1

English

English

Contents

1. User and Intended Purpose ............................... 2

2. Precautions for Handling and Operation ............. 2

3. Product Description .......................................... 5

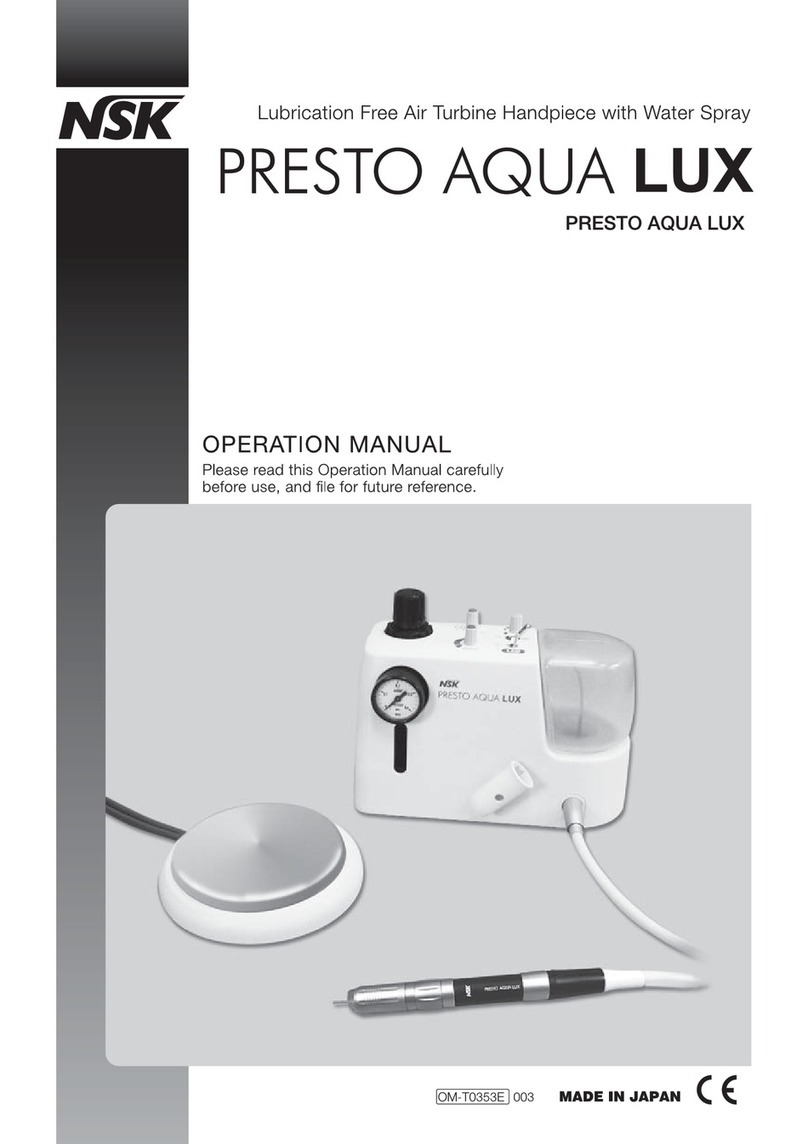

