3

ENGLISH GERMAN FRENCH SPANISH ITALIAN

• This product does not consider operator’s age (mature person), height, weight, gender, or nationality.

• Users are responsible for the operational control, maintenance and continual inspection of this product.

• Do not attempt to disassemble the product nor tamper with the mechanism except as recommend by NSK in this Operation Manual.

• Do not allow any impact on to the product. Do not drop the product.

• Operators and all others in the area must wear eye protection and a mask when operating this handpiece.

• Should the product function abnormally, cease operation immediately and contact your Authorized NSK Dealer.

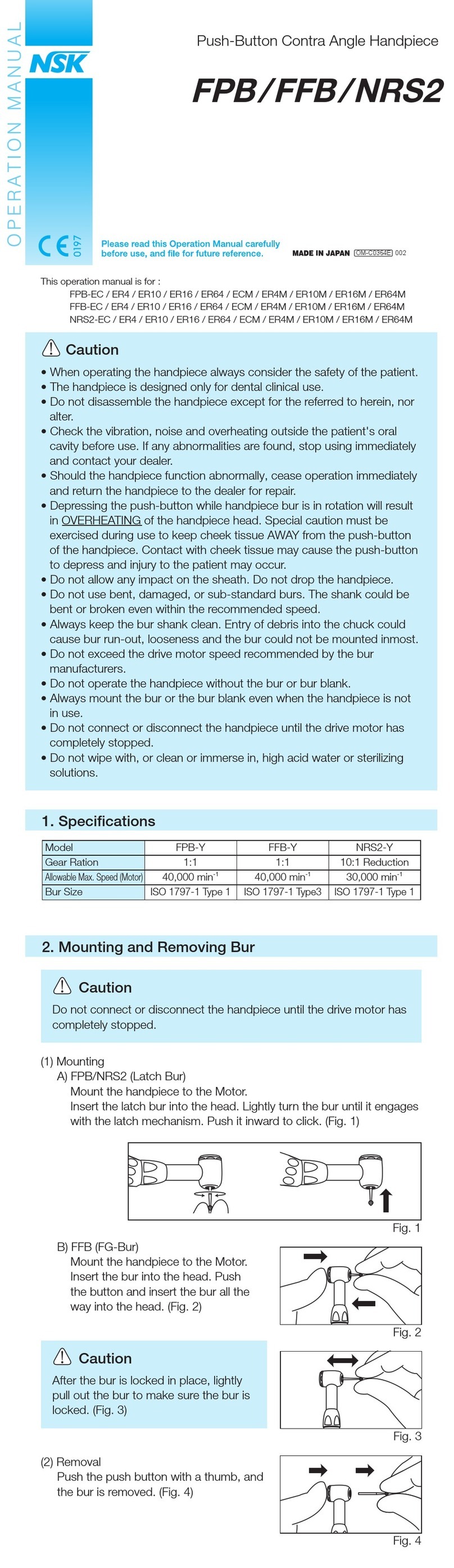

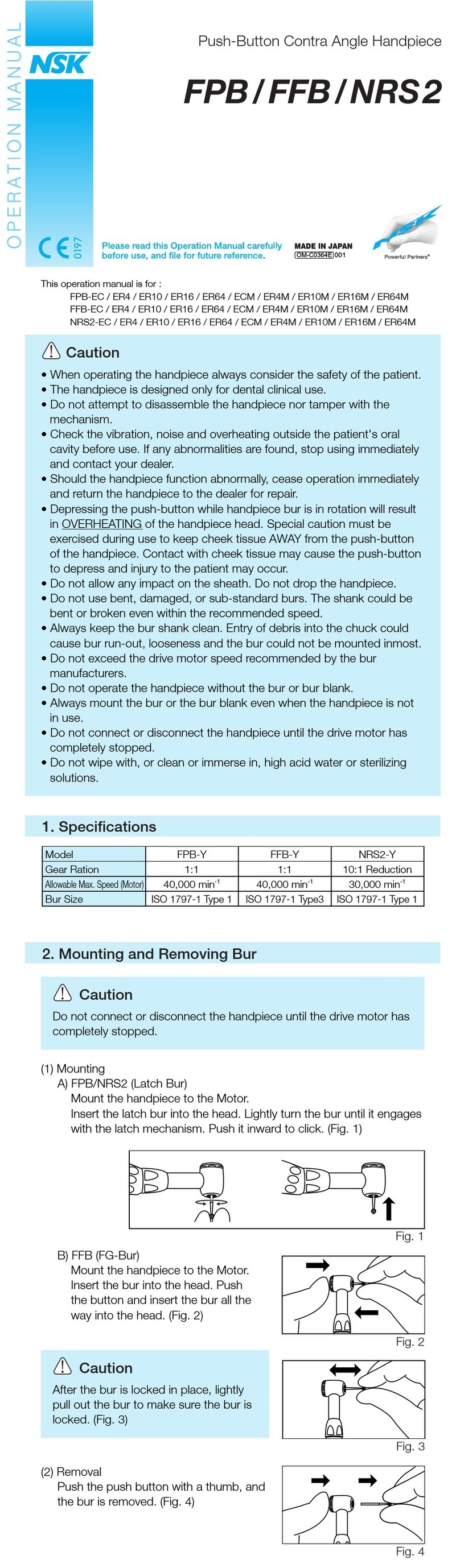

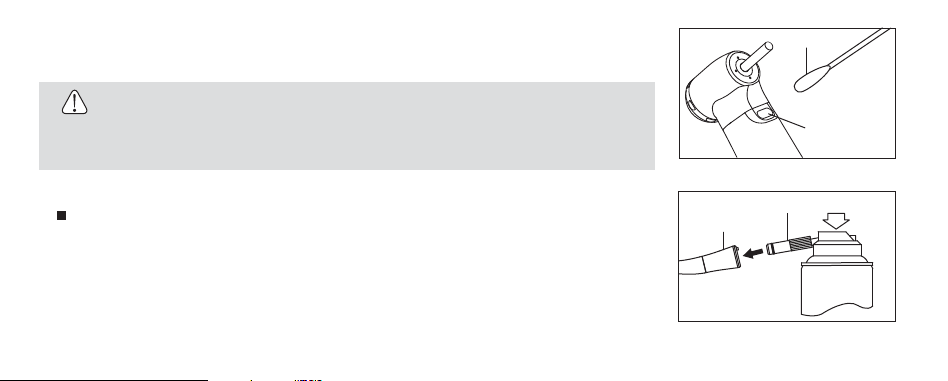

• Depressing the Push Button while the handpiece is in operation may cause overheating, serious technical damage and possible premature

handpiece failure. During operation avoid contact with any oral tissue that may cause the Push Button to be depressed while the handpiece is

in operation.

• Supply coolant water and coolant air while operating the handpiece. The handpiece may overheat or fail if the coolant water and coolant air

are not supplied properly.

• Do not use high acid water or sterilizing solutions to wipe, immerse or clean the product.

• The products are delivered in a non-sterile condition and must be autoclaved prior to use.

• Perform regular function and maintenance checks.

• If the product is not used for a long period check it is functioning correctly before using on a patient.

• To avoid clinical downtime it is recommended that a spare be kept on hand in case of a breakdown during surgery.