Manual Hand Tool for Picoflex® PF-50 Connectors

Doc No: ATS-6 00810 0 Release Date: 06-28-05 UNCONTROLLED COPY Page 4 of 6

Revision: F Revision Date: 07-17-12

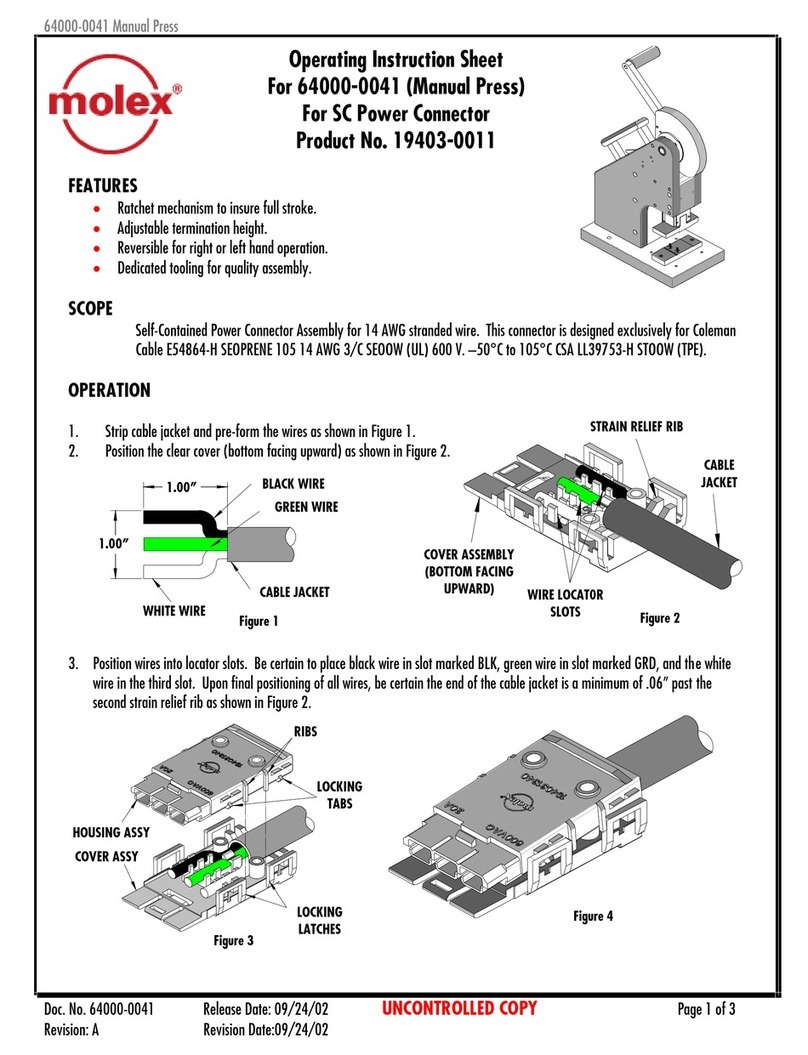

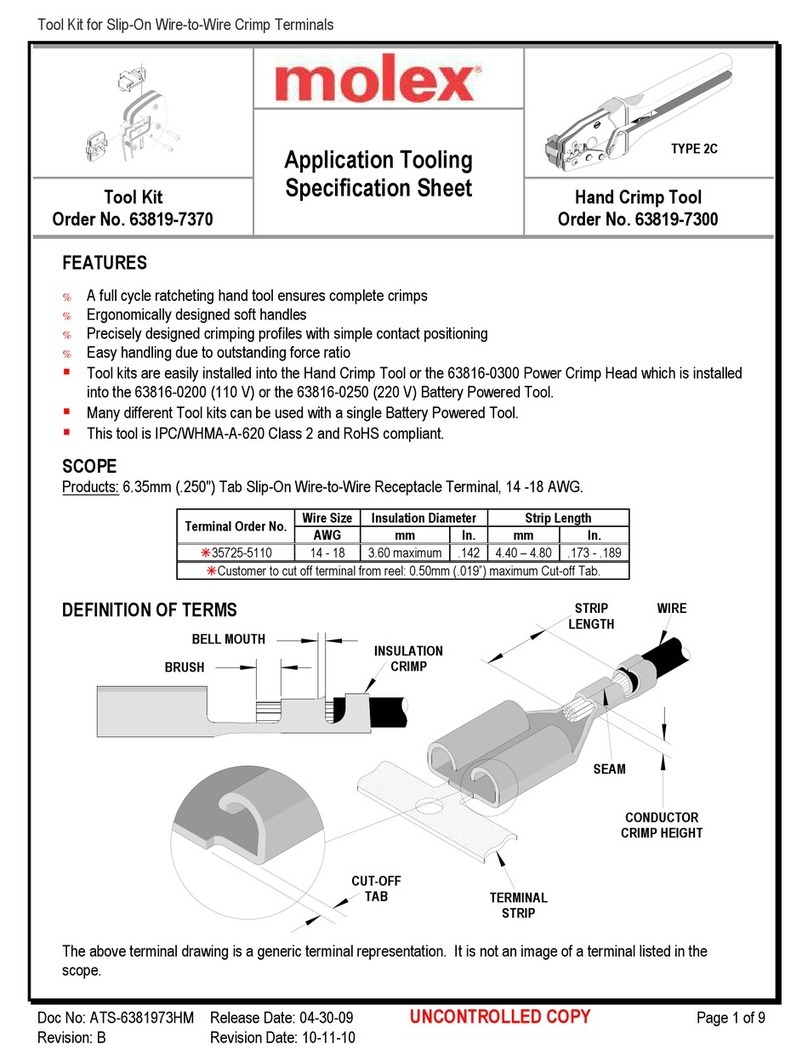

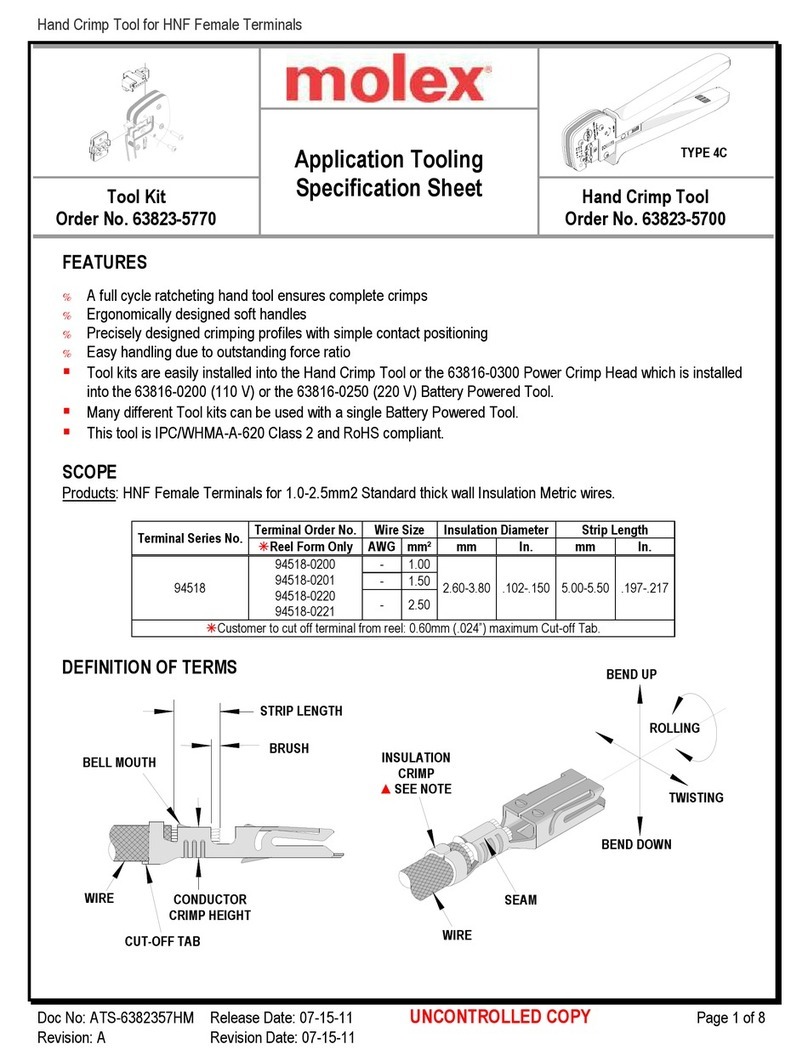

Figure 3

CABLE

BRACKET

TRACK

BRACKET

Cable Stop

The bracket on the back of the track is adjustable for Feed-To and Feed-Thru harnesses.

1. For Feed-To harnesses the bracket should fit flush and inside the track. See Figure 3.

2. For Feed-Thru harnesses unscrew the M3 SHCS.

3. Rotate the bracket 1800.

4. Tighten the M3 SHCS. See Figure 3.

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for, the following

maintenance steps:

1. Disassemble the metal tool frame by removing the screws and pulling off the plastic handle. Remove dust,

moisture, and other contaminants with a clean brush, or soft, lint free cloth.

2. Do not use any abrasive materials that could damage the tool.

3. Make certain all pins; pivot points and bearing surfaces are protected with a thin coat of high quality machine

oil. Do not oil excessively. Light oil used at the pivot points every 5,000 terminations will significantly enhance

the tool life.

