Lock

Slider

Cover seal

Lower the lever.

PFP-M

Vertically: OK Horizontally: Not OK

⑥

⑤

SW2

SW1

ERROR

OCC

SD/RD

READY

CN1

G3ZA

B1

B2

B3

B4

B5

B6

B7

B8

B9

OUT2

OUT1

ch2

DC12V

DC12V

TC

+

+

+

–

–

A

B

B

Voltage

output

Voltage

output

V

mA

+

–

+

ch1

TC

+

–

A

B

B

V

mA

+

–

+

A1

A2

A3

A4

A5

A6

A7

A8

A9

OUT4

OUT3

ch4

DC12V

DC12V

TC

+

+

+

–

–

A

B

B

V

mA

+

–

+

ch3

TC

+

–

A

B

B

V

mA

+

–

+

Analog

input

Pt

input

TC

input

B1

B2

B3

B4

B5

B6

B7

B8

B9

OUT2

OUT1

ch2

DC12V

DC12V

TC

+

+

+

–

–

A

B

B

V

mA

+

–

+

ch1

TC

+

–

A

B

B

V

mA

+

–

+

A1

A2

A3

A4

A5

A6

A7

A8

A9

OUT4

OUT3

CT2

CT1

EV2

COM

EV1

※

B1

B2

B3

B4

B5

B6

B7

B8

B9

OUT2

OUT1

ch2

4-20/0-20mA DC

4-20/0-20mA DC

TC

+

+

+

–

–

A

B

B

V

mA

+

–

+

ch1

TC

+

–

A

B

B

V

mA

+

–

+

A1

A2

A3

A4

A5

A6

A7

A8

A9

OUT4

OUT3

EV2

COM

EV1

※

* Cannot be used for the Gradient Temperature Control Model (EJ1G).

1

2

3

4

5

6

7

8

9

Port A

Port A

Port A (Connector)

RS-485

A(–)

B(+)

Port B

Port B

RS-485

A(–)

B(+)

B(+)

A(–)

SUB2

COM

SUB1

COM

B(+)

A(–)

+

–

DC24V

DC24V

–

+

Input

power supply

SUB2

SUB1

COM

Both of these ports

cannot be used at

the same time.

Donotusethisport

whenusingan

AdvancedUnit.

