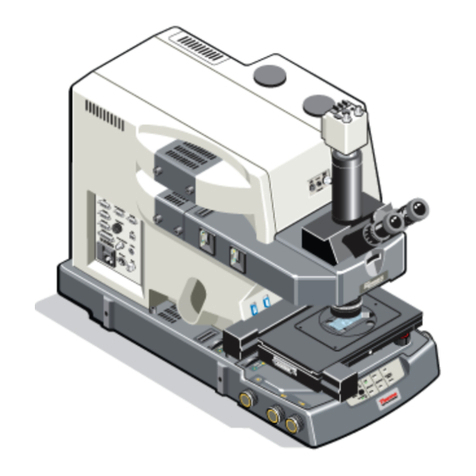

Introduction/Precautions Operation/Maintenance Manual

1. Precautions

Operators must follow the instructions in the Operation/Maintenance Manual. If these instructions are not

followed, safety can not be assured, and malfunctions may occur.

The following 3 types of symbols are used in this Manual to draw operators' attention.

: Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

: Indicates a potentially hazardous situation which, if not avoided, may result in

damage to the product or other property and/or may cause problems.

2. Safety Precautions

1. Always use the power cord provided by Olympus. If no power cord is provided

, please select the power cord by referring to the section “PROPER SELECTION

OF THE POWER SUPPLY CORD” at the end of this chapter. If the proper power cord

is not used, Olympus can no longer warrant the electrical safety performance of

the equipment. Layout the power cord at a sufficient distance from the sources of

heat such as the power supply unit/light source and lamp housing to avoid

contact with these heat sources.

2. Use the device within the scope of the specifications.

3. When you move equipment, notify Olympus distributor.

4. Always Install the product at the location where you can reach the power cord at hand

to disconnect it quickly. In case the abnormality is found with the loader, pull out the

power cord immediately from the back side of the loader.

5. Bundle cables or tubes to the table legs, etc. to prevent your legs from getting caught

in cables or tubes.

6. Be sure to connect the ground terminal of the power cord and that of the power outlet.

Otherwise, the electric safety performance intended by Olympus cannot be assured.

7. Never place a metallic object in the ventilation. This could cause an electrical shock or

malfunction.

8. Maintenance works must be done by well-trained person.

9. When it cleans a broken wafers, it is use with protection gloves etc.

10. In case the vacuum supply is stopped, a risk of dropping the wafer may be caused

during the test. It is recommended to connect the check valve or the buffer tank in

order to maintain the vacuum in case the vacuum supply is stopped. The check valve