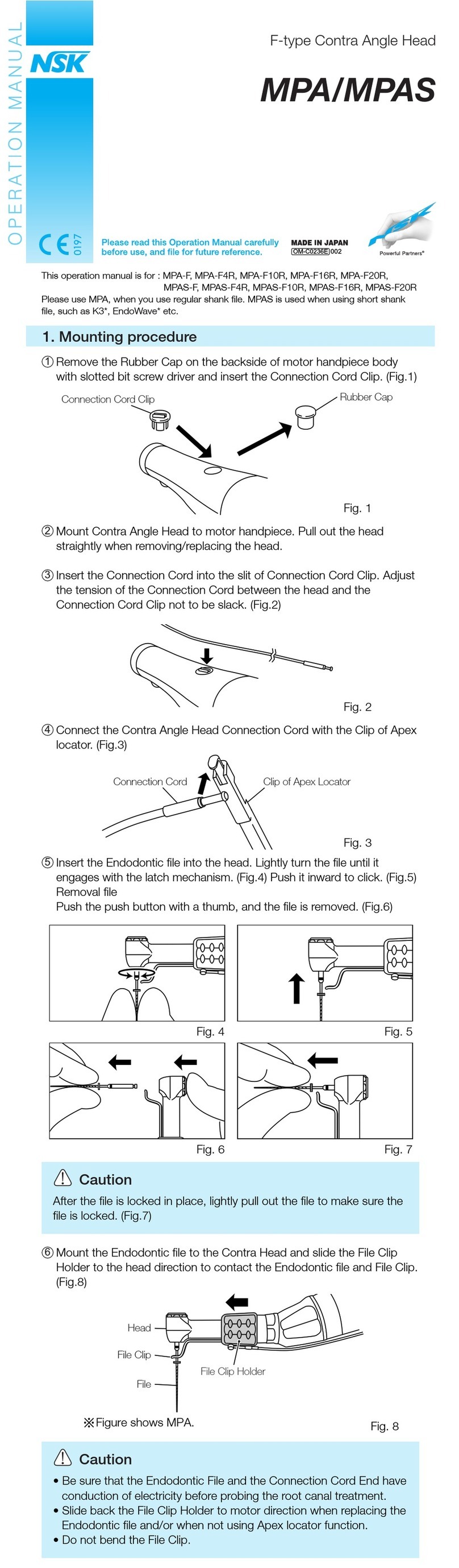

9.Sterilization

10.Cleanupaftereachpatient

11.ReplacingCartridge

12.ReplacingHalogenLamp

13.ReplacingwornO-ringinthehandpiece

14.Cleaningofthefiberopticend(A500L,A600L,A700L)

15.CleaningofSprayPorts

16.Non-RetractionValve

・Skipdrycycle.

・Heatingelementmaybelocatedthebottomofthechamber,andthetemperaturetherelocallymayexceedtheset

value.Placethehandpieseonthecentraloruppertray.

Sterilizationbyautoclaveisrecommended.

Sterilizationrequiredaftereachpatientasnotedbelow.

AUTOCLAVING:

① Brushoffexcessdirtandwipecleanwithalcohol-soakedcloth.

② RemovethehandpiecefromthecouplingandlubricatewithPANA-SPRAYasdescribedintheLubricationsection.

③ Insertthehandpieceinasterilizationpouchandsealit.

④ Autoclavableuptoamax.135℃.

ex.)Autoclavefor20min.at121℃,or15min.at132℃.

⑤ Keepthehandpieceintheautoclavepouchtokeepitcleanuntilyouuseit.

※ Sterilizationat121℃formorethan15minutesisrecommendedbyEN13060orEN554.

※ Performingsterilizationaccordingtoourinstructionhasminimaleffectontheinstruments.Lifespanisgenerallydetermined

bywearanddamageduetouse.

ItisimportanttocleantheslitintheheadasfollowsaftereachpatientandbeforeautoclavingtoappreciatelastingCLEAN-

HEADperformance.(Fig.8)

① BrushoffthedebrisattheslitsasshowninFig.9.

② Runthehandpieceattheratedpressure.

③ Immersehalfoftheheadincleanwaterwhilethehandpieceisrunning.

④ Runthehandpieceinthewater4−5seconds.(Fig.10)

⑤ Removethehandpiece,whilerunning,fromthewater.Stopandwipedrythehandpiece.

⑥ Lubricatebeforeautoclaving.

*Note:Changewatereachtime.

a Removingthecartridge

① Mountadummyburinthechuck.

② Setthewrenchontheheadcap,turnthewrenchcounter-clockwiseand

removethecap.(Fig.11)

③ Pushupthedummybur,andthecartridgeiseasilyremovedfromthehead.