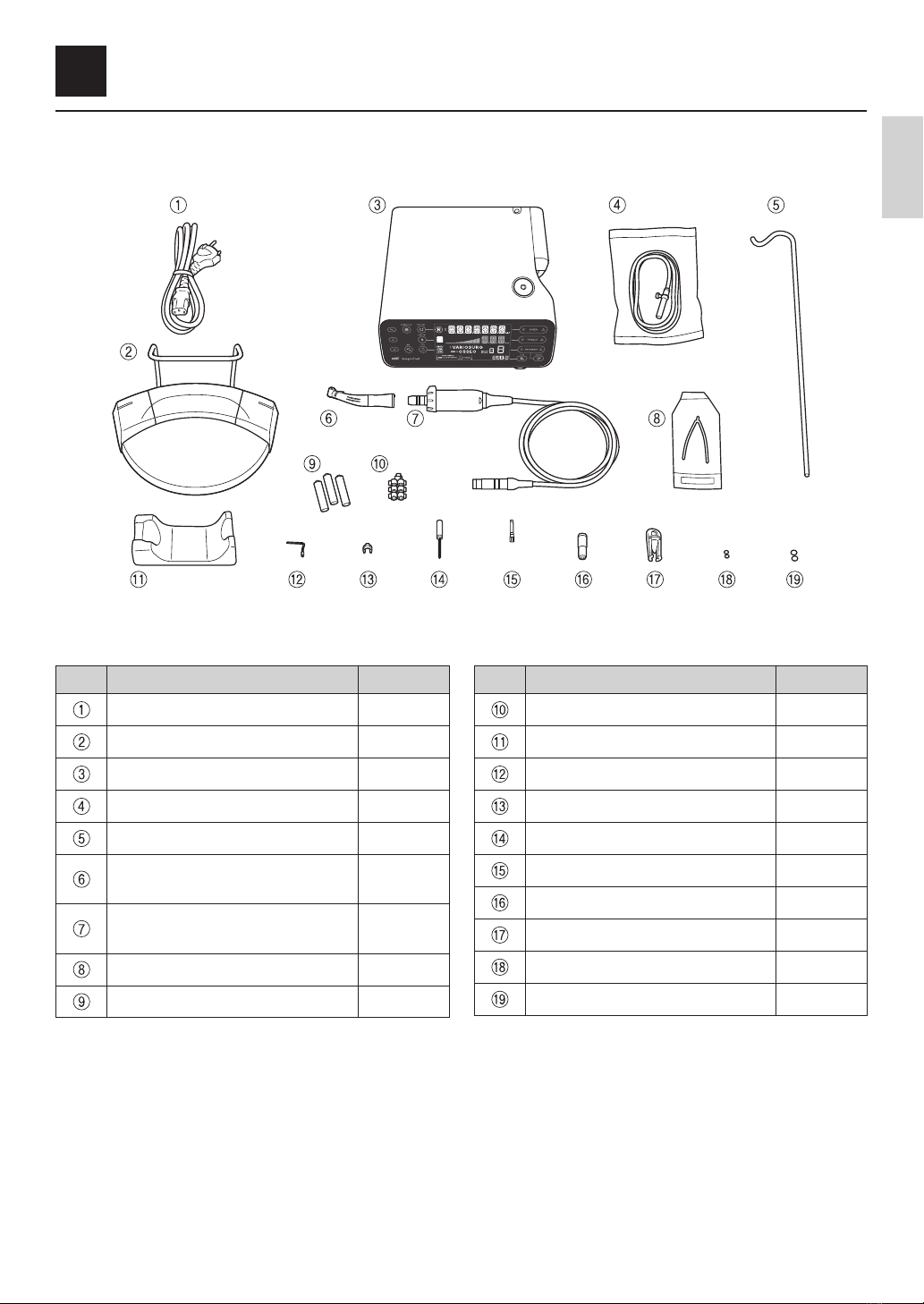

3–1 Package contents ������������������������������������������������������� 5

3–2 Control unit, foot control ���������������������������������������������� 6

3–3 Control panel �������������������������������������������������������������� 8