DO NOT USE

1

2

3

4

5

6

7

8

9

10

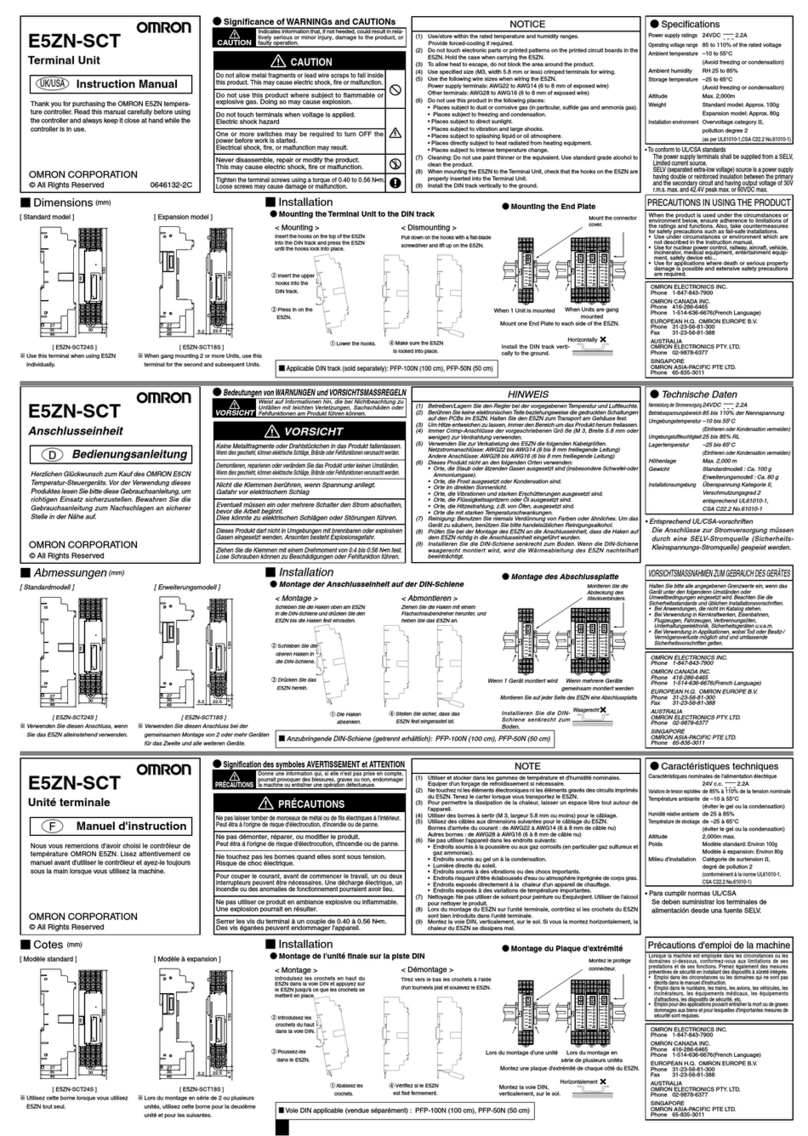

Operation indicator Pin 6 of SW2 = OFF

Pin 6 of SW2 = ON (See note 2.)

PWR/1

(green) Lit when power is supplied.

Lit when output 1 is ON.

RUN/2 (green)(See note 1.)

Lit during operation. Lit when output 2 is ON.

ERR/3 (red)

Flashes or lights when an error occurs.

Lit when output 3 is ON.

ALM/4 (red)

Lights when an alarm occurs.

Lit when output 4 is ON.

COM1

(orange)

Flashes during communications on End Unit port A.

COM2

(orange)

Flashes during communications on End Unit port B.

COM3

(orange)

Flashes during communications with the G3ZA.

Note 1.

Functions only on Modular Temperature Control Models (EJ1N).

Note 2. Functions only on Basic Units of Modular Temperature

Controller models (EJ1N).

Indicatesa potentially hazardoussituationwhich,if

notavoided,islikelytoresultinminorormoderate

injury or property damage. Read this manual

carefullybeforeusingtheproduct.

CAUTION

EJ1

Temperature controller

1)

The product is designed for indoor use only. Do not use the product outdoors or in any of the following locations.

• Places directly subject to heat radiated from heating equipment.

• Places subject to splashing liquid or oil atmosphere.

• Places subject to direct sunlight.

• Places subject to dust or corrosive gas (in particular, sulfide gas or ammonia gas).

• Places subject to intense temperature change.

• Places subject to icing or condensation.

• Places subject to vibration or strong shocks.

2)

Use and store the product within the rated temperature and humidity ranges. Provide forced-cooling if required.

3)

To allow heat to escape, do not block the area around the product. Do not block the ventilation holes on the product.

4) Be sure to wire properly with correct polarity of terminals.

5) Use specified size (M3, width 5.8 mm or less) crimped terminals for wiring. To connect bare wires to the

terminal block, use copper braided or solid wires with a gage of AWG22 to AWG14 (equal to cross-

sectional area of 0.326 to 2.081 mm

2

) for power supply lines and a gage of AWG28 to AWG16 (equal to

cross-sectional area of 0.081 to 1.309 mm

2

). (The stripping length is 6 to 8 mm.)

Up to two wires of same size and type, or two crimped terminals can be inserted into a single terminal.

6) Do not wire terminals that do not have an identified use.

7) Allow as much space as possible between the product and devices that generate a powerful high-

frequency or surge. Separate the high-voltage or large-current power lines from other lines, and avoid

parallel or common wiring with the power lines when you are wiring to the terminals.

8) Use the product within the rated load and power supply.

9) Make sure that the rated voltage is attained within 2 seconds of turning ON the power.

10) Make sure that the product has 30 minutes or more to warm up after turning ON the power before

starting actual control operations to ensure the correct temperature display.

11) The switch or circuit breaker must be within easy reach of the operator, and must be marked as a

disconnecting means for this unit.

12) Do not use paint thinner or similar chemical to clean with. Use standard grade alcohol.

13) Design the system (e.g., the control panel) allowing leeway for the delay required before product outputs

are valid after turning ON power to the product.

14) Never touch the electronic components, connectors, or patterns on product boards with your bare

hands. Always hold the product by the case. Inappropriately handling the product may occassionally

damage internal components due to static electricity.

15) Use a switch, relay, or other device with contacts to turn OFF the power supply quickly. Gradually

lowering the voltage of the power supply may result in incorrect outputs or memory errors.

16) Do not touch the electronic components with your hands or subject them to shock when removing the

terminal block.

