©2013 PACE Worldwide, Southern Pines, North Carolina All Rights Reserved Page 2 of 18

INDEX

TITLE

PAGE

GeneralInformation

Introduction.......................................................................................

3

Specifications....................................................................................

3

EOS / ESD...................................................................................4

Capabilities .......................................................................................

4

MBT 301 Compatible Handpieces...............................................4

HandpieceTips............................................................................4

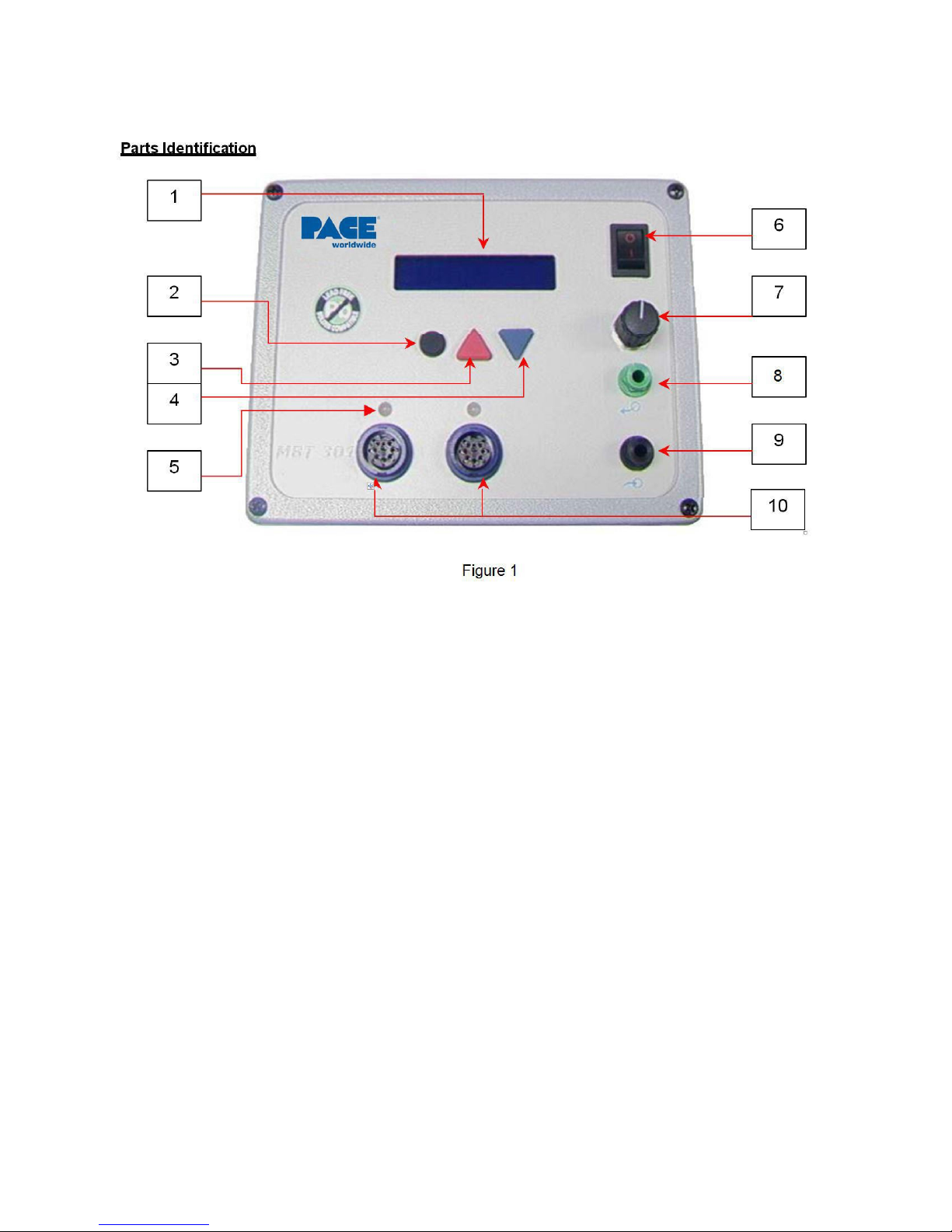

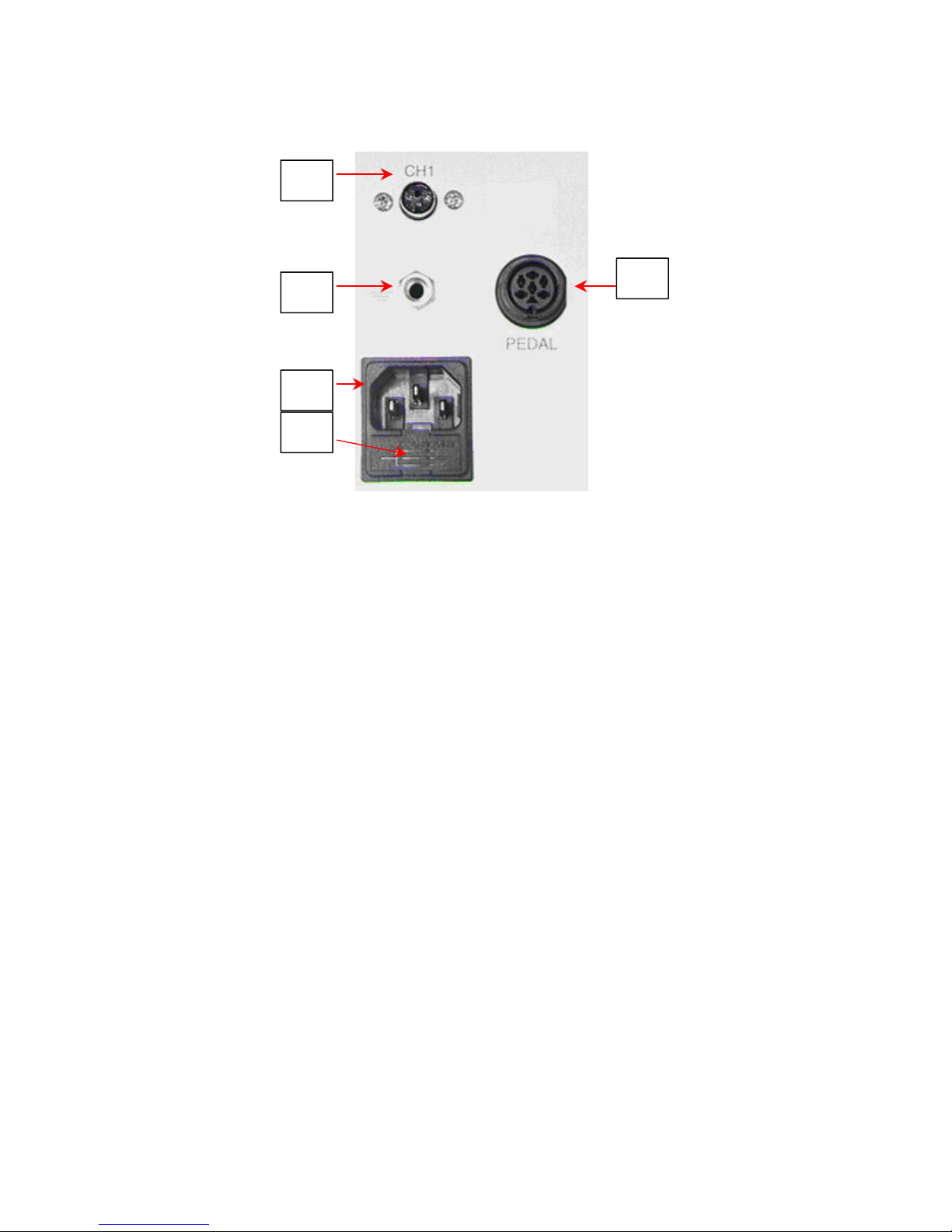

PartsIdentification .................................................................................5

SafetyGuidelines...................................................................................7

Safety........................................................................................................

8

UsageWarnings/Cautions...........................................................8

ServicingPrecautions..................................................................9

System Set-Up.......................................................................................9

Attaching Tip & Tool Stand.........................................................11

Instant Set Back Cubby..............................................................11

Tip Removal................................................................................11

Definitions...................................................................................................

12

System Power Up................................................................................12

LEDOperation......................................................................................13

Operation....................................................................................................

13

AccessingProgrammingMenu...................................................13

PasswordMenu..........................................................................13

Setting Temperature C /F ..............................................................13

Set Upper Limit...........................................................................14

Set Lower Limit...........................................................................14

Setback Time..............................................................................14

Set Auto Off ................................................................................14

Scan Enable / Disable.................................................................14

THC Calibration Offset Mode Select..........................................14

Set LCD Contrast........................................................................15

Set LED Backlite.........................................................................15

Exiting the Programming Menu ..................................................15

TemperatureAdjust Mode....................................................................15

Setting Channel Offset..........................................................................15

THC Tip Calibration ..............................................................................16

HelloMessage......................................................................................16

CorrectiveMaintenance........................................................................17

Packing List...........................................................................................17

Spare Parts...........................................................................................17

Service........................................................................................................

17

LIMITEDWARRANTYSTATEMENT...................................................18

ContactInformation...............................................................................18