4. Preparation for Use ......................................... 10

4–1 Connecting the AC power cord ����������������������������������� 10

4–2 Installing foot control batteries ����������������������������������� 10

4–3 Installing foot control hanger �������������������������������������� 11

4–4 Mounting the coolant solution hanger post ������������������ 11

4–5 Installing the irrigation tube ��������������������������������������� 12

4–6 Inserting irrigation tube into bag/bottle ������������������������ 13

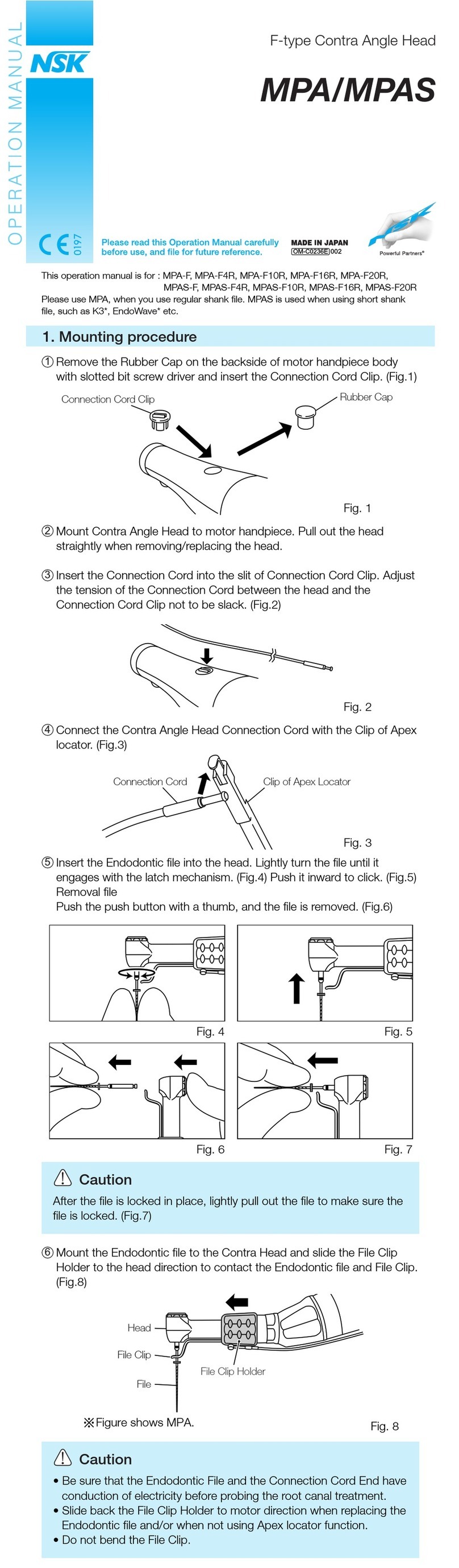

4–7 Connecting the motor cord ����������������������������������������� 14

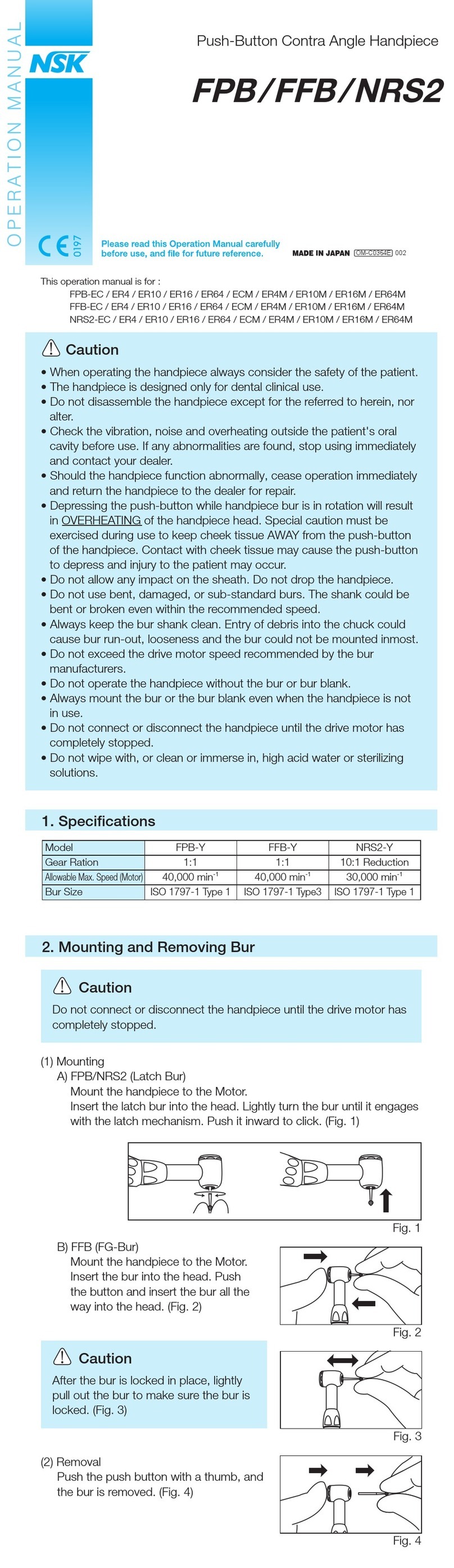

4–8 Connecting the handpiece ����������������������������������������� 14

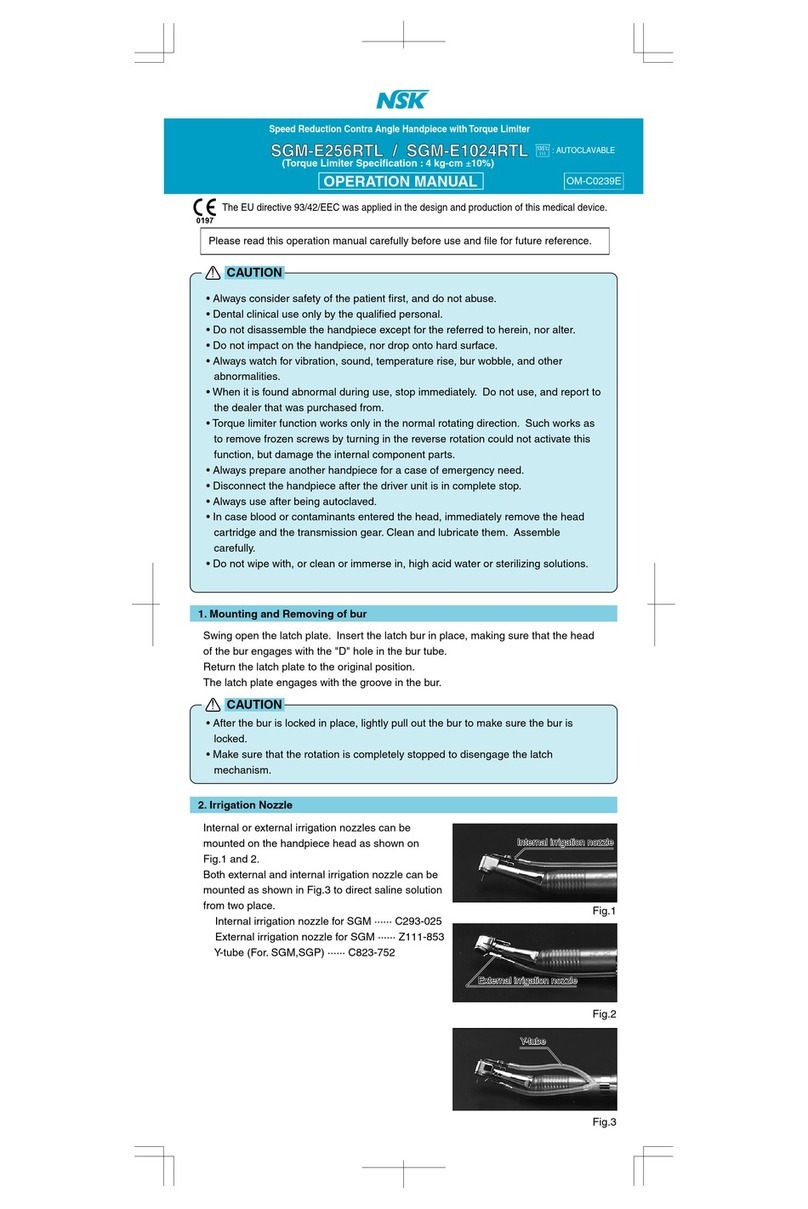

4–9 Irrigation nozzle attachment ��������������������������������������� 15

4–10 Attaching the tube holder ������������������������������������������ 15

4–11 Check before treatment ��������������������������������������������� 15

5. Operation Procedure ....................................... 17

5–1 Calibration function ��������������������������������������������������� 17

5–2 Starting operation ����������������������������������������������������� 20

5–3 Protection circuit ������������������������������������������������������ 21

5–4 Sleep mode �������������������������������������������������������������� 21

5–5 Link function ������������������������������������������������������������ 22

6. Post-use Maintenance .................................... 26

6–1 Preparation for maintenance �������������������������������������� 26

6–2 Cleaning and disinfection ������������������������������������������� 26

6–3 Sterilization �������������������������������������������������������������� 29

6–4 Storage �������������������������������������������������������������������� 29