17) Connect only the specified number of products in only a specified configuration.

18) Mount the product to a DIN Rail mounted vertically to the ground.

19) Always turn OFF the power supply before wiring the product, replacing the product, or changing the

product configuration.

20) Attach the enclosed cover seal to the connector opening on the left end product during installation.

21) Do not use port B on the End Units when using port C on Advanced Units.

Precautions for Safe Use

●Key to Warning Symbols

Instruction Manual

Thank you for purchasing the OMRON Product. To

ensure the safe application of the Product, only a

professional with an understanding of electricity and

electric devices must handle it. Read this manual

carefully before using the Product and always keep it

close at hand when the

Product is in use.

Suitability for Use

CAUTION

Do not touch the terminals while power is being supplied.

Doing so may occasionally result in minor injury due to electric shock.

Use a power supply that complies with the reinforced insulation

specified in IEC 60664 for the EJ1 external power supply or the power

supply connected to the EJ1. If non-compliant power supplies are

used, electric shock may occasionally result in minor injury.

Do not allow pieces of metal, wire clippings, or fine metallic shavings

or filings from installation to enter the product. Doing so may

occasionally result in electric shock, fire, or malfunction.

Do not use the product where subject to flammable or explosive gas.

Otherwise, minor injury from explosion may occasionally occur.

Never disassemble, modify, or repair the product or touch any of the

internal parts.

Minor electric shock, fire, or malfunction may occasionally occur.

Tighten the terminal screws to between 0.40 and 0.56 N・m. Loose

screws may occasionally result in fire.

Set the parameters of the product so that they are suitable for the

system being controlled. If they are not suitable, unexpected operation

may occasionally result in property damage or accidents.

A malfunction in the product may occasionally make control operations

impossible or prevent alarm outputs, resulting in property damage. To

maintain safety in the event of malfunction of the product, take

appropriate safety measures, such as installing a monitoring

device on a separate line.

Gradient temperature control controls the average temperature for

multiple channels. Therefore, if a heater burnout occurs during gradient

temperature control, the temperature for that channel will drop and the

temperature for the other channels will rise, which may occasionally result

in property damage. During gradient temperature control, provide safety

measures using information such as using the heater burnout alarm and

temperature data for each channel.

EN

●Warning Symbols

Safety Precautions

OMRON CORPORATION

©All Rights Reserved

1132575-5A

EJ8

OMRON shall not be responsible for conformity with any standards, codes, or regulations that

apply to the combination of the products in the customer's application or use of the product.

Take all necessary steps to determine the suitability of the product for the systems, machines,

and equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO

LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN

DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

See also product catalog for Warranty and Limitation of Liability.

