Regudis W-HTE

Safety-related information

• Maintenance

• Removal and disposal

Due to their professional training and experience as well

as knowledge of the relevant standards, specialist sanitary,

heating and air-conditioning tradespeople are able to carry

out work on heating, cooling and potable water

installations.They must be able to recognise possible

dangers independently.

Operator

The following work may be carried out by the operator:

• Operation of the product

The operator must be instructed in the operation of the

product by specialist tradespeople.

2.6.2 Danger to life due to electric current

Work on the power supply may only be carried out by a

specialist electrician. Opening the connection box is only

necessary for installing accessories.

!

Disconnect the station from the power supply at

all poles and secure it against being switched on

again.

!

Check that no voltage is present.

!

Only install the product in dry indoor areas.

2.6.3 Danger to life due to legionella

formation

!

Ensure the following:

• The temperature of the potable water in the cold

water pipe must not exceed 25 °C.

• The water in the potable water circuit must be

completely replaced after 72 hours at the latest.

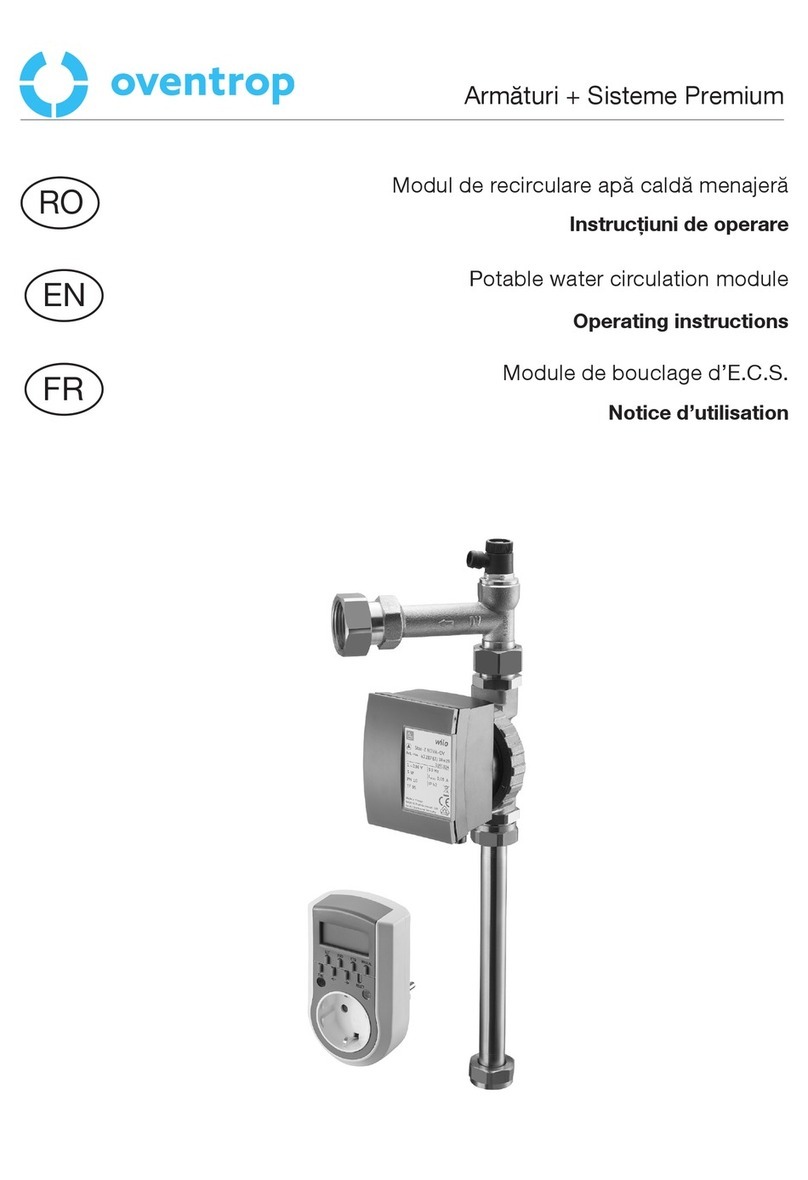

• When using the potable water circulation module, the

hot water temperature must be at least 60 °C.The

temperature difference between the hot water outlet

of the heat exchanger and the return of the circulation

pipe at the station must not exceed 5°C.

Observe the relevant regulations (e.g. DVGW

worksheet W).

2.6.4 Risk of scalding due to hot water

Due to adjustment or defect of the actuator, the hot water

temperature at the draw-off points can rise up to the

heating water temperature in the buffer storage cylinder.

!

If there is a risk of scalding in accordance with

DIN EN 806 and DIN 1988 due to high heating

water temperature in the buffer storage cylinder,

you must install scald protection at all draw-off

points.

!

If the heating water temperature in the buffer

storage cylinder is low, resulting in a low hot

water temperature without risk of scalding

at the draw-off points,you must instruct the

system operator to ensure the low heating water

temperature in the buffer storage cylinder all year

round.

2.6.5 Risk of injury from pressurised

components

!

Only carry out work on the heating circuit or

the potable water circuit when the system is

depressurised.

!

Adhere to the permissible operating pressures

during operation.

!

Install a safety valve that cannot be shut off in

the potable water heating installation (regulation

according to DIN EN 806-2).

2.6.6 Risk of burns due to unintentionally

escaping hot media

!

Only carry out work on the heating circuit or

the potable water circuit when the system is

depressurised.

!

Allow the product to cool down before working

on it.

!

Check that the product is not leaking after work

is complete.

!

Wear safety goggles.

2.6.7 Risk of burns on hot components and

surfaces

!

Allow the product to cool down before working

on it.

!

Wear suitable protective clothing to avoid

unprotected contact with hot fittings and plant

components.

2.6.8 Risk of injury due to weight of the

product

!

Always wear safety shoes during installation.

2.6.9 Risk of injury from improper work

Stored energy, angular components, points and corners on

and in the product can cause injuries.

!

Ensure there is sufficient space before starting

work.

!

Handle open or hard-edged components with

care.

!

Keep the working area tidy and clean to avoid

sources of accidents.

2.6.10 Damage to property due to unsuitable

location

!

Do not install the product in rooms prone to

frost.

!

Do not install the product in rooms with

corrosion-enhancing ambient air.

!

Observe the notes on corrosion protection in the

appendix.

9134403082-V09.03.2022