Ogawa OG8020 Manual

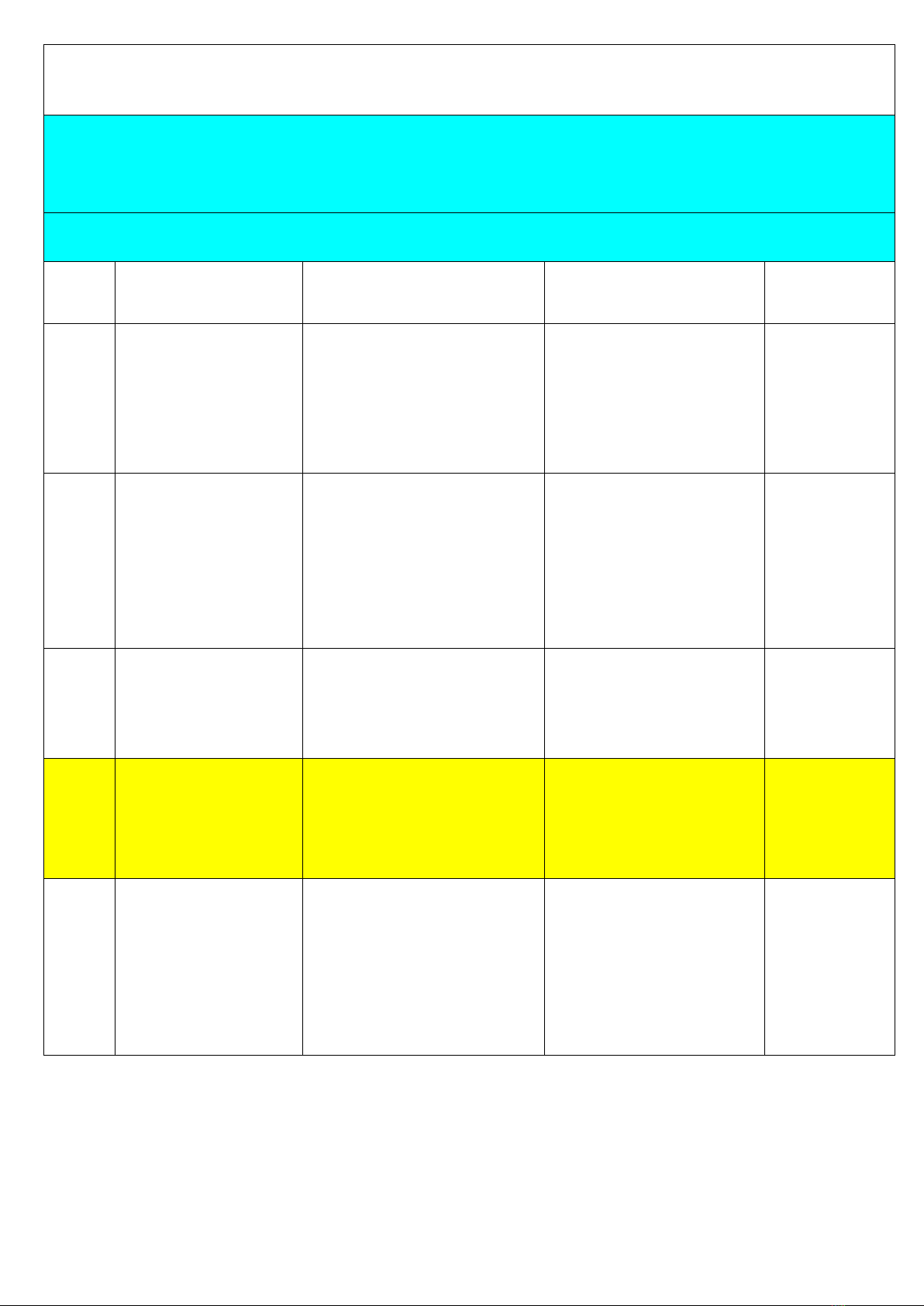

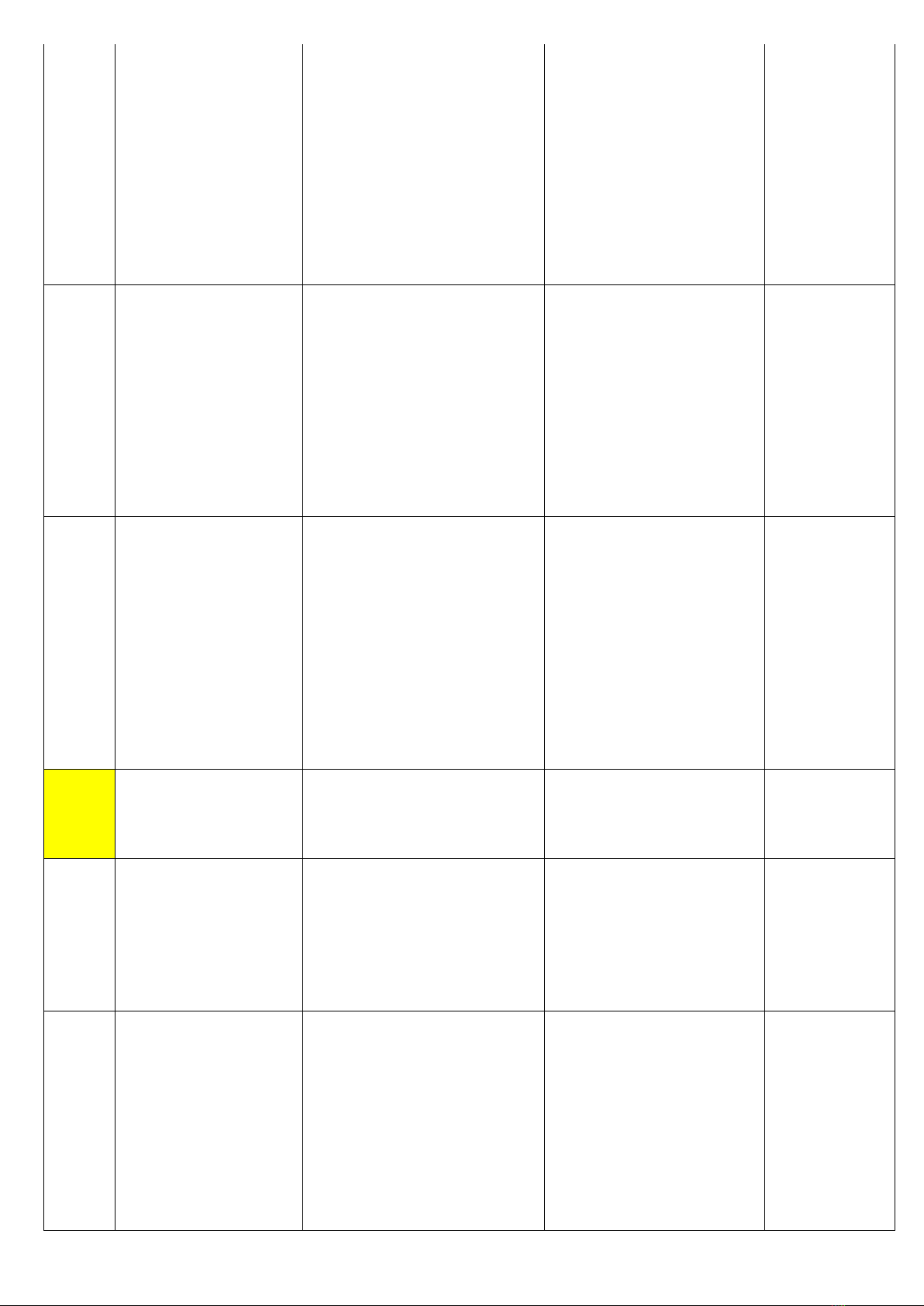

Other Ogawa Massager manuals

Ogawa

Ogawa MyPillow User manual

Ogawa

Ogawa KEVATOUCH OL0359 User manual

Ogawa

Ogawa Mobile Shiatsu LITE OG2015 User manual

Ogawa

Ogawa SMARTVOGUE User manual

Ogawa

Ogawa OGF 8299 User manual

Ogawa

Ogawa mobileseat XE DUO User manual

Ogawa

Ogawa mobile Shiatsu QT User manual

Ogawa

Ogawa EC-802A User manual

Ogawa

Ogawa omknee OGCF2002A User manual

Ogawa

Ogawa estiloLITE PLUS User manual

Ogawa

Ogawa mobile Shiatsu QT User manual

Ogawa

Ogawa MASSGENIUS User manual

Ogawa

Ogawa EZ Wave Lite User manual

Ogawa

Ogawa MY sofa LUXE User manual

Ogawa

Ogawa Tapping Footte User manual

Ogawa

Ogawa iModa PLUS User manual

Ogawa

Ogawa OG5020 User manual

Ogawa

Ogawa BellaX User manual

Ogawa

Ogawa OG 5010 User manual

Ogawa

Ogawa ISPA OF 3006 User manual