SF8P_E2 Sensors_EN_INT02

Please contact your OMRON representative for information

about our complete portfolio.

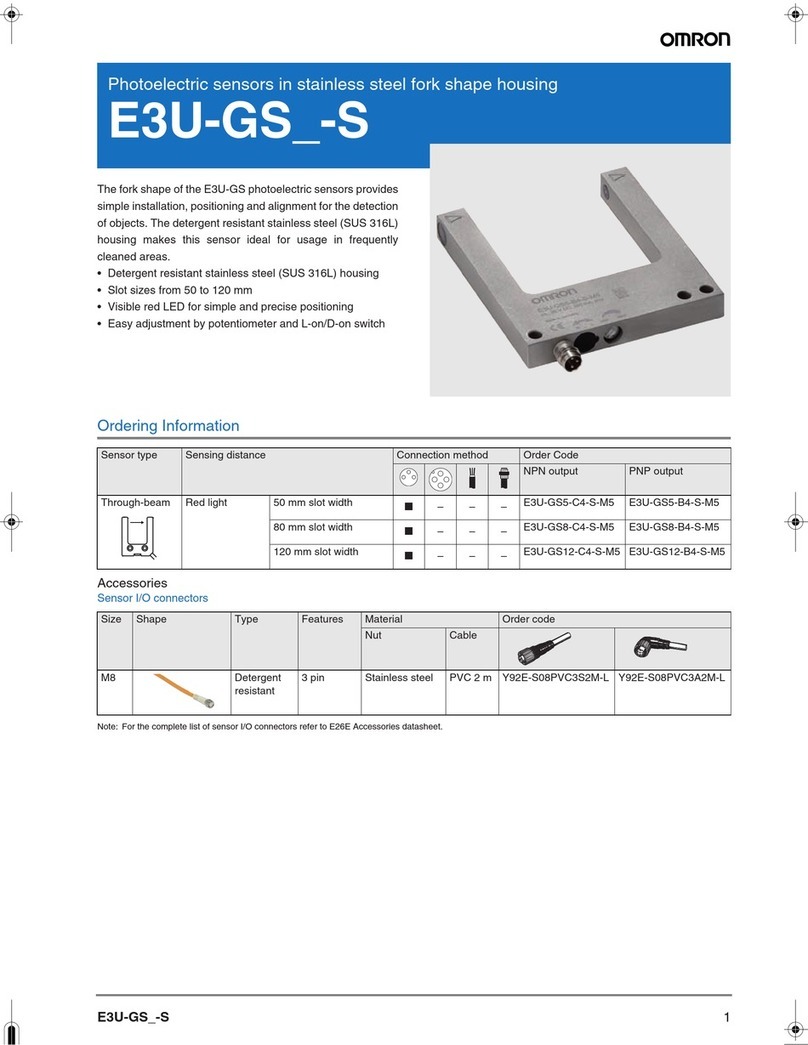

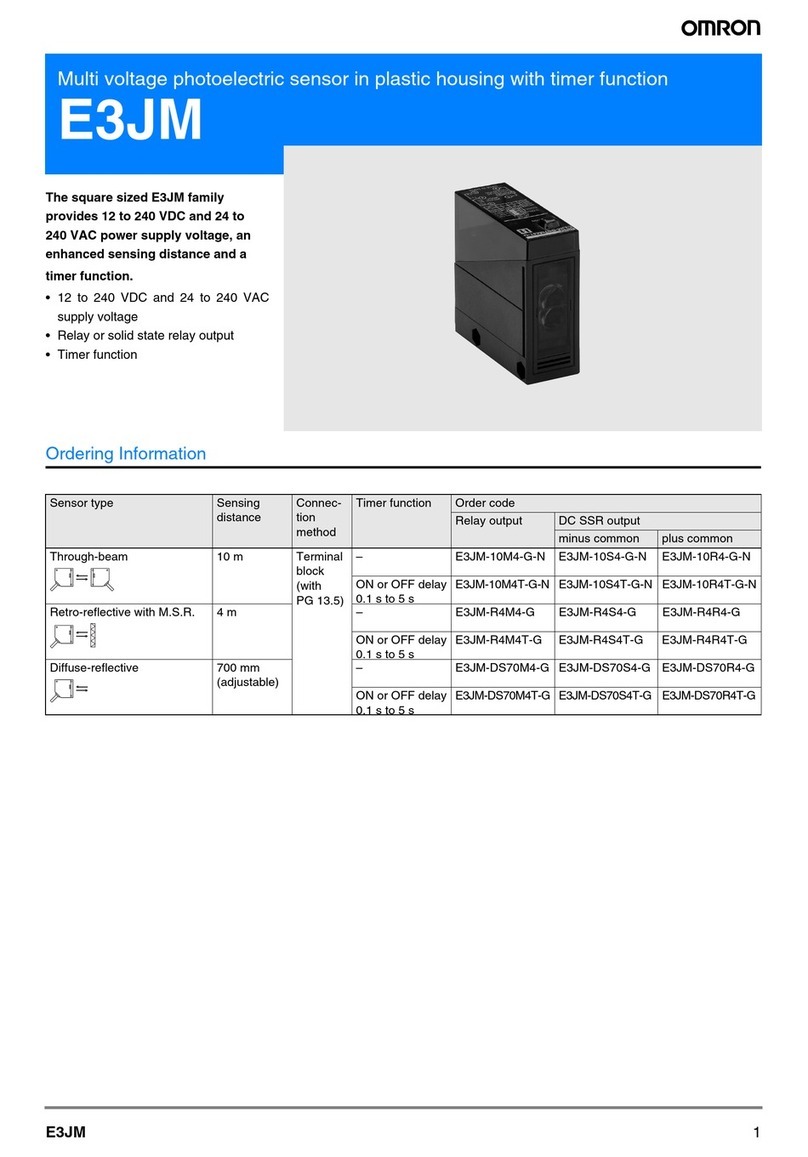

special sizes special shapes special functions

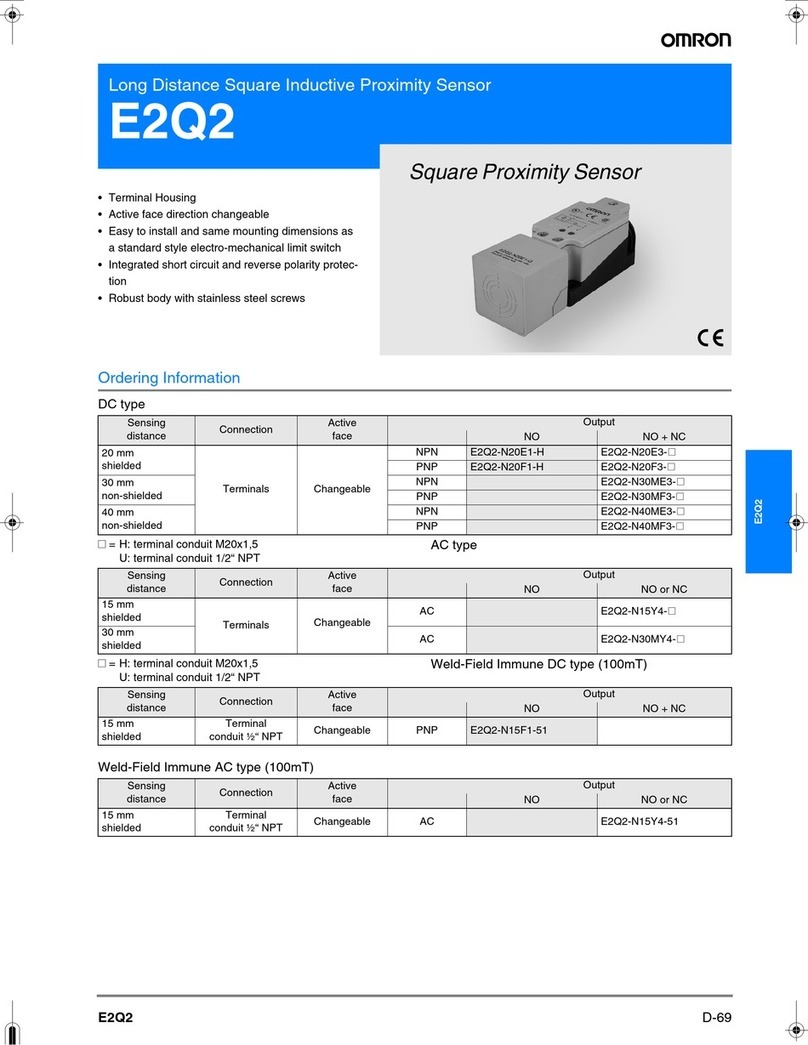

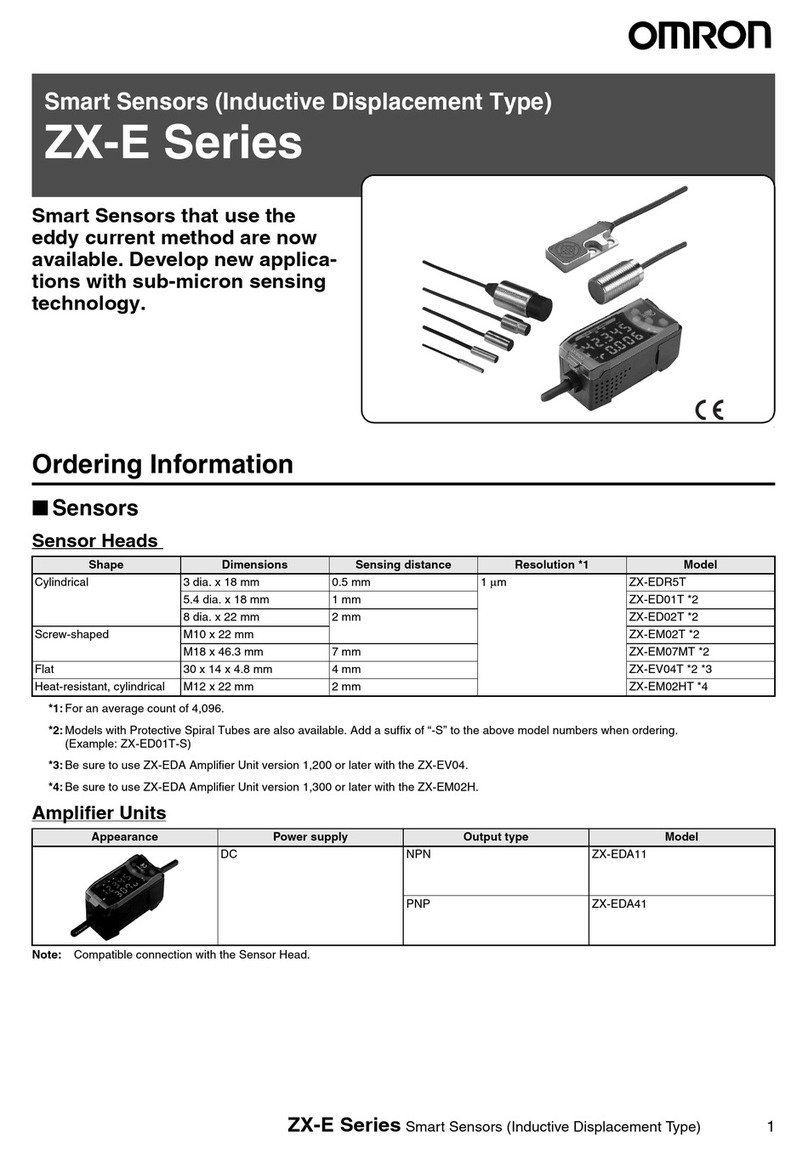

E2EC, E2E small diameter E2S, TL-T, TL-W, E2Q2 ZX-E, E2C, E2EQ, E2FQ, …

Wide range of models available

Austria

Tel: +43 (0) 1 80 19 00

www.omron.at

Belgium

Tel: +32 (0) 2 466 24 80

www.omron.be

Czech Republic

Tel: +420 234 602 602

www.omron-industrial.cz

Denmark

Tel: +45 43 44 00 11

www.omron.dk

Finland

Tel: +358 (0) 207 464 200

www.omron.fi

France

Tel: +33 (0) 1 56 63 70 00

www.omron.fr

Germany

Tel: +49 (0) 2173 680 00

www.omron.de

Hungary

Tel: +36 (0) 1 399 30 50

www.omron.hu

Italy

Tel: +39 02 326 81

www.omron.it

Middle East & Africa

