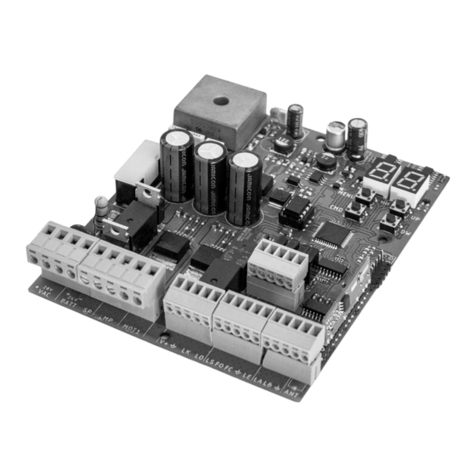

Motorline professional MC41SP Instruction Manual

Other Motorline professional Control Unit manuals

Motorline professional

Motorline professional MC112N Use and care manual

Motorline professional

Motorline professional MC61SE Operation and installation manual

Motorline professional

Motorline professional MC60 Use and care manual

Motorline professional

Motorline professional MC102 Instruction Manual

Motorline professional

Motorline professional MC112PR User manual

Motorline professional

Motorline professional MC70 EVO Instruction Manual

Motorline professional

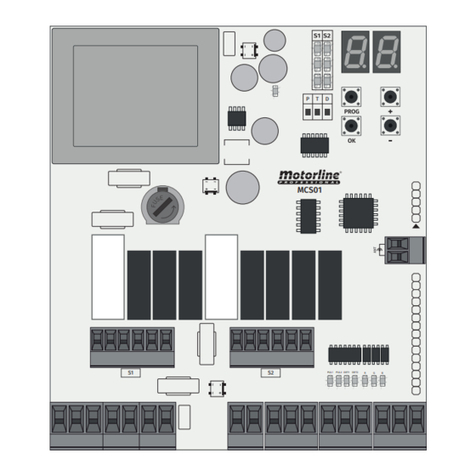

Motorline professional MCS01 Instruction Manual

Motorline professional

Motorline professional MCONNECT SHUTTER Use and care manual

Motorline professional

Motorline professional MC61PL Instruction Manual

Motorline professional

Motorline professional MC61PL Operation and installation manual

Motorline professional

Motorline professional MC75 Use and care manual

Motorline professional

Motorline professional MC15BA Instruction Manual

Motorline professional

Motorline professional MC70 Instruction Manual

Motorline professional

Motorline professional MC4 EVO User manual

Motorline professional

Motorline professional MC61BR Operation and installation manual

Motorline professional

Motorline professional MC7 Operation and installation manual

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual