5/25/05 i

Table of Contents

Preface

Copyright .........................................................................iii

Document Summary ........................................................iii

Product Support, Documentation and Service.................iii

1 Introduction

General Description ......................................................... 1

Arizona T220UV Specifications ....................................... 2

Physical.................................................................... 2

Performance ............................................................ 2

2 System Requirements

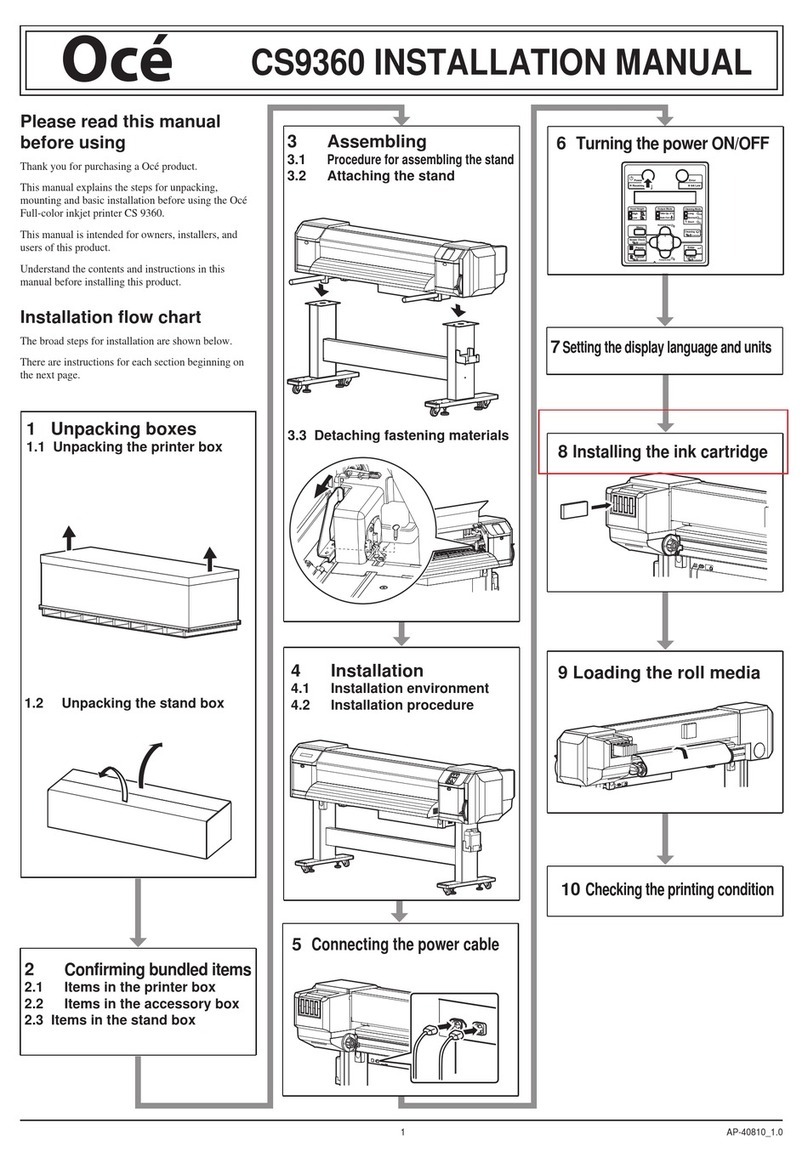

Receiving and Moving the Arizona® T220UV ................. 3

Receiving the Shipping Crates................................. 3

Hallway Requirements ............................................. 5

Space Requirements ............................................... 5

Electrical Requirements................................................... 6

AC Power................................................................. 6

Printer Power Requirements.................................... 6

Vacuum Pump Power Requirements....................... 7

GFI Circuit Breakers ................................................ 8

AC Distribution Circuit.............................................. 8

Grounding ................................................................ 9

Compressed Air Requirement ......................................... 9

Environmental Requirements ........................................ 10

Operating Conditions ............................................. 10

Shock and Vibration............................................... 11

Shipping and Storage ............................................ 11

Safety Information.......................................................... 12

Customer Equipment Requirements.............................. 13

Digital Calipers....................................................... 13

Spectrophotometer ................................................ 13

Host Computer Requirements ............................... 13

Operator Training........................................................... 14

Appendix A Pre-Installation Checklist

Customer Information .................................................... 16

System Requirements Checklist.................................... 17