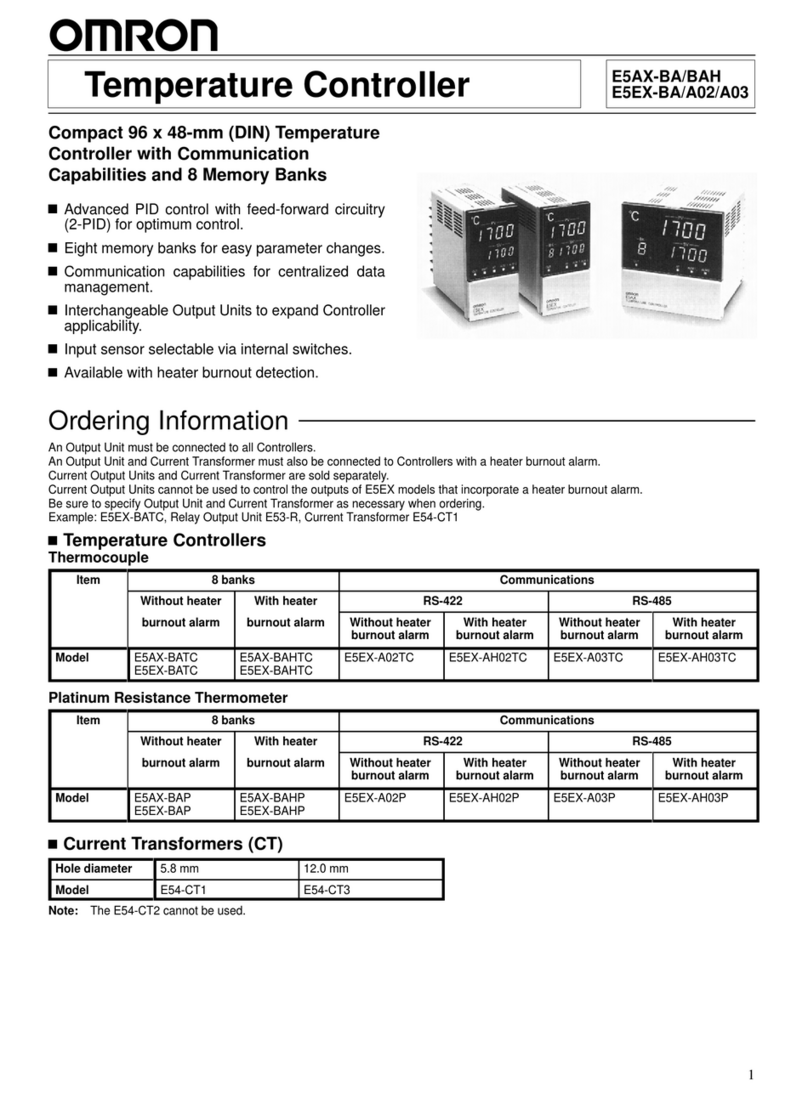

●Specifications

Power supply voltage

24 VDC 5A (at max. DC load)

Operating voltage range

85% to 110% of the rated voltage

Power consumption

Basic Unit: TC4 5 W max. (at max. DC load)

TC2 4 W max. (at max. DC load)

Indication accuracy

Thermocouple, Platinum Resistance Thermometer

Input: (±0.5% of indication value or ±1˚C,

which is greater) ±1 digit max.

Analog Input:

(±0.5% F/S) ±1 digit max.

CT Input:

(±5% F/S) ±1 digit max.

Control output Voltage output: 12 VDC, 21 mA max.

Current output: 0 to 20 mA DC, 4 to 20 mA DC

load of 500 Ωmax.

Transistor output: 30 VDC, 100 mA max.

Auxiliary output Transistor output: 30 VDC, 50 mA max.

Control method ON/OFF or advanced PID

Ambient temperature

Operating –10 to 55˚C

*

Storage –25 to 65˚C

(with no freezing or condensation)

* Ambient Temperature according to

UL61010C-1: –10 to 40˚C

Ambient humidity Operating RH 25% to 85%

Storage RH 25% to 85%

Inrush current (POWER)

Individual Unit: 15 A max.

Weight End Unit: 70 g

Basic Unit: 180 g

Degree of protection Rear case, End Unit case: IP20

Terminal section: IP00

Installation environment

Overvoltage category II, pollution degree 2

(as per IEC 61010-1)

Altitude 2,000 m max.

Event inputs Output current: Approx. 4 mA

Contact input ON: 1 kΩmax.,

OFF:100 kΩmin.

No-contact input ON: Residual voltage of 1.5 V max.,

OFF: Leakage current of 0.1 mA max.

Max. heater current Single-phase, 100 A (AC)

Memory protection EEPROM (non-volatile memory)

(Number of write operations: 100,000)