④ Cleantheheadinterior,whendirty,withPANA-SPRAY.

Fig.11

Fig.12

s Insertingthenewcartridge

① Insertthenewcartridge,withitspinalignedintheslotofthehandpiecehead,straightintothehandpiece.

② Handtightenthecapuntilfingertightandsecurewithwrenchuntilthecapsetsinplace.(Fig.12)

※OptionalCartridge:Ti-MU03(CartridgeforMiniaturehead)OrderNo.P057

Ti-SU03(CartridgeforStandardhead)OrderNo.P058

Ti-TU03(CartridgeforTorquehead)OrderNo.P059

Fig.13

・Theheadcapscrewthreadisveryfine.Topreventitfrombreaking,useofthe

wrenchfromthefirstthreadisnotrecommended.

・Beforeinsertinganewcartridge,cleantheheadinterior.

・MakesurethattwoO-rings(Fig.13)areinplaceonthecartridge.

Fig.15

Ahalogenlampisinsidethequick-connectcoupling.

① Removethehandpiecefromthecoupling.

Turntheserratedringontheconnectorclockwiseandremovethebackend.

Thelampisinthebackendmember.(Fig.14)

② Pulloutthelamp.(Fig.15)

③ Insertanewlampandalignitspinswiththesocketholes.

Pushitin.(Fig.16)

④ Assembleinthereverseorder.Besuretoalignthetubesinthemale

memberwiththecorrespondingholesinthebackendmember.

Tightentheserratedringsecurely.

※OptionalLamp:PTLBulb(Packof3)OrderNo.Y900-529

Fig.17

Fig.19

① Removethehandpiecefromthecoupling.Unscrewthetaperedbodyofthehandpiecebyturningitcounter-clockwise.

(Fig.17)

② PushoutthewornO-ringwithyourthumb.(Fig.18)

③ InsertnewO-ringintheO-ringgroove.

④ Screwthetaperedbodysecurelybackontothehandpiece.(Fig.19)

Makesureitissecurelytightened.

※OptionalO-ring:PTLO-ringSet(Packof5)OrderNo.Y900-580

Fig.20Fig.20

Incasethelighthasbecomedim,cleanthefiberopticendwithanalcohol-soakedcottonswab.

(Fig.20)

Donotuseapointedtoolorsharpedgestocleanthefiberend.Theymaydamagethemirror

finishandreducethelighttransmissionefficiency.

Ifthefiberopticendhasbecomedamaged,sendthehandpiecetoyourlocaldistributorforrepair.

Whenspraynozzleareclogged,orspraydoesnotexitevenlyfromthreeports,cleantheportsasfollows:

① Removetheburorburblankfromthechuck.Removetheheadcap,andthecartridgefromthehead.

AsdiscribedintheReplacingCartridge.

② Takeoutthecleaningwirefromthebackendofthebrushholder.Insertthewirestraightintothe

spraynozzlewithcaution.Donotforciblyinsertthewireintotheport.Damagedordisorientedport

couldcausethespraydivergeordirectedawayfromthebur,andthecoolingefficiencydeteriorates.

SeeFig.21.

③ Makesurethatcleaningwirereachestothegroove,andbrushoffthedebris.

④ Afteruse,cleanthecleaningwire.Pushintothebrushholderwiththepointedendofthewire

inward.

Anon-retractionvalveisequippedintheCouplingJoint,whichshutsoffthe

waterretractionrightatthehandpiecehead,topreventoralfluidssuckedinto

thewaterline.Onceinawhile,useasyringetocheckitseffectivenessand

injectairtocleanthevalveseat.(Fig.22)

!

Airorwaterleakmayoccurifconnectionisloose.

!

Alooseconnectionmayresultinanairorwaterleak,or,insome

case,thehandpiecemaygetstuckonthecoupling.

!

Fig.8 Fig.10

Slit

Insert SerratedRing

Lamp Fig.14

Pins SocketHoles

Fig.16

Fig.15

Fig.18

CottonSwab

FiberOpticEnd

Fig.21

Note:Syringeisnotsuppliedwiththehandpiece.

Fig.22

PullPull

When the valve does not seem functioning, use the syringe and

inject air into the water tube of the back-end. Most dirt may be

blownoutoftheseat.

Toreplacethevalve,removetheback-endgasket.Pullandremove

thewatertube,andreplacetheNon-RetractionValve.(Fig.23)

Fig.23

WaterTube Non-RetractionValve

Gasket

O-rings

Fig.9

!

Slot

Wrench

Cartridge HeadCap

Pin

ThishandpiececanbewashedviaThermoDisinfector.

07.06.02◯

M