MTS Sensors

R-Series Temposonics®Linear-Position Sensors - Model RF Flexible Housing Option

Product Data Sheet, Document Part No.: 551081, Revision B 10/11 2

Product specifications

Parameters Specifications

OUTPUT

Measured

output

variables:

Position, velocity, simultaneous multi-

position and velocity measurements.

(Measured output variables depend on the

complete sensor model used.)

Resolution: Output dependent

Update times: Output dependent

Linearity

deviation: < ± 0.02% full stroke (minimum ± 100 µm)

Linearity Correction Option (LCO) available

for some R-Series models

Repeatability: < ± 0.001% full stroke (minimum ± 2.5 µm)

Hysteresis: < 4 µm, 2 µm typical

Outputs: Voltage, current, SSI, CANbus, DeviceNet,

Profibus, EtherCAT and EtherNet/IP

Measuring

range:

255 to 10,060 mm (10 to 396 in.)

(Contact factory for longer stroke lengths)

ELECTRONICS

Operating

voltage:

+24 Vdc nominal: -15% or +20%

Polarity protection: up to -30 Vdc

Over voltage protection: up to 36 Vdc

Current drain: Output dependent

Dielectric withstand voltage: 500 Vdc

(DC ground to machine ground)

ENVIRONMENTAL

Operating

conditions:

Operating temperature:

-40 °C (-40 °F) to +75 °C (+167 °F)

Relative humidity: 90% no condensation

EMC test: Emissions: IEC/EN 50081-1

Immunity: IEC/EN 50082-2

IEC/EN 61000-4-2/3/4/6, level 3/4

criterium A, CE qualified

Shock rating: 100 g (single hit)/

IEC standard 68-2-27 (survivability)

Vibration rating: 5 g/10 to 2000 Hz, IEC standard 68-2-6

(operational)

WIRING

Connection type: Connector or integral cable (output

dependent)