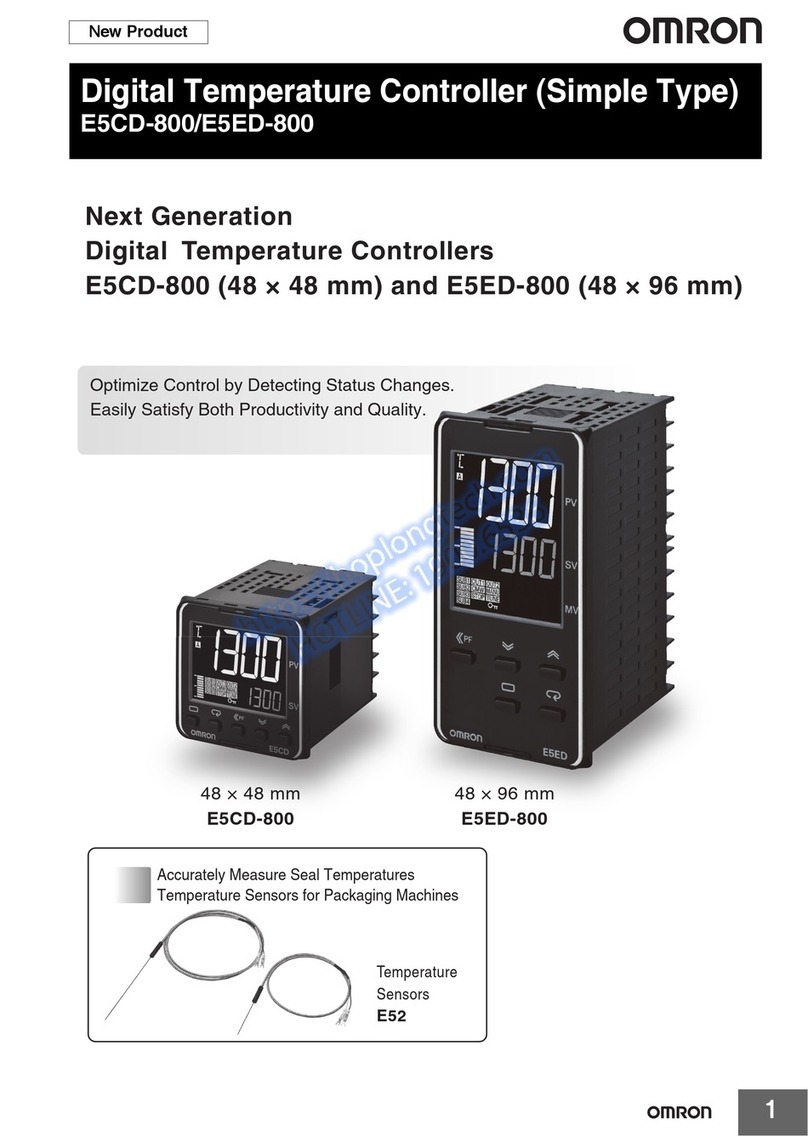

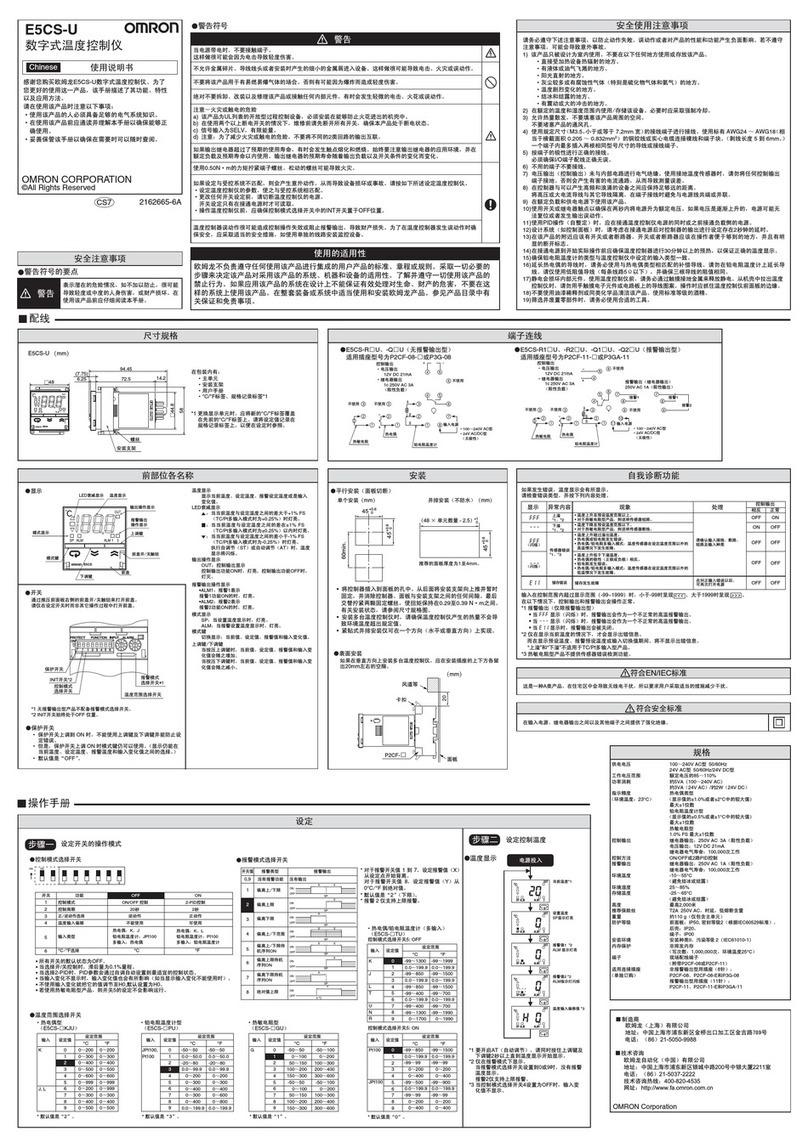

■Wiring

●Dimensions (mm)

