4105260 R. 12/21

Alentec & Orion AB · Grustagsvägen 4 · SE-138 40 · ÄLTA · Sweden · +8 747 67 00 · www.alentec.com

2021_12_15-12:00

ENEN

In this document you will find warnings and cautions for installation, use and maintenance of the pumps.

Here’s the meaning of symbols you may find in this document and general warnings that you should keep in mind.

WARNING: This symbol aware that there is a danger of serious bodily injury or death if you ignore the warning described.

CAUTION: This symbol aware that there is a danger of personal injury or property damage if you ignore the caution described.

• This equipment is for professional use only.

• Do not degrade the integrity of the equipment. Use only original

replacement components from ALENTEC & ORION AB

• Fluids not suitable for the pump can cause damage to the pump unit

and involve risk of serious personal injury. Always consult ALENTEC &

ORION AB if you have any questions about the compatibility within the

fluids and the pump materials, including elastomers.

• Install and use the pump according to all local and national regulations

and abide all health and safety laws or legislation.

• The pump can produce fluid pressures equal to the air supply pressure.

Do not exceed the maximum allowable pressure of 120 psi (8 bar) air

supply. The total hydraulic pressure (differential pressure + system)

should never exceed 120 psi (8 bar).

• Never use a pump that leaks, that is damaged, that is corroded or

otherwise it may lack the capacity to contain the fluid.

• Frequently check that the bolts on the diaphragm cover of the pump

are torqued correctly.

• Do not use a model with aluminium wetted surfaces to pump fluids for

human consumption, there is a possibility of trace contamination of lead.

• Danger of explosion if used 1,1,1-trichloroethane, methylene chloride

or other halogenated hydrocarbon solvents with aluminium wetted

materials. It could cause serious injury and property damage.

• Inside the pump, diaphragms separate the fluid that is being pumped

from the air supply. If a diaphragm breaks, the fluid can leak out of the

air exhaust and contaminate the environment.

• When handling hazardous fluids, always route the air exhaust into a

suitable container and locate it in a safe place. (Optional conection

system at customer’s request. Not supplied with the unit).

• When the fluid source level is situated higher than the pump, (flooded

suction), the outlet tank must be at a higher level than the product to prevent

spills.

• For pumps handling hazardous fluids that are a danger to humans or

to the environment, install a suitable container surrounding the pump

to prevent any leaks or spills.

• Ensure that the operators of this equipment are trained on the

operation and limitations. Use safety equipment as safety goggles or

other equipment required.

WARNING: CAREFULLY READ THE INSTRUCTIONS AND WARNINGS BEFORE OPERATING THE EQUIPMENT!