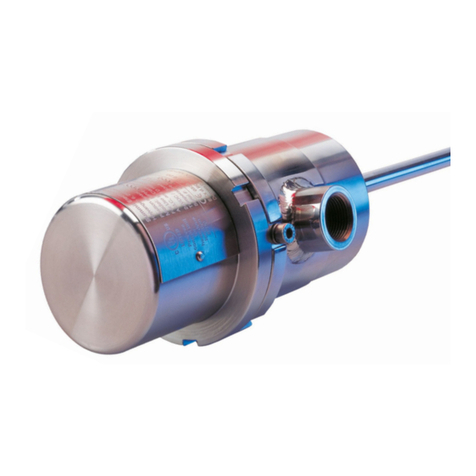

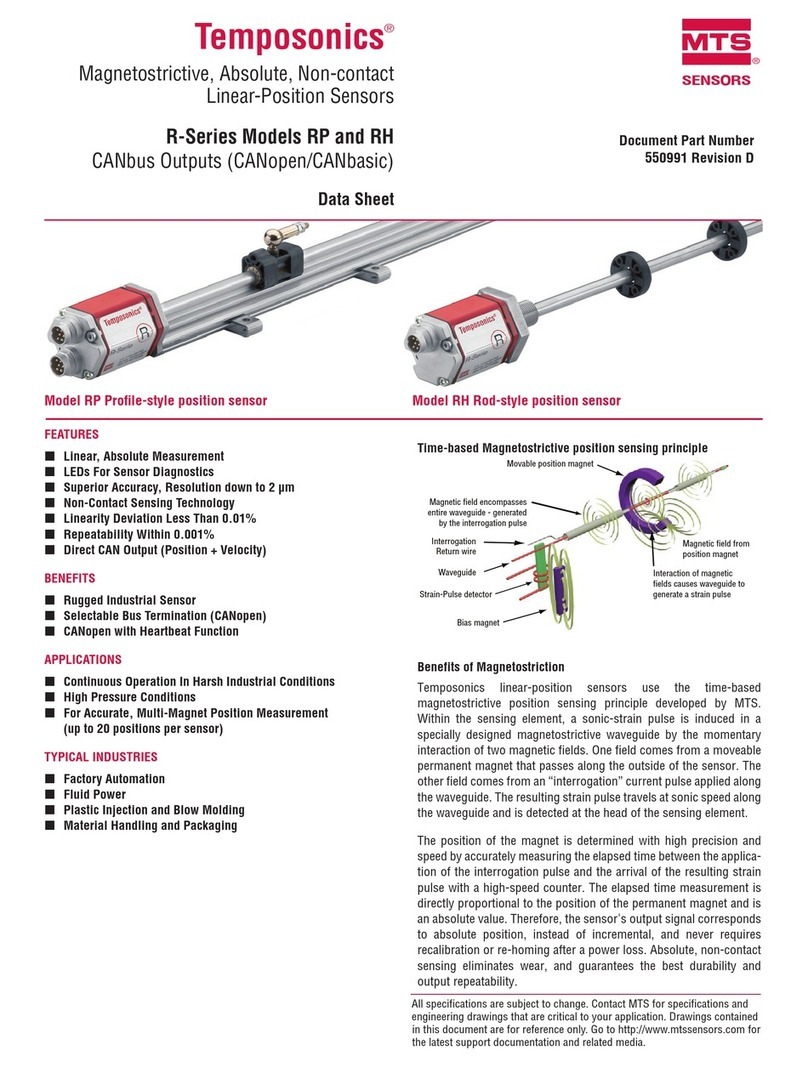

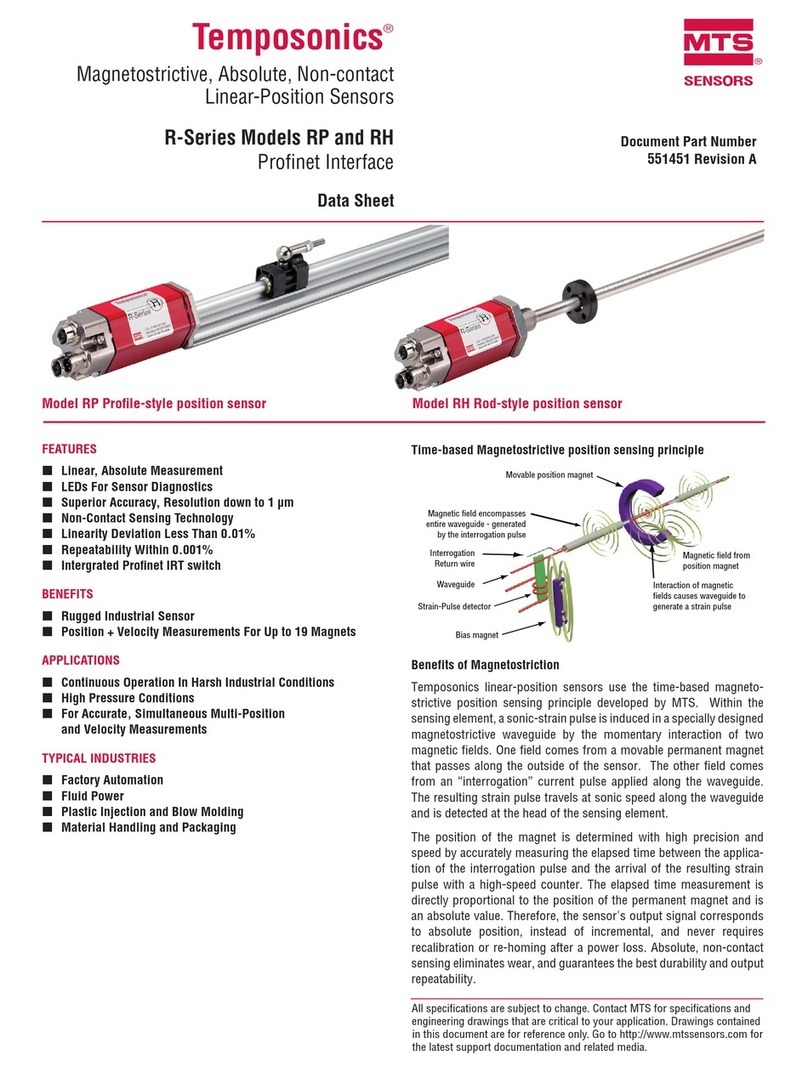

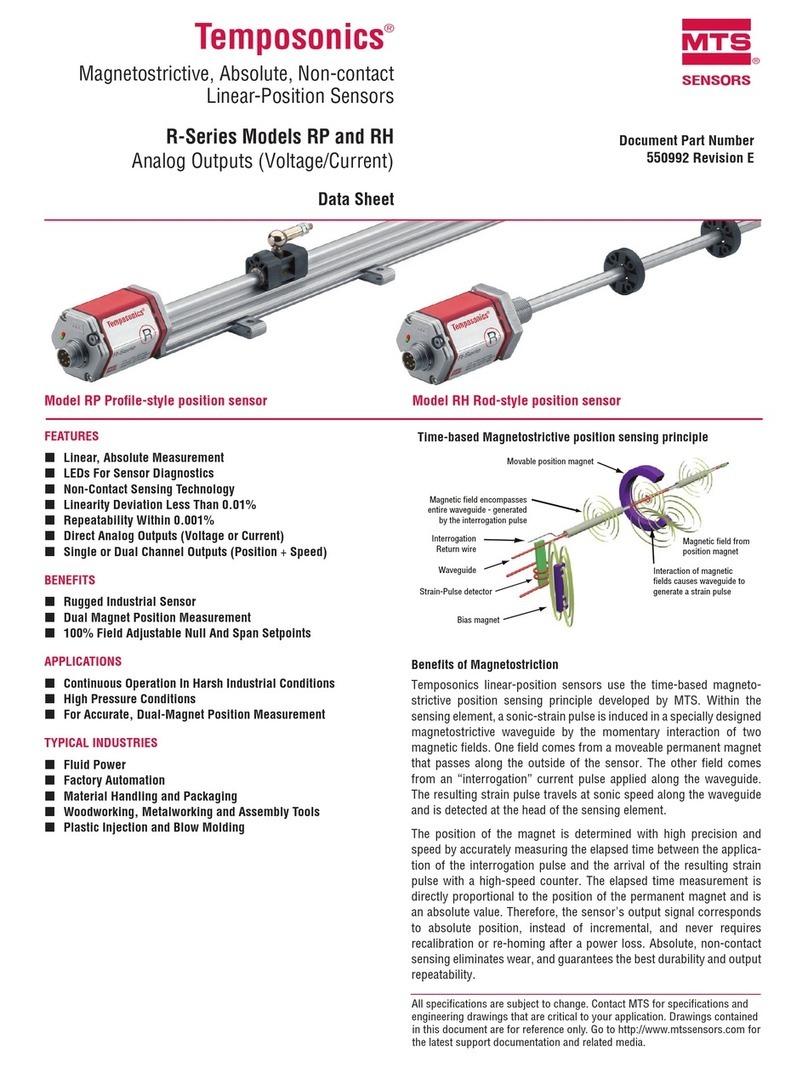

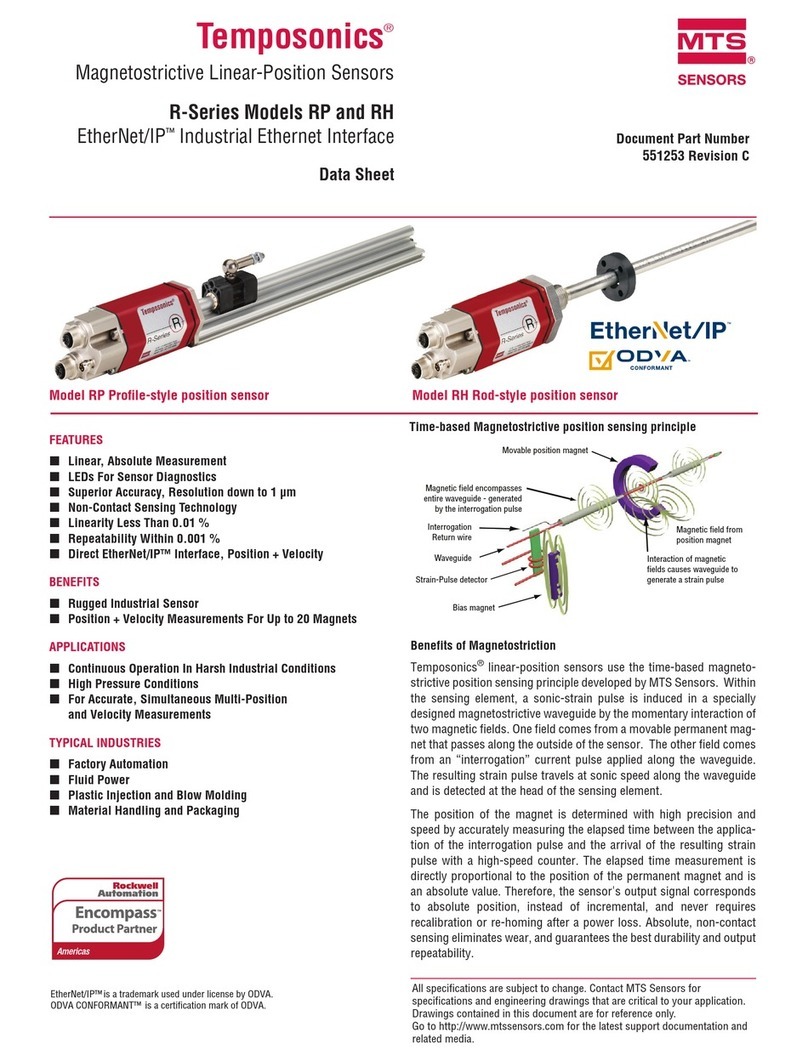

ROD STYLE SENSOR (MODEL RF)

Electronic head: Aluminum die cast housing with diagnostic

LED display

(LEDs located beside connector/cable exit)

Sensor stroke: Flexible stainless-steel pipe (PTFE plastic

coated), minimum bend radius 200 mm (8 in.)

Sealing: IP 30 (IP 67 or IP 68 rating when installed

inside the optional 1/2 inch O.D. pressure

housing pipe)