■Display

●Names of Parts on Front Panel

■Specification Settings

●Switch Operation

●Operation Indicators

●Installation

• Connecting Units

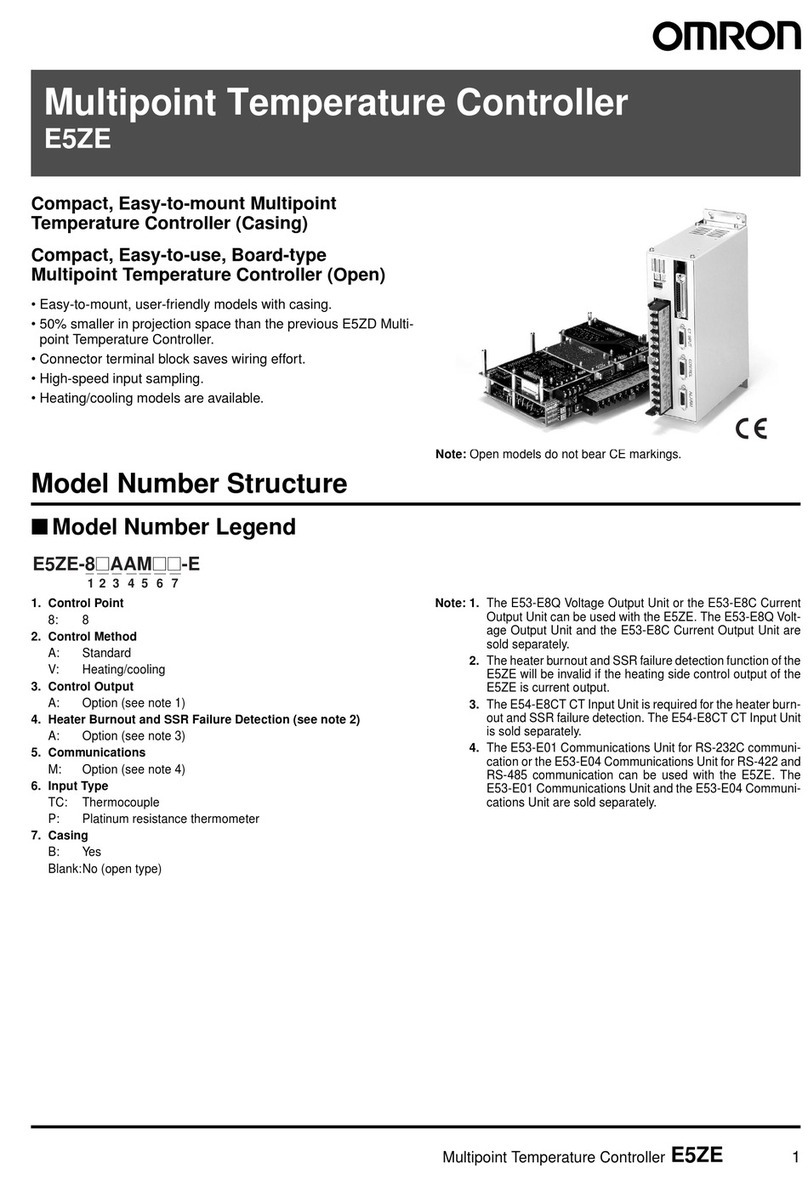

[EJ1□-TC: Basic Unit] [EJ1C-EDU: End Unit]

• Mounting to the DIN Rail

• Wiring Procedure for Screw-Less Clamp Terminals

• Removing the Terminal Block

1. Align the connector and

connect the Units to

each other. Connect and

End Unit to the Unit on

the right end. (Up to 16

Units can be connected

side by side.)

<Mounting>

Insert the hooks on the top of the EJ1 into the DIN Rail

and press the EJ1 until the hooks lock into place.

②Insert the upper hooks

into the DIN Rail.

③Press in

on the

EJ1. ①Lower the

hooks. ④Make sure the

EJ1 is locked

into place.

Flat-blade Screwdriver

There are two holes for each terminal.

The hole on the right is the operating

hole; the hole on the left is the wire hole.

