3.5 Electrical installation

3.5.1 Safety notes

3.5.2 Important information

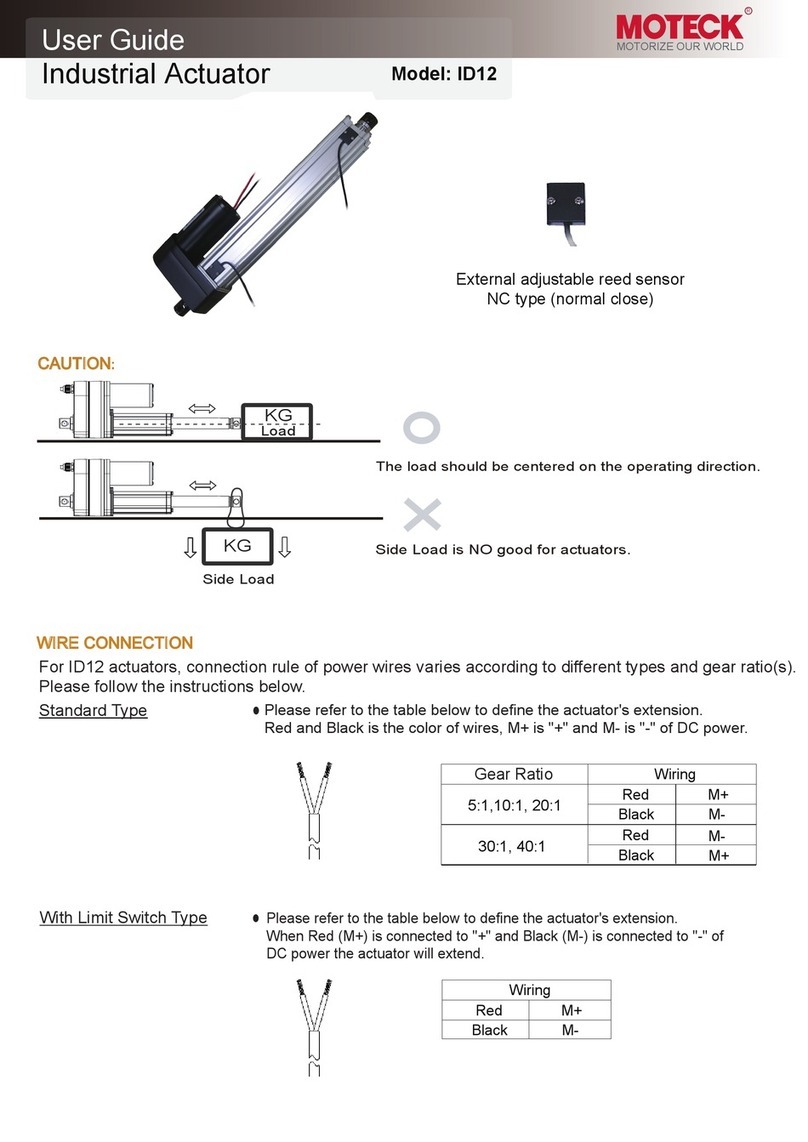

3.5.3 Fuse specification

Install a slow-blow fuse of this specification between the actuator and the power supply for protection.