Tel: +31 (0) 23 568 11 00

www.omron-industrial.com

Netherlands

Tel: +31 (0) 23 568 11 00

www.omron.nl

Norway

Tel: +47 (0) 22 65 75 00

www.omron.no

Poland

Tel: +48 (0) 22 645 78 60

www.omron.pl

Portugal

Tel: +351 21 942 94 00

www.omron.pt

Russia

Tel: +7 495 648 94 50

www.omron-industrial.ru

Spain

Tel: +34 913 777 900

www.omron.es

Sweden

Tel: +46 (0) 8 632 35 00

www.omron.se

Switzerland

Tel: +41 (0) 41 748 13 13

www.omron.ch

Turkey

Tel: +90 (0) 216 474 00 40

www.omron.com.tr

United Kingdom

Tel: +44 (0) 870 752 08 61

www.omron.co.uk

More Omron representatives

www.omron-industrial.com

Control Systems

• Programmable logic controllers • Human-machine interfaces • Remote I/O

Motion & Drives

• Motion controllers • Servo systems • Inverters

Control Components

• Temperature controllers • Power supplies • Timers • Counters • Programmable relays

• Digital panel indicators • Electromechanical relays • Monitoring products • Solid-state relays

• Limit switches • Pushbutton switches • Low voltage switch gear

Sensing & Safety

• Photoelectric sensors • Inductive sensors • Capacitive & pressure sensors • Cable connectors

• Displacement & width-measuring sensors • Vision systems • Safety networks • Safety sensors

• Safety units/relay units • Safety door/guard lock switches

Authorised Distributor:

Although we strive for perfection, Omron Europe BV and/or its subsidiary and affiliated companies do not warrant

or make any representations regarding the correctness or completeness of the information described in this document.

We reserve the right to make any changes at any time without prior notice.

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD, Hoofddorp, The Netherlands. Tel: +31 (0) 23 568 13 00 Fax: +31 (0) 23 568 13 88 www.omron-industrial.com