Insert a flat-blade screwdriver with a

width of 2.5 mm into the operating hold

and then wiring into the wire hole. The

wire will be clamped when the

screwdriver is removed.

Use crimp terminals for wiring that match

the cross-sectional area of the wiring

material.

• We recommend the crimp terminals:

Weidmuller H-sleeve series

●To Conform to UL/CSA Standards

•

The power supply terminals must be supplied from a

SELV, limited-current source.

A SELV (safety extra-low voltage) source is a power supply

having double or reinforced insulation between the primary

and the secondary circuits and having an output voltage of

30 V r.m.s. max. and 42.4 V peak max. or 60 VDC max.

•

This is a class A product. In residential environment areas

it may cause radio interference, in which case the user

may be required to take adequate measures to reduce

interference.

●Functional insulation is provided between the power supply,

input, output, and power supply terminals. If reinforced or

double insulation is required, use a power supply that

complies with the reinforced or double insulation standards

specified in IEC 60664 for the EJ1 external power supply

and for the power supply connected to the EJ1.

Connect the G3ZA

harness to the CN1

connector on the

bottom of the Unit.

Connect the black line

with a white stripe to

terminal 7 on the G3ZA

and the black line with

no stripe to terminal 8.

<Dismounting>

Pull down on the

hooks with a flat-blade

screwdriver and lift up

on the EJ1.

Mount one End Plate to each

side of the EJ1 (PFP-M End

Plates are included with the

End Unit).

To mount an End Plate, hook

the bottom of the End Plate on

the bottom of the DIN Rail ⑤,

place the top of the End Plate

on the DIN Rail ⑥, and then

pull down on the End Plate.

Tighten the screw on the End

Plate to secure it.

2.

Slide the yellow sliders on the

tops and bottoms of the Units

until they click into place.

•Check that the EJ1 is turned OFF before operating

the switches. Settings are valid only when power is

supplied.

•Set the switches with a small flat-blade screwdriver.

Do not set the switches midway between settings.

•SW1 is set to 1 and SW2 pins are all set to OFF in the

default settings.

●Setting the Unit Number

●Setting SW2

SW1 and SW2 can be used together to set the unit number to between 00 and 63.

The factory setting is unit number 01.

3. Attach the cover seal to

the connector on the Unit

on the left end.

1. Press down the

terminal block

levers.

2. Pull out the

terminal

block.

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

SW1

SW2

In the pack: • Basic Unit

• Instruction manual

In the pack: • End Unit

• Instruction manual

• End Plate

• Cover seal

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg, IL 60173-5302 U.S.A

Phone 1-847-843-7900

Telephone Consultation 1-800-55-OMRON

FAX 1-847-843-7787

OMRON EUROPE B.V.

Wegalaan 67-69 P.O. BOX 13 2130 AA Hoofddorp The

Netherlands

Phone 31-23-56-81-300

FAX 31-23-56-81-388

OMRON ASIA PACIFIC PTE LTD

83 Clemenceau Avenue, #11-01 UE Square, Singapore

239920

Phone 65-6-835-3011

FAX 65-6-835-2711

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, Kyoto 600-8530 JAPAN

For detailed operating instructions, please refer to the EJ1

Modular Temperature Controller User's Manual (Cat. No.

H142) or the EJ1 Modular Temperature Controller

(Gradient Temperature Control Model) User's Manual (Cat.

No. H143).

Install the DIN Rail vertically

to the ground.

* Do not connect an End Unit directly to an Advanced Unit.

* Always connect an End Unit to the right side of a Basic Unit.

* This Unit cannot be connected to the CJ1 Series.

* Use the EJ1G-□□ in the configuration when performing gradient temperature control, and use the EJ1N-□□

when not performing gradient temperature control.

* When removing the terminal block and replacing the Unit, make sure that the new Unit matches the original Unit.

■Applicable DIN Rail (sold

separately):

PFP-100N (100 cm), PFP-50N

(50 cm)

Precautions for Correct Use

EJ1C-CBLA050

(sold separately)

Length of cable: 5m

Set SW2 to 3 (57.6

kbps).