4. Wipe excess oil from hand tool, particularly from termination area.

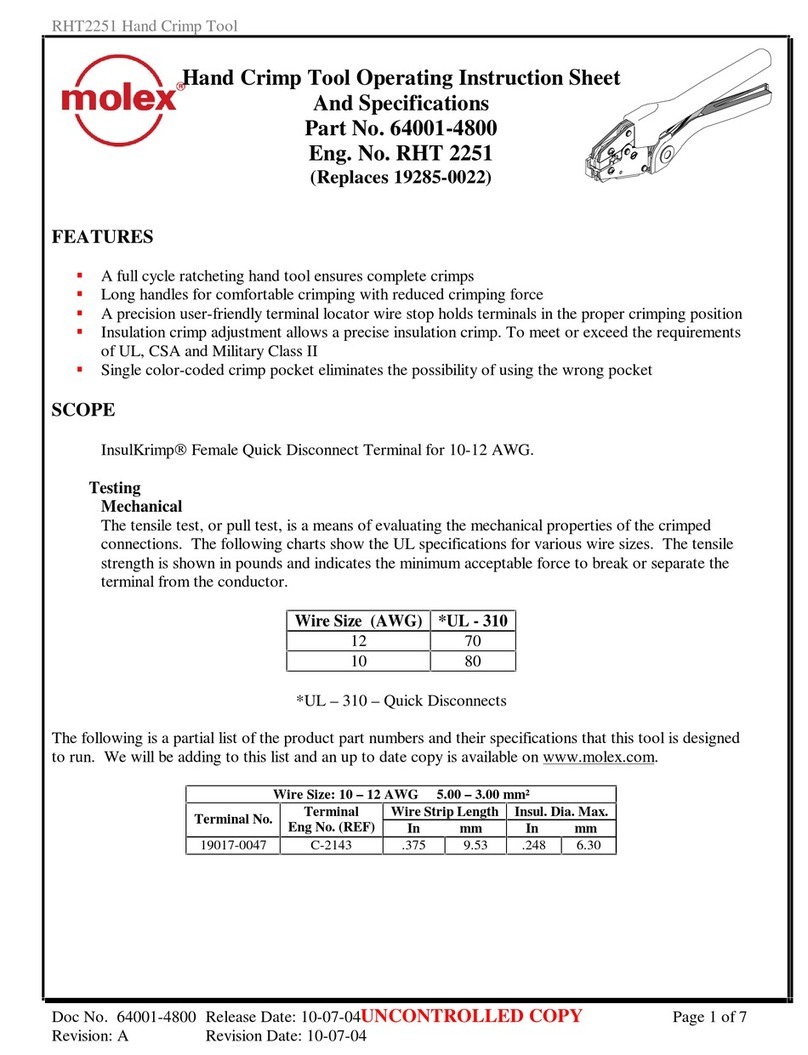

Missed Terminations or Jams

Should this tool ever become stuck or jammed in a partially closed position, DO NOT

force the handles open or closed. The tool will open easily by pressing the ratchet

release lever up. See Figure 4.

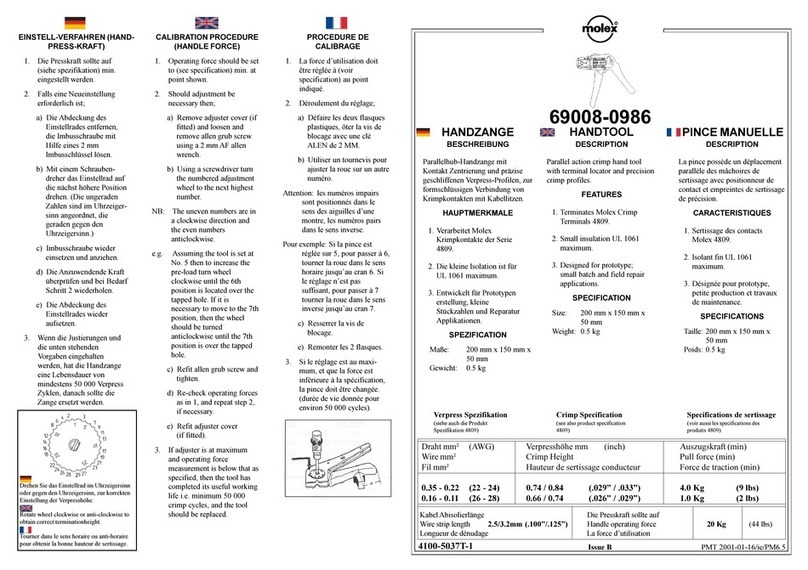

How to Adjust Tool Preload

It may be necessary over the life of the tool to adjust tool handle preload force.

Listed below are the steps required to adjust the force of the hand tool to obtain the

proper termination conditions:

1. Remove the 2mm locking screw from the numbered adjusting wheel using a

screw driver. See Figure 4.

RELEASE LEVER

Figure 4