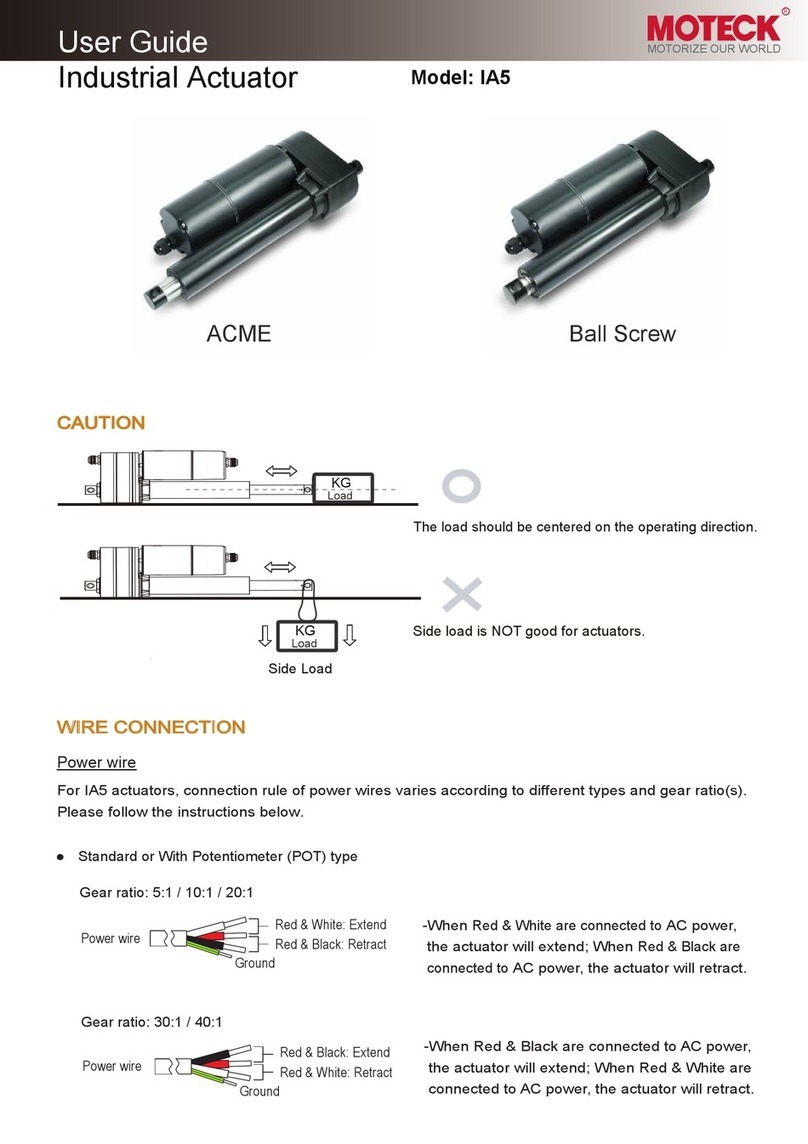

3.5.4 Electrical connections

Actuator is equipped with a power cable and a signal cable. One end of each cable has been plugged and fixed

on the actuator before shipment, and the other end are bare wire contacts for customers to connect power and

signal transmission. Please check the model number on the product label (section 3.1) first, then refer to the

model coding (section 6.2) to identify the control options of the actuator, and connect the power cable and signal

cable correctly according to the description of each control option (section 3.6).

www.moteck.com

9

●If users extend the power cord, Make sure that your own power extension

cord can withstand the maximum operating current of the actuator.

●It is recommended to install an emergency stop switch at a suitable location

of the power supply line.

●Do not perform wiring without cutting off the power supply.

●Before controlling the action of the actuator, it must be noted that the

actuator and its connected mechanical moving parts are not blocked by

other objects, and no one enters the dangerous area.

● It is forbidden to wind the signal cable with the power cable to avoid

interference with the signal.

● Avoid using the vehicle as a ground to reduce the risk of interference.

● The longer the power cord length or the smaller the wire diameter, the

worse the voltage drop. When the voltage of the power supply is low, it is

more likely to cause insufficient voltage and cause malfunctions.

● Relays or other coils on operating equipment should have spark protection

to avoid interference.

● Do not install or wire the actuator without cutting off the power supply.

●Before using the hand crank, be sure to turn off the actuator power. Do not

apply torque exceeding 1.7Nm on the hand crank.

●Do not move the extension tube to both ends of the stroke, otherwise the

actuator might be damaged.

●Do not use any type of automatic drill or power tools to drive the manual

crank.

Input voltage

12V DC

Fuse specification

40A

24V DC 20A