Contents

Warranty...................................................................................................................................................................................... 3

Table of Contents ...................................................................................................................................................................4-5

Introduction ............................................................................................................................................................................... 6

Basic Overview of Typical Installation .................................................................................................................................. 7

Component Parts and Assembly Hardware......................................................................................................................8-9

Installation.......................................................................................................................................................................... 10-20

Required Tools..........................................................................................................................................................................................10

Mounting the Display Console...........................................................................................................................................................10

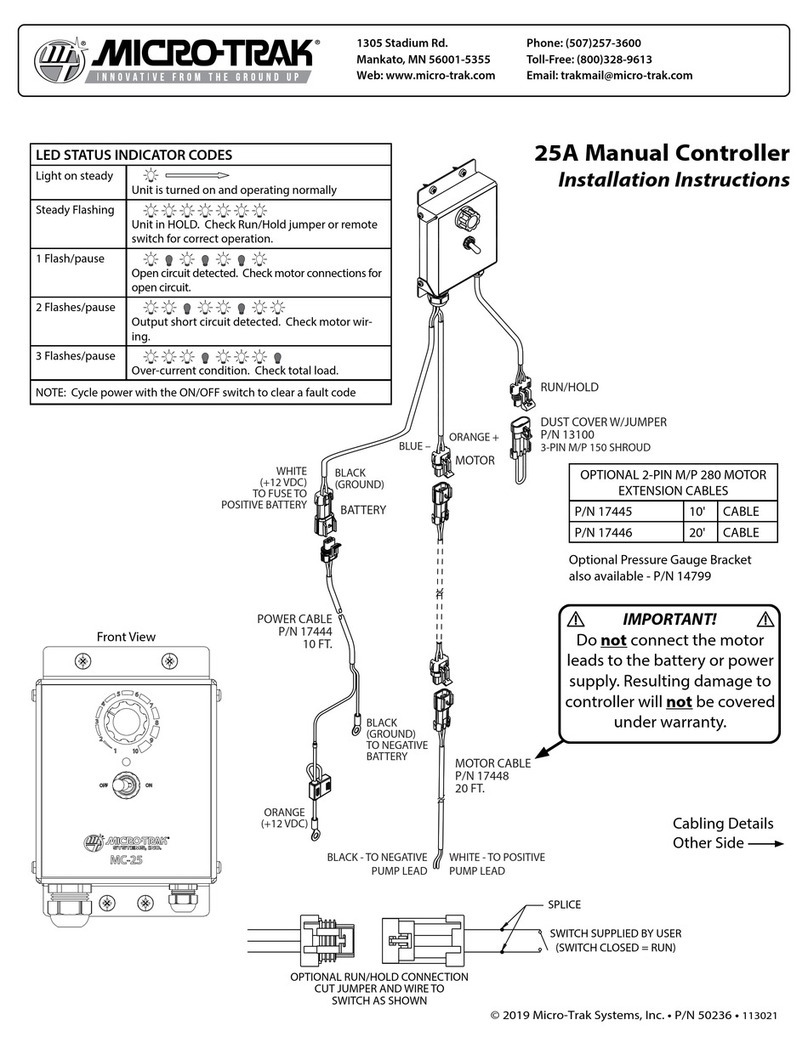

Electrical Installation ..............................................................................................................................................................................10

Speed Sensor Installation...............................................................................................................................................................11-12

Magnets..............................................................................................................................................................................................11

Attaching Magnets......................................................................................................................................................................... 11

Attaching Speed Sensor .......................................................................................................................................................................12

Connecting the Speed Sensor Cable ...............................................................................................................................................12

Connecting the Run/Hold Sensor Cable.........................................................................................................................................13

Speed Sensor Options ...........................................................................................................................................................................13

Mounting and Plumbing Flowmeter ...............................................................................................................................................14

Installing Flow Sensor Cable ...............................................................................................................................................................14

Pressure Relief Valve...............................................................................................................................................................................15

Range Adjust Valve.................................................................................................................................................................................15

Installing Pressure Sensor ....................................................................................................................................................................15

Servo, Throttling Valves ........................................................................................................................................................................ 16

Electric Relief Valve................................................................................................................................................................................. 16

Boom Shut-off Valves.............................................................................................................................................................................17

Plumbing Overview Diagram..............................................................................................................................................................18

Valve Diagrams.........................................................................................................................................................................................19

Wiring Diagram........................................................................................................................................................................................20

Console Functions................................................................................................................................................................... 21

Calibration .......................................................................................................................................................................... 22-31

Introduction to Calibration..................................................................................................................................................................22

“Special” Calibration.........................................................................................................................................................................22-24

Entering “Special” Calibration Values................................................................................................................................22-23

Units of Measure, Servo Type, Servo Polarity................................................................................................................23

Boom Shut-Off Valve Type, Tank Alarm Set Point, Tank Size ..................................................................................24

Exiting “Special” Calibration ................................................................................................................................................24

Special Factory-loaded Calibration Values.....................................................................................................................24

Standard Calibration ........................................................................................................................................................................25-31

Entering Standard Calibration Values...............................................................................................................................25-28

Target Rate, Adjust Rate........................................................................................................................................................25

Boom Width, Setting Individual Boom Width, Banding Application Calibration ............................................ 26

Min Flow......................................................................................................................................................................................26

Flowmeter, Distance...............................................................................................................................................................27

Determining Wheel Circumference ..................................................................................................................................27

Pressure Offset ..........................................................................................................................................................................28

Fine-tuning Speed/Distance Calibration ...............................................................................................................................29

Fine-tuning Flowmeter Calibration..........................................................................................................................................30

Standard Factory-loaded Calibration......................................................................................................................................31

Exiting Standard Calibration.......................................................................................................................................................31

Test Speed.........................................................................................................................................................................................31

Pre-field System Checkout .................................................................................................................................................... 32