WARNINGS AND CAUTIONS

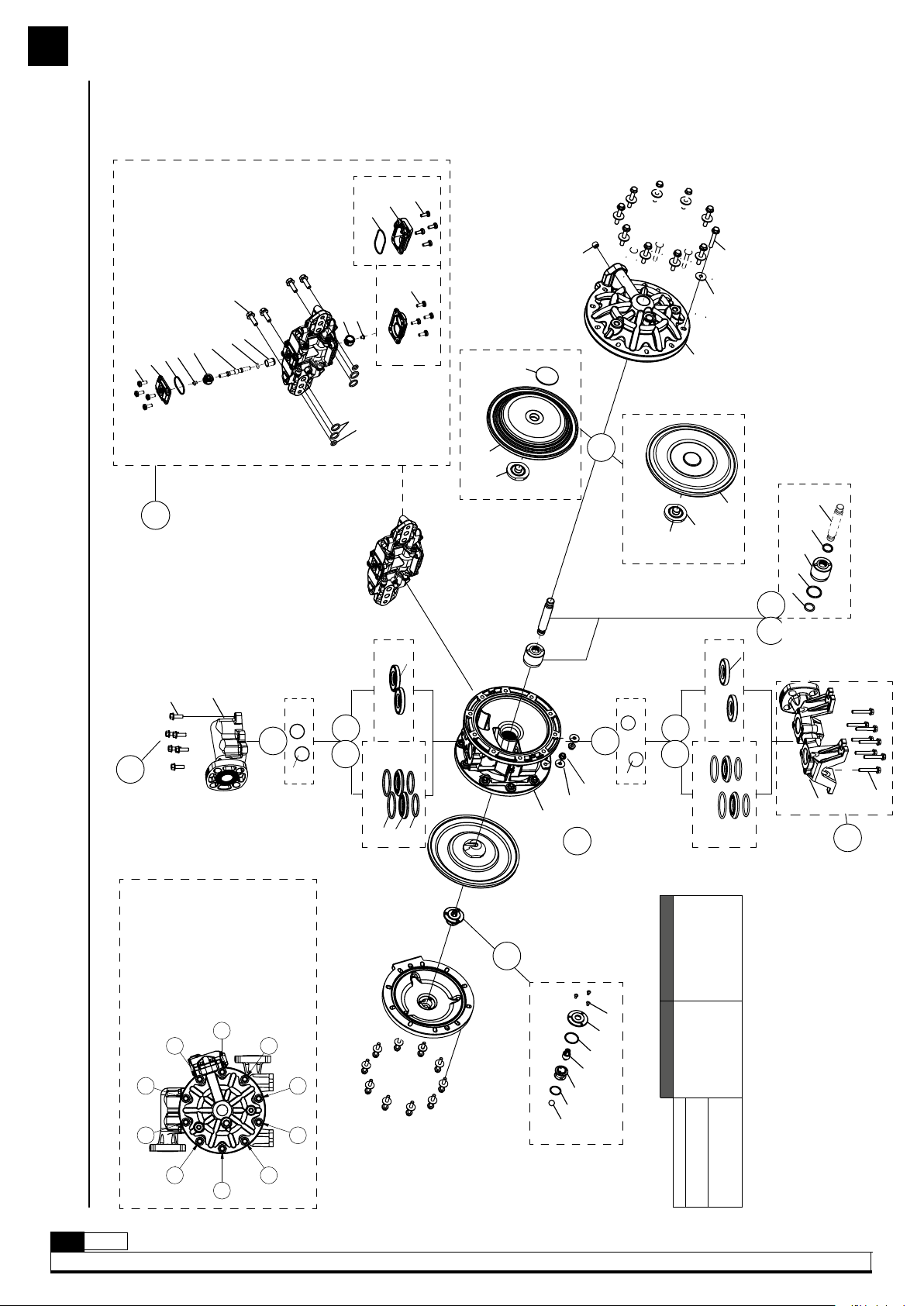

Air operated double diaphragm pumps are air-powered, reciprocating

positive displacement pumps with two pumping chambers. Two

diaphragms, centrally located in the chambers, separate the compressed

air (dry side) from the fluid being pumped (wet side). A shaft transmits the

reciprocating motion of one diaphragm to the other. A directional valve

alternatively distributes the air from one chamber to the other; thus a

reciprocating movement of the diaphragms is created. With each stroke,

fluid is discharged by one of the diaphragms whilst the opposite

diaphragm sucks new fluid into the expanding chamber. Check valves,

two on the discharge side and two on the suction side, control and direct

the fluid flow.

