Reading method: it is the reading method of current measurement parameters.

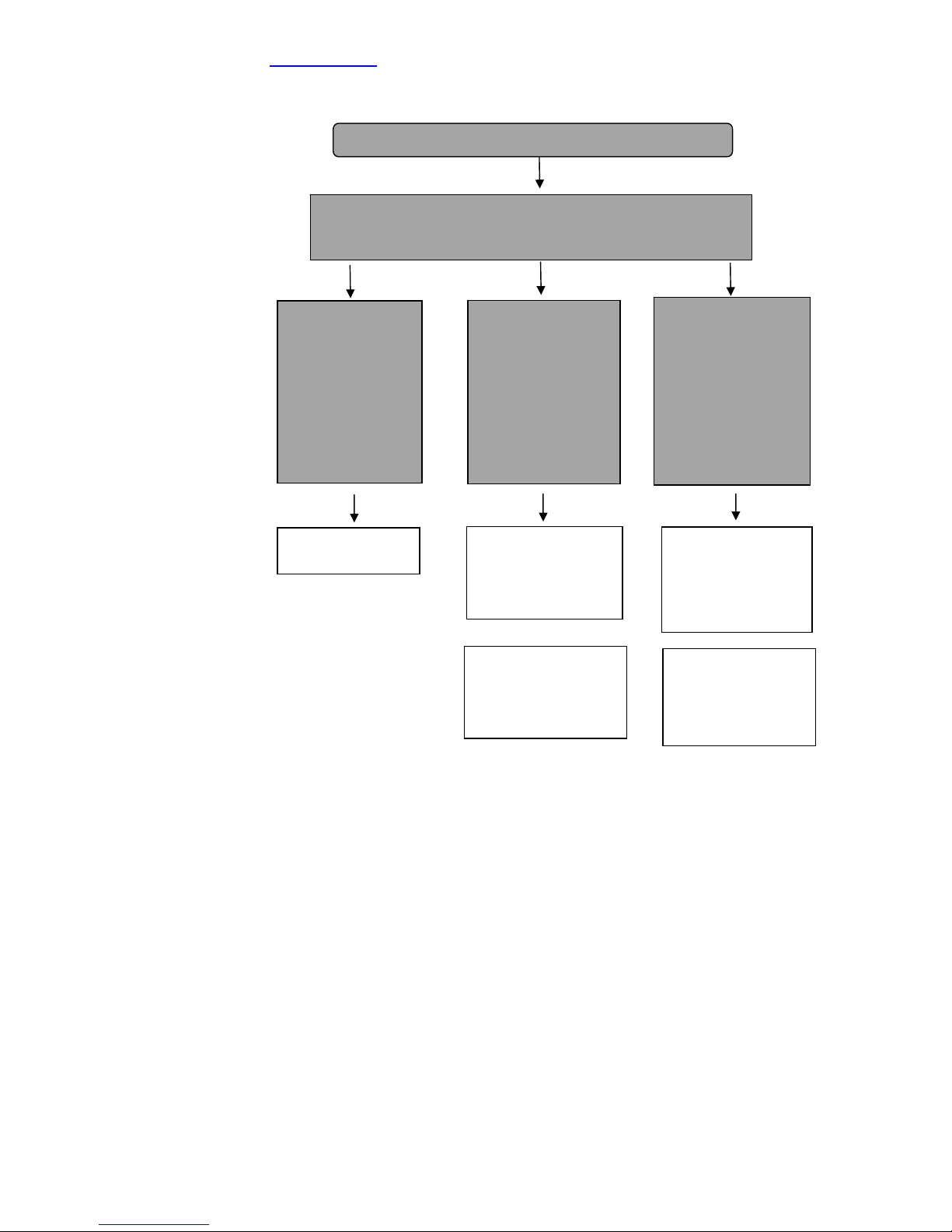

The meter supports three reading methods, continuous reading method, smart

reading methods and timed reading method.

Continuous reading method: This reading method is suitable for continuous

monitoring of

the sample data, observing the change trend of sample. It

requires user to manually terminate the measurement.

Smart reading method: Set the balance condition first. When the measurement

started, the

meter will automatic measure, calculate and display the measured

value, once meet the balance condition, this measurement is finised

finished.

Balance conditions includes balance time and balance value. When all

the measured values meets the demand of balance

value at the set balance time. It means satisfies

balance conditions, this measurement is finished.

The meter provide four balance conditions to select, "Fast, Medium,

Strict, Custom", different parameters have different

balance conditions. Fast, medium, and strict are three

kinds of balance conditions provided by the meter, the

user cannot modify. User is only allowed to modify

custom type balance conditions.

Note: User needs to manually save the measurement result.

Timed reading method: The meter supports two timing reading methods, one is

fixed time reading method, another is fixed interval

time reading method.

Fixed time reading method: When the measurement

started, the meter works until the set time, for example

set the time as 300 seconds, the meter will

continuously measure for 300 seconds.

Note: Fixed time method does not automatically save measuring results.

Fixed interval time reading method: User needs to set

measurement interval time and measurement quantity,

then the meter will automatically collect and record data

according to the set interval, the minimum time interval

is 1 second.

Calibration result, it is the last calibration results of used electrode, is also the

electrode parameter of current measurement parameters to be used.

Corrector, it is the calibration operator last time.

Correction time, it is the last calibration time.

Temperature compensation coefficient, this parameter is corresponding to the

conductivity, TDS and salinity measurement parameters. When user needs to

measure in high accuracy, the influence of the temperature will lead to inaccurate

conductivity measurement, set temperature compensation coefficient, the default

value is 0.020, that is 2.00% / .