Mounting: Any orientation. Threaded flange M18 x 1.5

or 3/4 - 16 UNF-3A

Magnet types: Ring magnet or open-ring magnet or block

magnet

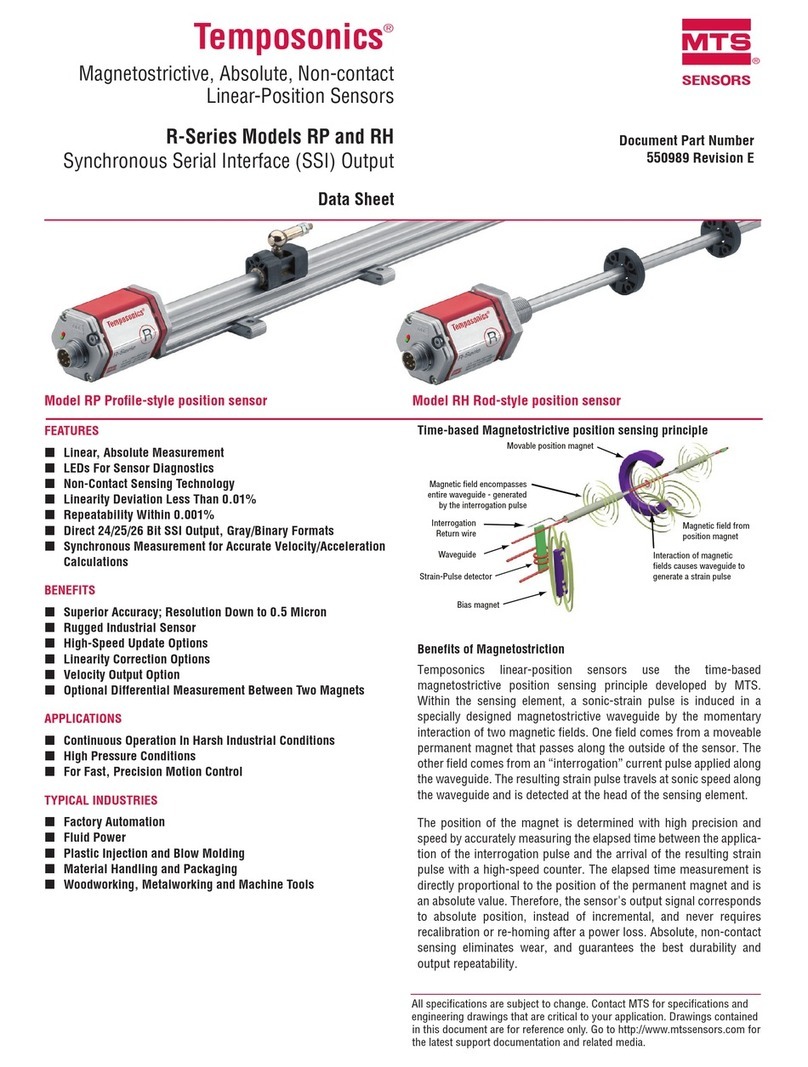

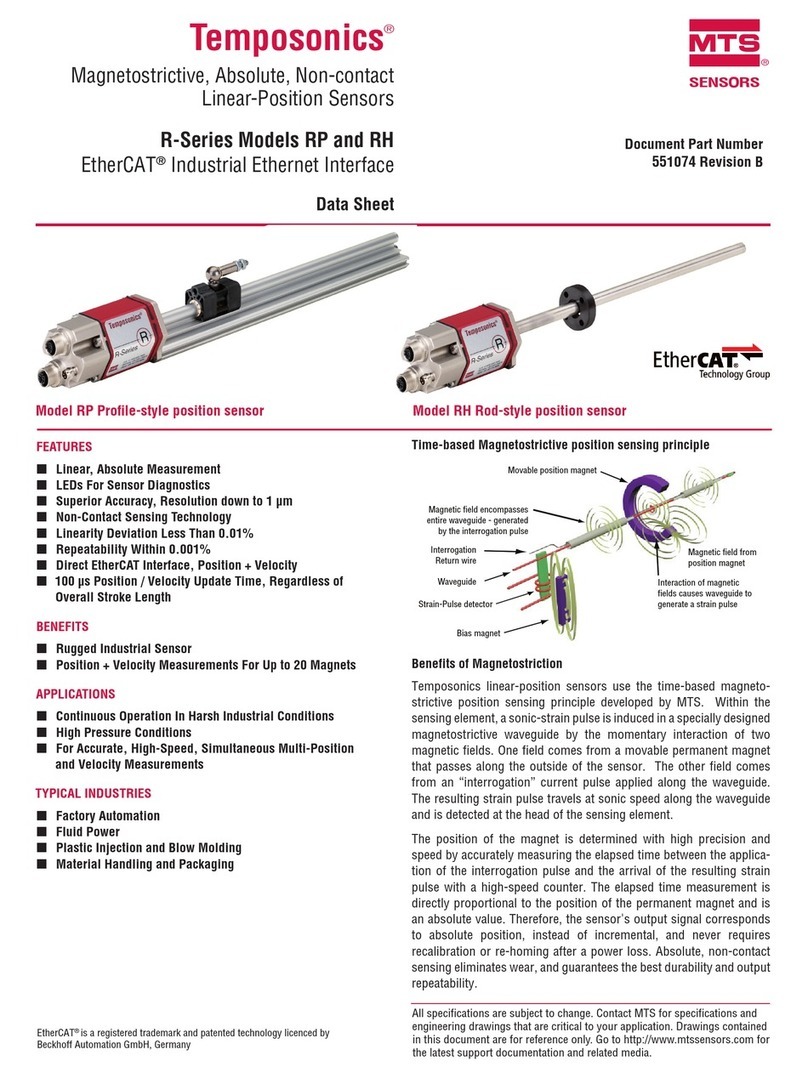

Product overview

MTS offers the Model RF Flexible housing as an option with our

R-Series family of extremely robust, highly accurate, linear-position

sensors.

Constructing a R-Series sensor with the RF flexible housing results

in a flexible style sensor that offers trouble-free performance

in applications that require very long stroke lengths and linear

measurements on an arc.

The Model RF flexible sensors are available in all R-Series sensor

outputs including analog, serial, digital, and bus interfaces.

Standard stroke lengths for the sensor are up to 10 meters (396

in.) and for special applications, longer lengths are available by

consulting the factory.

Flexible sensors incorporate the Temposonics SE (Sensing Element)

technology that is the same building block all MTS sensor models

use. The SE is housed in a fluoroelastomer coated stainless steel

housing that is flexible and can be bent in an arc to an 8 inch

minimum bend radius.

Most operating parameters are identical to their rigid cousins.

Model RF sensors are recommended for long-length applications

because they are simply coiled inside a 40-inch diameter box for

shipping, which simplifies logistics and handling.

The model RF sensor can easily bend around corners or obstacles

and provides a simple solution for applications where installation

space is too confined, or has limited access, making installation or

replacement too difficult and costly for a standard rigid type sensor.

Output options

The Model RF Flexible Housing option is available for R-Series

Sensors with voltage, current, SSI, CANbus, DeviceNet, Profibus,

EtherCAT and EtherNet/IP outputs.

Important specification notes:

1. For R-Series model specific specifications, consult the individual

R-Series data sheets applicable to the sensor output(s) being used.

2. All sensors constructed with the flexible housing have their

specifications measured while laying flat.

Product Overview and Specifications