7. Maintenance .................................................. 30

7–1 Replace the O-ring ���������������������������������������������������� 30

7–2 Periodical maintenance checks ���������������������������������� 30

7–3 Foot control calibration ���������������������������������������������� 31

8. Setting ........................................................... 32

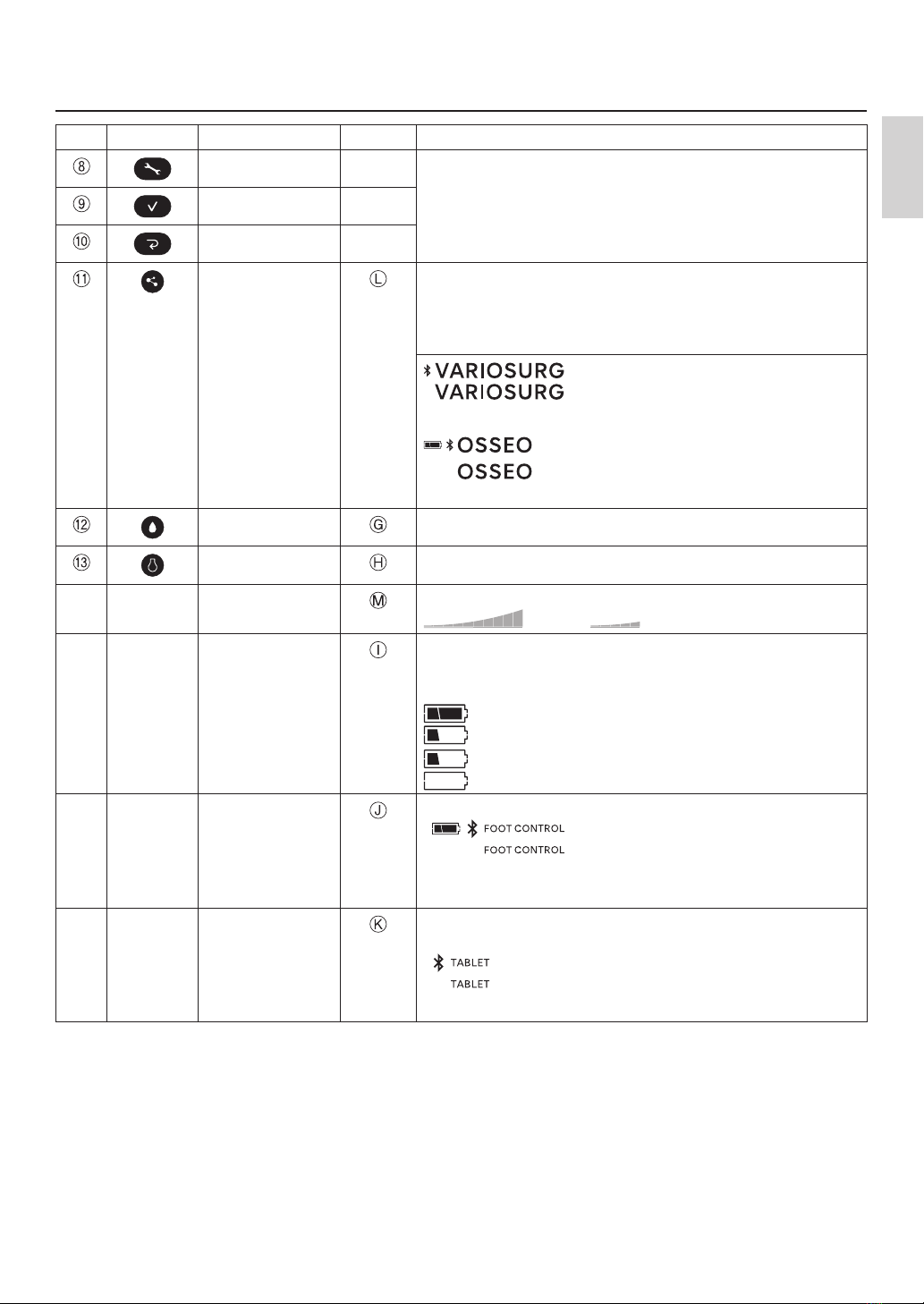

8–1 Setting key ��������������������������������������������������������������� 32

8–2 Implant system ��������������������������������������������������������� 37

8–3 Programming the system operation ����������������������������� 38

9. Troubleshooting .............................................. 40

9–1 Error code ���������������������������������������������������������������� 40

9–2 Problems and solutions ��������������������������������������������� 41

10. Contra Angle Handpieces, Spare Parts and

Optional Parts ................................................ 44

10–1 Contra angle handpieces ������������������������������������������� 44

10–2 Spare parts list ��������������������������������������������������������� 44

10–3 Optional parts list ����������������������������������������������������� 45

10–4 Compatible terminals ������������������������������������������������ 45

11. Specifications ................................................ 46

11–1 Specifications ����������������������������������������������������������� 46

11–2 Bluetooth specifications ��������������������������������������������� 47

11–3 Classification of equipment ���������������������������������������� 47

11–4 Operation principle ���������������������������������������������������� 47

11–5 Warranty ������������������������������������������������������������������ 47

11–6 Disposing of products ������������������������������������������������ 47

11–7 Symbol �������������������������������������������������������������������� 48

11–8 Factory settings (Implant system) �������������������������������� 49

12. EMC Information (Electromagnetic Compatibility

Information) ................................................... 51