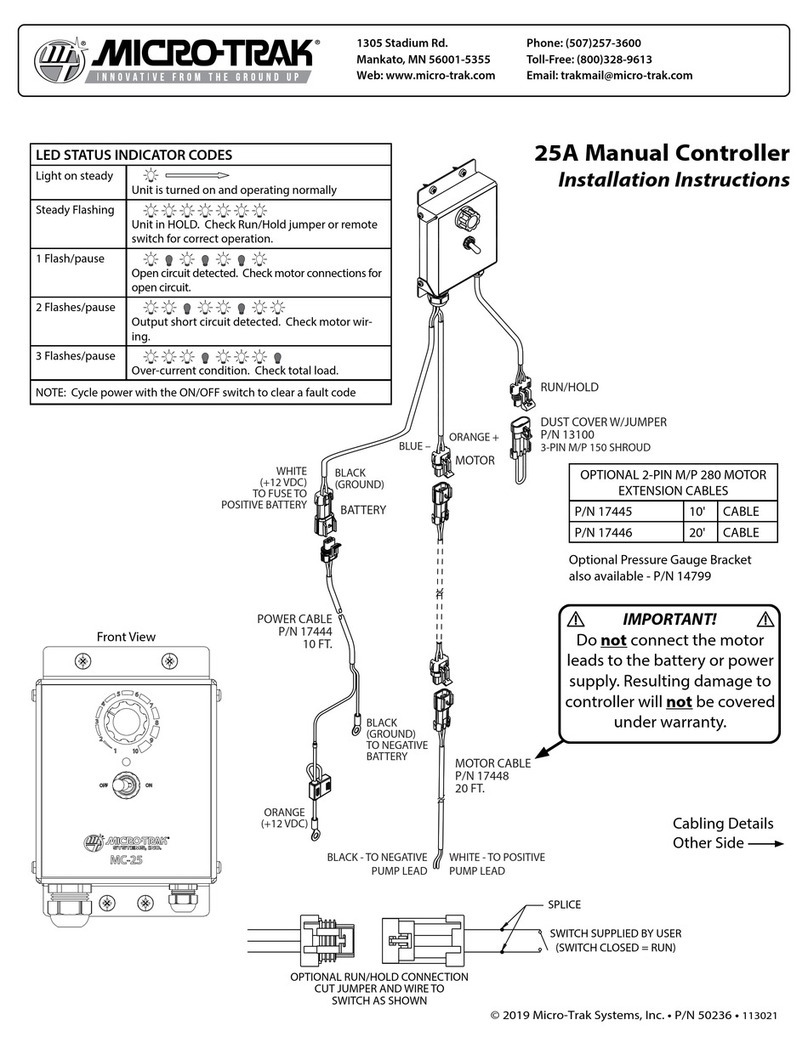

Drive Shaft Speed Sensor Calibration

NOTE: If you have mounted the magnetic speed sensor on

a wheel, skip this step and go on to Fine Tuning Speed/

Distance Calibration Values.

Because of the difference in wheel-to-drive shaft ratios, it is

difficult to determine a calibration value for installation on

estimated calibration value and then fine-tune the calibration.

Any number between 10 and 15 (255 mm to 380 mm) is a

good starting value.

NOTE: For fine-tuning the SPEED CAL value, see Appendix B

on page 44.

Illustration 15

To determine SPEED CAL, measure the distance of

one complete wheel revolution and divide by the

number of magnets installed.

For the console to calculate the correct speed and measure

distanceaccurately,thecircumferenceofthesensor-equipped

wheel must be entered. Determine the circumference of the

sensor-mounted wheel to the nearest tenth of an inch (tenth

of a centimeter) with the following method:

METHOD

Mark the tire with a piece of chalk and measure the distance

traveled on the ground for one complete revolution. See

Illustration. For improved accuracy, it is recommended that

you perform this function in field conditions, measure several

revolutions, and take the average.

Divide the measured revolution by the number of magnets

installed to get your starting SPEED CAL calibration value.

Once calibration of the system is complete, this number

should be fine-tuned for optimum accuracy.

For fine-tuning the SPEED CAL value, see Appendix B on page 44.

7

EXITING CALIBRATION: Upon completion of the calibra-

tion process, exit calibration by pressing and holding the

CAL button until the RED warning light turns off (one sec-

ond). Basic calibration is now complete. BEFORE beginning

application, confirm that the system is set up to do the

job that you want it to. Please refer to Pre-Field System

Checkout to confirm calibration settings, nozzle selection

and overall system performance. NOTE: You must exit CAL

to save any changes.

TEST SPEED: Test speed is a built-in ground speed simulator

operating speed is

entered, the MT-3405F

II will respond as if you

were actually driving

that speed. It allows

you to simulate your

spraying application

with water, while

remaining stationary, to

make certain that all of the equipment is operating properly and

that your sprayer can actually perform the intended application.

Test speed will not accumulate Distance or Area measurements.

(The CAL indicator flashes to remind the user that TEST SPEED

mode is active.) TEST SPEED is cancelled by exiting CAL.

Calibration Factor Measurements Effected Default Values

English Metric

TARGET RATE Application Rate in Auto 10.00 gallons/acre 100.00 liters/hectare

ADJUST RATE Amount of increase or decrease per +/- press (in auto) 1.00 gallons/acre 10.00 liters/hectare

WIDTH BOOMS 1-3* Area, Application Rate 240 inches 6.000 meters

SPEED CAL Distance, Area, App. Rate, Area/Hour 0.189 inches 4.44 centimeters

MINimum FLOw App. Rate, Lowest Allowable Flow Rate 0.0 gallons/minute 0.0 liters/minutes

FLOW CALibration Flow/App. Rats, Volume 145.0 pulses/gallon 145.0 pulses/gallon

INLINE/BYPASS Application Rate Bypass Bypass

TEST SPEED none 0.00 0.00

* BOOMS 4 AND 5 ARE SET TO 0.

Calibration (cont)

Determining the SPEED CAL

Factory-Loaded Calibration Values