Contents

5

Switch off after .................................................................................................................... 94

Ready for operation (standby) ........................................................................................ 94

Auto-Off function............................................................................................................ 94

Switching off after activating.......................................................................................... 95

Factory default..................................................................................................................... 96

Software version.................................................................................................................. 96

Program settings ...............................................................................................................97

Adjusting program settings ................................................................................................. 97

Program structure................................................................................................................ 97

Program header.............................................................................................................. 97

Program blocks .............................................................................................................. 98

Opening the menu............................................................................................................... 99

Resetting a program.......................................................................................................... 100

Altering a program ............................................................................................................ 101

Allocating wash blocks................................................................................................. 102

Spray-arm monitoring .................................................................................................. 103

Changing water quantity .............................................................................................. 105

Increasing drainage time .............................................................................................. 106

Setting the concentration ............................................................................................. 107

Setting the wash block temperature ............................................................................ 108

Drying assistance ......................................................................................................... 110

Process documentation..................................................................................................112

Retrospective output of cycle reports............................................................................... 115

External software.......................................................................................................... 115

Report printer ............................................................................................................... 115

Maintenance measures...................................................................................................116

Maintenance...................................................................................................................... 116

Routine checks.................................................................................................................. 117

Cleaning the filters in the wash cabinet ............................................................................ 117

Checking and cleaning the spray arms ............................................................................. 119

Cleaning the machine........................................................................................................ 121

Cleaning the control panel ........................................................................................... 121

Cleaning the door and the door seal............................................................................ 121

Cleaning the wash cabinet ........................................................................................... 121

Cleaning the door front ................................................................................................ 121

Preventing resoiling ...................................................................................................... 121

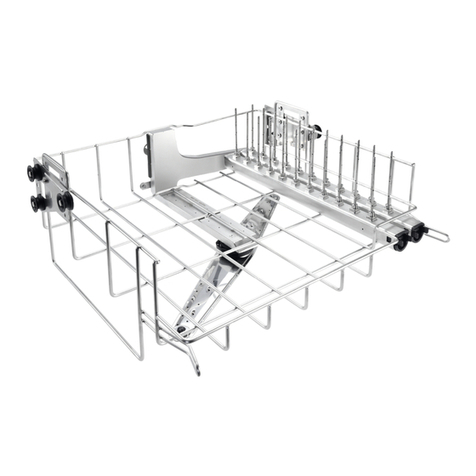

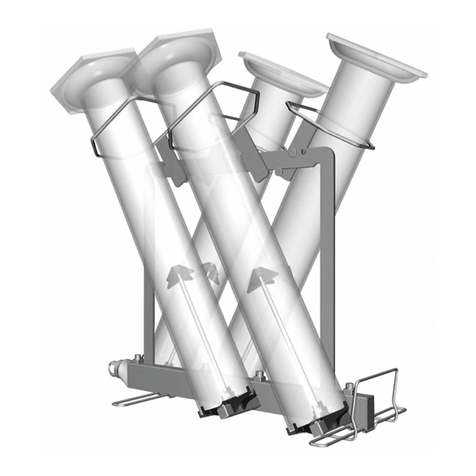

Checking mobile units, baskets, modules and inserts...................................................... 122

Performance check ........................................................................................................... 123

Frequently asked questions ...........................................................................................126

Technical faults and messages ......................................................................................... 126

Dispensing/dispensing systems........................................................................................ 127

Insufficient salt/water softener .......................................................................................... 129

Cancel with fault code....................................................................................................... 130

Process-related faults and messages ............................................................................... 134

Door................................................................................................................................... 135

Unsatisfactory cleaning and corrosion.............................................................................. 136

Spray arm monitoring/wash pressure ............................................................................... 139

Water inlet and drainage ................................................................................................... 140

Noises................................................................................................................................ 141