D-74 Inductive Sensors

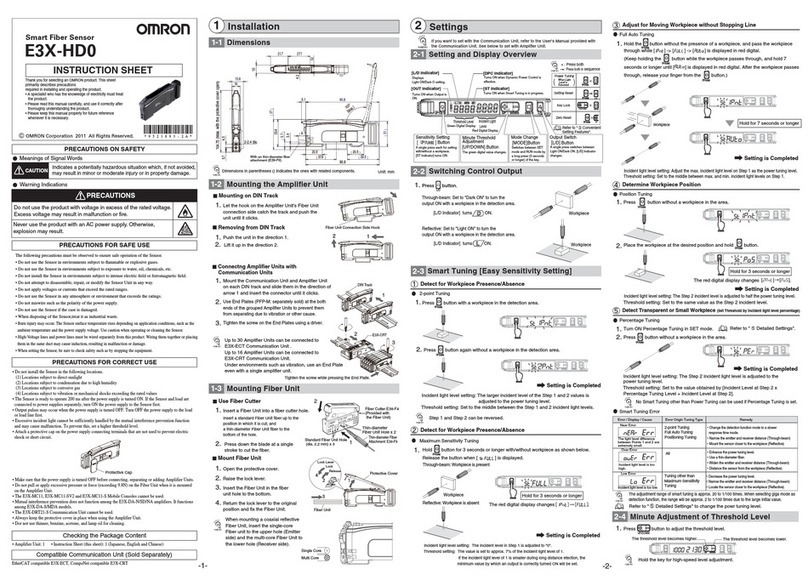

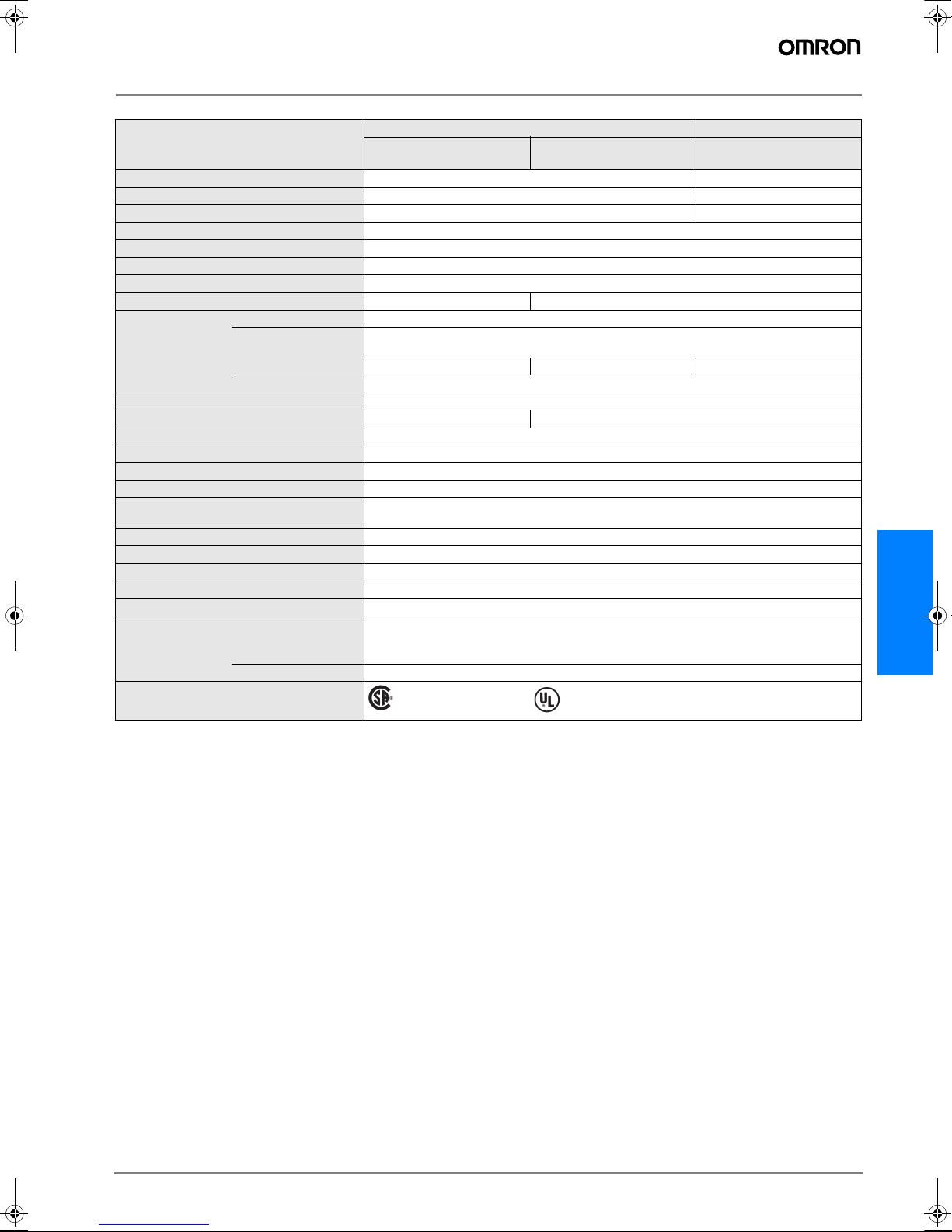

Connection

DC type

AC type

Connection type Method Description

AND

(serial connection)

The Sensors connected together must satisfy the following conditions:

iL+ (N-1) x i ≤Upper-limit of control output of each Sensor

VS- N x VR≥Load operating voltage

N = No. of Sensors

VR= Residual voltage of each Sensor

VS= Supply voltage

i = Current consumption of the Sensor

iL= Load current

If the MY Relay, which operate at 24 VDC, is used as a load for example,

a maximum of two Proximity Sensors can be connected to the load.

OR

(parallel connec-

tion)

A minimum of three Sensors with current outputs can be connected in

parallel. The number of Sensors connected in parallel varies with the

Proximity Sensor model.

Connection type Method Description

AND

(serial connection)

If 100 or 200 VAC is imposed on the Proximity Sensors, VL(i.e., the volt-

age imposed on the load) will be obtained from the following.

VL=VS- (residual voltage x no. of Proximity Sensors) (V)

Therefore, if VLis lower than the load operating voltage, the load will not

operate.

A maximum of three Proximity Sensors can be connected in series pro-

vided that the supply voltage is 100 V minimum.

OR

(parallel connec-

tion)

In principle, more than two Proximity Sensors cannot be connected in

parallel.

Provided that Proximity Sensor A does not operate with Proximity Sen-

sor B simultaneously and there is no need to keep the load operating

continuously, the Proximity Sensors can be connected in parallel. In this

case, however, due to the total leakage current of the Proximity Sensors,

the load may not reset properly.

It is not possible to keep the load operating continuously with Proximity

Sensors A and B in simultaneous operation to sense sensing objects due

to the following reason.

When Proximity Sensor A is ON, the voltage imposed on Proximity Sen-

sor A will drop to approximately 10 V and the load current flows into Prox-

imity Sensor A, and when one of the sensing objects is close to Proximity

Sensor B, Proximity Sensor B will not operate because the voltage im-

posed on Proximity Sensor B is 10 V, which is too low.

When Proximity Sensor A is OFF, the voltage imposed on Proximity Sen-

sor B will reach the supply voltage and Proximity Sensor B will be ON.

Then, Proximity Sensor A as well as Proximity Sensor B will be OFF for

approximately 10 ms, which resets the load for an instant. To prevent the

instantaneous resetting of the load, use a relay as shown on the left.

F502-EN2-04.book Seite 74 Dienstag, 26. Juli 2005 5:48 17