©2004 PACE Inc., Annapolis Junction, Maryland Page 8 of 11

All Rights Reserved

The TEKLINK Remote Box (sold separately) allows the connection of up to three ST 25/45 systems in

any combination.

NOTE: Systems connected together through the TEKLINK system must be used and controlled by a

single operator. Any attempt to operate by more than one individual can create a hazard

condition and will cause deterioration in performance.

CAUTION: Ensure that only one air hose is connected to the VACUUM or controllable PRESSURE port

at one time. Attachment to both ports simultaneously will cause deterioration in performance.

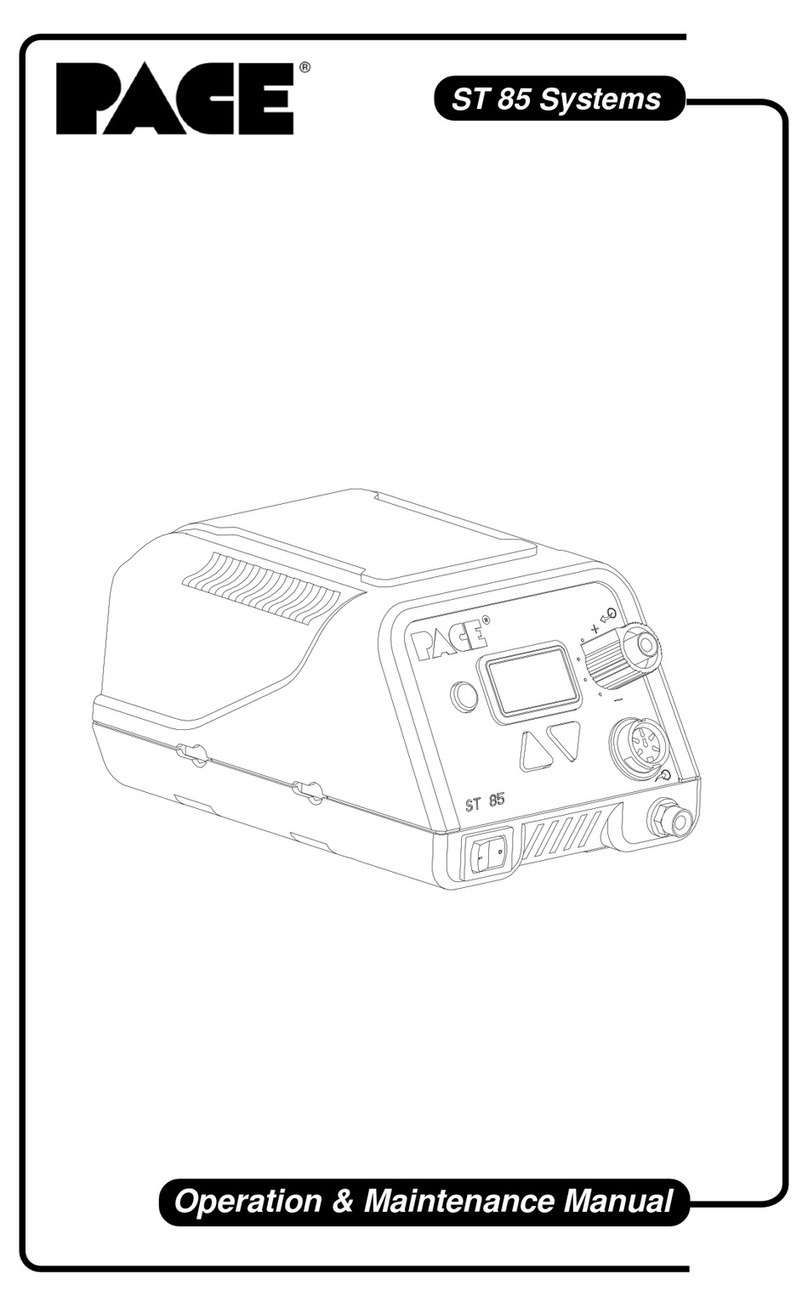

Temperature Dial Adjustment

The ST 25 system is tested for temperature accuracy at the factory and can be

checked for calibration according to PACE requirements. Also, a temperature setting

normally used by the operator can be adjusted to the precise temperature indicated on

the Dial/Display. No internal adjustments can be made to the power supply. To verify

calibration of the Temperature selection dial, perform the following procedure.

1. Install a tip with an embedded thermocouple into the handpiece connected to the system.

Tips with K type thermocouples are available from PACE.

2. Connect the thermocouple assembly to an appropriate temperature meter.

3. When set fully counterclockwise, the pointer of the Variable Temperature

Control knob will align to the Calibration Mark as shown. With the system

turned on, adjust the Variable Temperature Control to obtain a stable tip

temperature of 300°C (for PACE factory specifications) or the temperature

setting normally used by the operator.

If the temperature displayed on temperature meter is within ±15°C (27°F),

perform steps 4 thru 6 to obtain a precise reading. If the temperature is off by more than

±15°C, the handpiece may require maintenance. Recheck the temperature using a

second handpiece.

4. Carefully lock the Variable Temperature Control in position by tightening the

inner set screw (closest to front panel).

5. Loosen the outer set screw on the Variable Temperature Control knob (furthest

from front panel) using the Temp. Locking Key (hex key) supplied with the

system. Position the knob with the pointer aligned to match the temperature

indicated on the temperature meter. Secure the knob in position by tightening the outer

set screw.

6. Loosen the inner set screw to unlock the Variable Temperature control if adjustment of

operating tip temperature is desired.

Corrective Maintenance

Power Source

Most malfunctions are simple and easy to correct.

Symptom Probable Cause Solution

No power to

system Blown Fuse Check handpiece using the appropriate handpiece manual.

Replace the fuse (located in the AC Receptacle Fuse

Holder) with one of the same rated value.

Defective Heater Refer to the appropriate handpiece manualHandpiece will

not heat Power Source Malfunction Contact PACE

Power Source Corrective Maintenance