MATERIAL TEMPERATURE RANGE

PTFE 5 ºC - 105 ºC / 41 ºF - 221 ºF

NBR 10 ºC - 80 ºC / 50 ºF - 176 ºF

Acetal 10 ºC - 90 ºC / 50 ºF - 194 ºF

Hytrel®10 ºC - 90 ºC / 50 ºF - 194 ºF

Neopreno -18 ºC - 93 ºC / 0 ºF - 200 ºF

Santoprene®-29 ºC - 135 ºC / -20 ºF - 275 ºF

Viton®-10 ºC - 177 ºC /-4 ºF - 351 ºF

Polypropylene 10 ºC - 80 ºC / 50 ºF - 176 ºF

DESCRIPTION

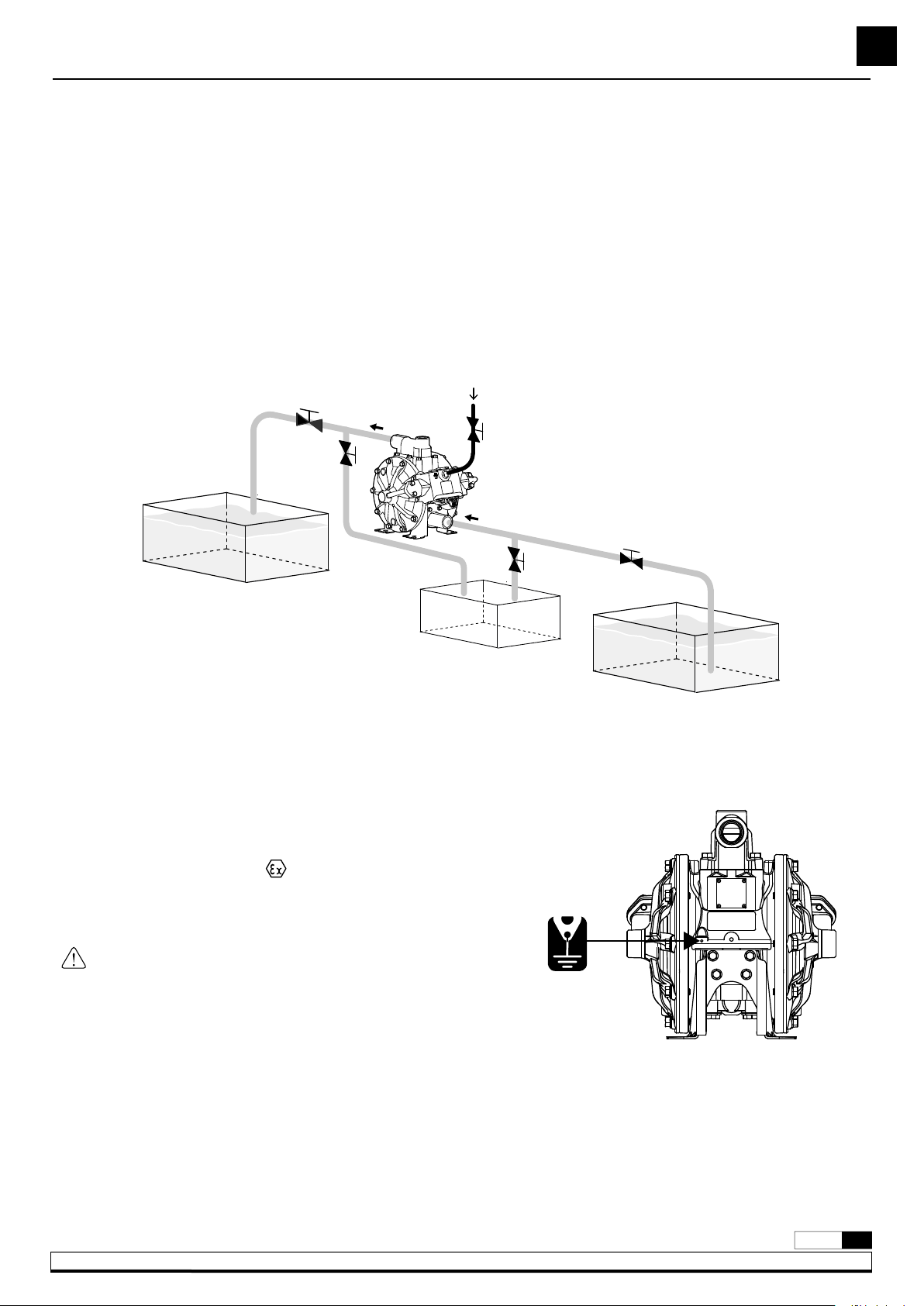

• Remove the pump from its package and install it on the chosen location.

• Try to minimize the suction head. Install the pump as close as possible to the fluid being pumped.

• Remember to have enough space around the pump to perform maintenance tasks.

• Keep in mind to connect the inlet and outlet of the pump correctly.

• In case of diaphragm pump failure, the air exhaust will expel the product being pumped.

• When the pump is installed in a place where a spill of fluid can cause an environmental impact, the exhaust should be directed to a place.where

this spill could be contained.

• When installing the pump in its place, use brackets to secure its base.

• Fasten all bolts with the torques contained in this manual.

INSTALLATION RECOMMENDATIONS

INSTALLATION