2 2016 Oventrop

“Akt r T ST”

Electr thermal actuat r (0-10 V)

Stroke – control voltage characteristic line

(max. piston stroke without valve)

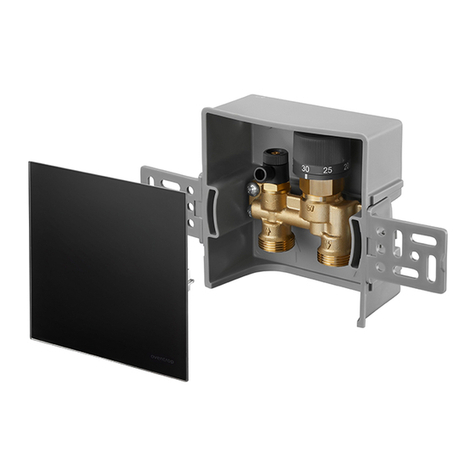

The actuator is mounted with the help of the valve adapter, no

tools are required. The valve adapter is manually screwed onto

the valve and the actuator is fixed to the adapter by use of the

plug-in connection.

The Oventrop electrothermal actuator can be installed in any

position but a vertical (stroke index pointing upwards) or

horizontal installation is preferable. In case of vertical downward

installation, special circumstances (e.g. dirt water) may reduce the

service life.

Applicati n:

The Oventrop electrothermal actuator (0-10 V) is used for heating,

ventilation and air-conditioning. In combination with the Oventrop

thermostatic radiator valves or the regulating valves “Cocon/

Hycocon” and the Oventrop room thermostat or a central

controller in the building technology, the actuator allows an

individual room temperature control.

The actuator can be combined with the following Oventrop valves

with connection thread M 30 x 1.5:

- Thermostatic radiator valves, all series (except for “Series

ADV 9, ADV 6 and KTB”)

- Three-way conversion valves

- Distributors/collectors for surface heating systems (please

observe ambient temperature within the cabinet)

- Regulating valves “Cocon 2TZ / QTZ”

- Regulating valves “Hycocon ETZ/HTZ”

- Three-way diverting and mixing valves

Functi n:

The Oventrop actuator works with an expansion type working

element which is heated electrically by a PTC heating element. A

silent operation and low power consumption are thus guaranteed.

Due to the “First-Open” function, the actuator is supplied open

with current “off”. This allows the operation of the heating system

during construction work even if the electric wiring of the

individual room temperature control has not yet been terminated.

T guarantee c rrect functi ning f the actuat r, it sh uld be

fitted t the valve bef re initial perati n. The “First-Open”

function is released automatically by switching the operating

current of 24 V AC (more than 10 min.) on for the first time. (This

happens only once during initial operation. After initial operation,

the actuator immediately switches to control operation each time

the operating current has been switched off.) After initialisation,

the upper valve lift position and the closing point of the valve are

determined by the actuator and the active control voltage range

is adapted to the determined valve travel. The actuator now

switches to control operation. The stored values are monitored

during operation, are adapted if required and are used for control

demands and positioning after having switched off the operating

current. This way, an optimum adaptation to the respective valve

is guaranteed.

If a control voltage of 0.5 – 9.5 V DC is applied after the closing

point has been determined, the actuator opens the valve (after

termination of the idle time) by lifting the spindle proportionally to

the control voltage. Within the range of 0 – 0.5 V, the actuator

remains in the idle position to ignore ripple voltage caused by long

cables. Within a range of 9.5 and 10 V, the spindle travels the

entire 5 mm to check the valve travel which is recognised

automatically. By reducing the control voltage and after

termination of the rest period, the valve is closed constantly by

the closing pressure of the pressure spring.

If the Oventrop actuators are used for room temperature control,

it is recommended to carry out the room temperature setback via

the room thermostat.

If for some reason a setback of the flow temperature is required

during night hours or at other times, a setback of the room

temperature via the room thermostat should be carried out

additionally.

Access ries Item n .:

Room thermostat (heating and cooling) 1152151

Room thermostat (heating and cooling) 1152153

with fan drive

Reinforcing cap 1012450

Valve adapter, M 30 x 1.0 1012890

Valve adapter, high model, M 30 x 1.5 1012462

R m therm stat

(heating and cooling)

with one proportional outlet 0-10 V

each for heating and cooling (can be

used for four pipe systems).

Setting of the nominal value via

the rotary knob, adjustable

idle time. Item no. 1152153

with additional three-stage fan

drive.

Reinf rcing cap

to protect the electrothermal

actuators against vandalism.

Valve adapter

connection thread M 30 x 1.0

(for Oventrop valves manufactured

up to 1998)

Valve adapter

high model,

connection thread M 30 x 1.5

(11 mm higher than standard)

Stroke – control voltage characteristic line with recognised valve

spindle lift (e.g. “Series A”)

Control voltage [V]

Piston stroke [mm]

Control voltage [V]

Piston stroke [mm]

Piston stroke

(Valve lift = 100%)

Travel

Subject to technical modification

without notice.

Product range 1 Gedruckt auf chlorfrei

ti 334-EN/10/MW

Edition 2016 gebleichtem Papier.

OVEN ROP GmbH & Co. KG

Paul-Oventrop-Straße 1

D-59939 Olsberg, Germany

Phone +49 (0)2962 82-0

Fax +49 (0)2962 82-450

E-Mail mail@oventrop.de

Internet www.oventrop.de

For an overview of our global presence

visit www.oventrop.de.