●Connections

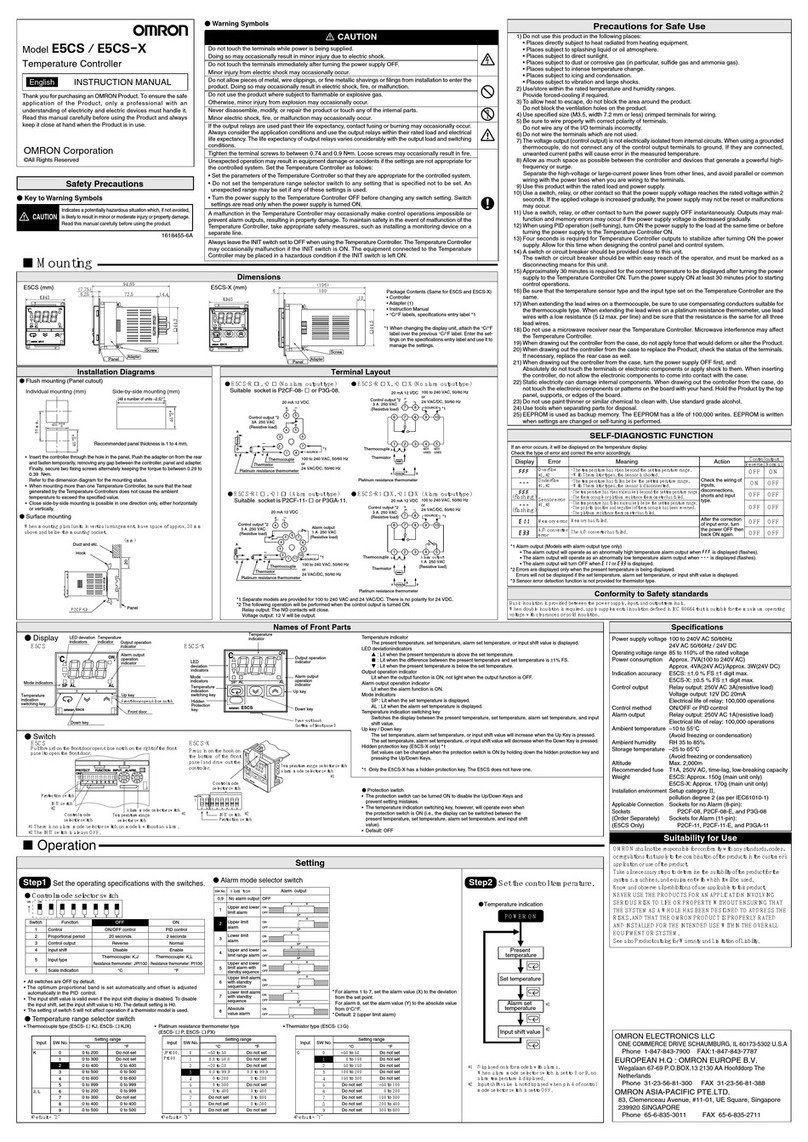

• EJ1□-TC4□-□□□□ • EJ1□-TC2□-Q□□□ • EJ1□-TC2□-C□□□ • EJ1C-EDUA-□FLK

• EJ1C-EDUC-□FLK

* Terminals A10 and B10 of the screw-less clamp terminals are not used.

* Port A (Connector) is used only to connect the Temperature Controller to a computer when using the Setup Tool.

E58-CIFQ1 USB-Serial Conversion Cable is required for the connection. (Do not use the product with the Cable left permanently

connected.) Refer to the Instruction Manual provided with the USB-Serial Conversion Cable for details on connection methods.

* When wiring a voltage input, be sure to connect the correct terminals. Incorrect wiring may cause EJ1 failure.

• Connecting to the G3ZA (EJ1□-TC□□-□□□□)

• Refer to the G3ZA Instruction Manual for wiring

methods.

SW2

Pin 3

Pins

4 and 5

Pin 6

Pin 7

Pin 8

Description

Set to ON when using the Modbus communications protocol for port B.

OFF: The setting for port B communications protocol is used.

ON: Modbus is used.

Set the baud rate for port B.

4 = OFF, 5= OFF: Use port B baud rate setting (default: 9.6 kbps).

4 = ON, 5= OFF: 19.2 kbps

4 = OFF, 5= ON: 38.4 kbps

4 = ON, 5= ON: 115.2 kbps

Set to ON to display the output status on the operation indicators.

OFF: The operation status is displayed (PWR, RUN, ERR, and ALM).

ON: The output status is displayed (outputs 1, 2, 3, and 4).

Note: Normally keep this pin set to OFF so that the operation status

can be checked.

Set to ON when using the G3ZA.

Used when using an Advanced Unit and distributed installation.

(Refer to the User's Manual for details.)