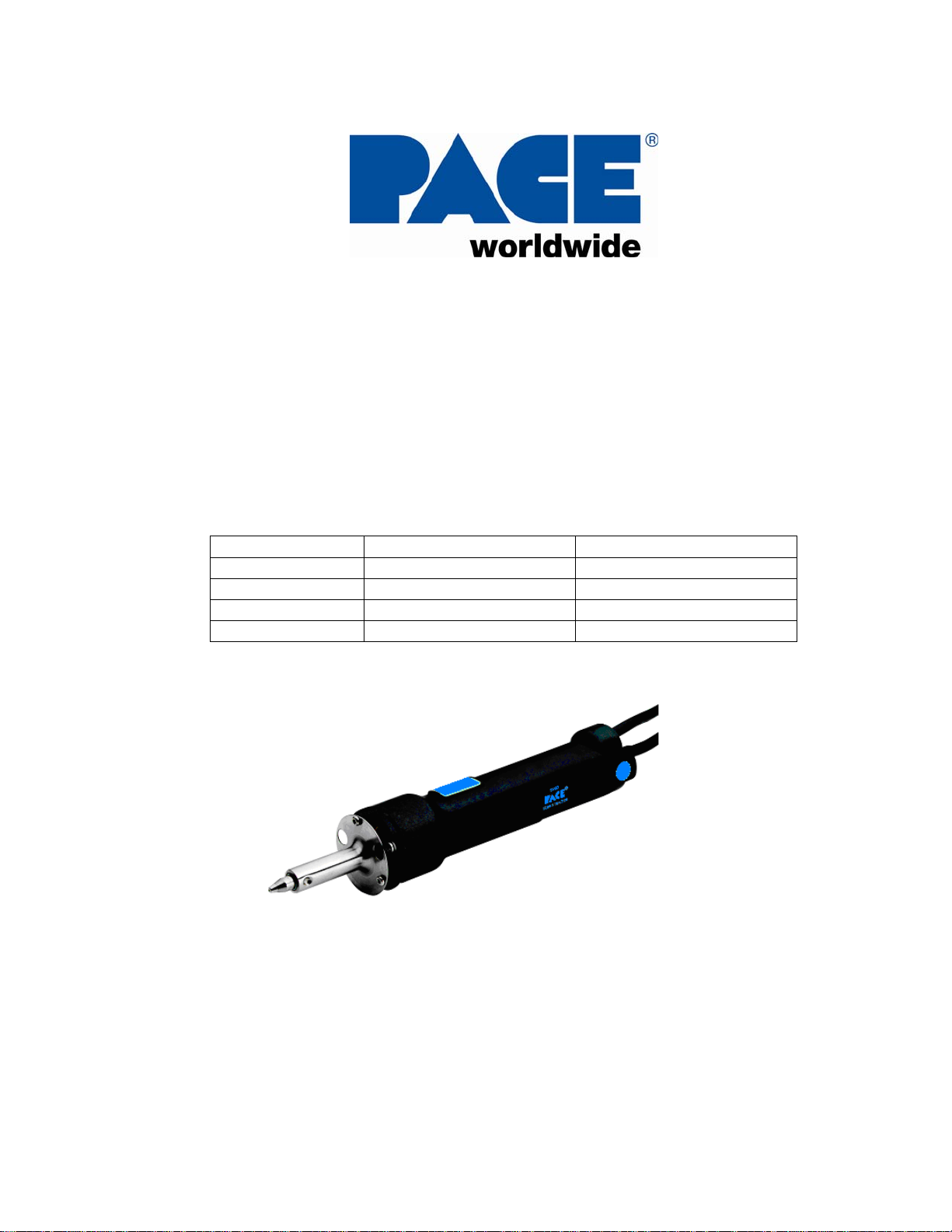

PACE Sodr-X-Tractor Handpiece

©2012 PACE Inc., Southern Pines, NC. All Rights Reserved Page 7 of 11

www.paceworldwide.com

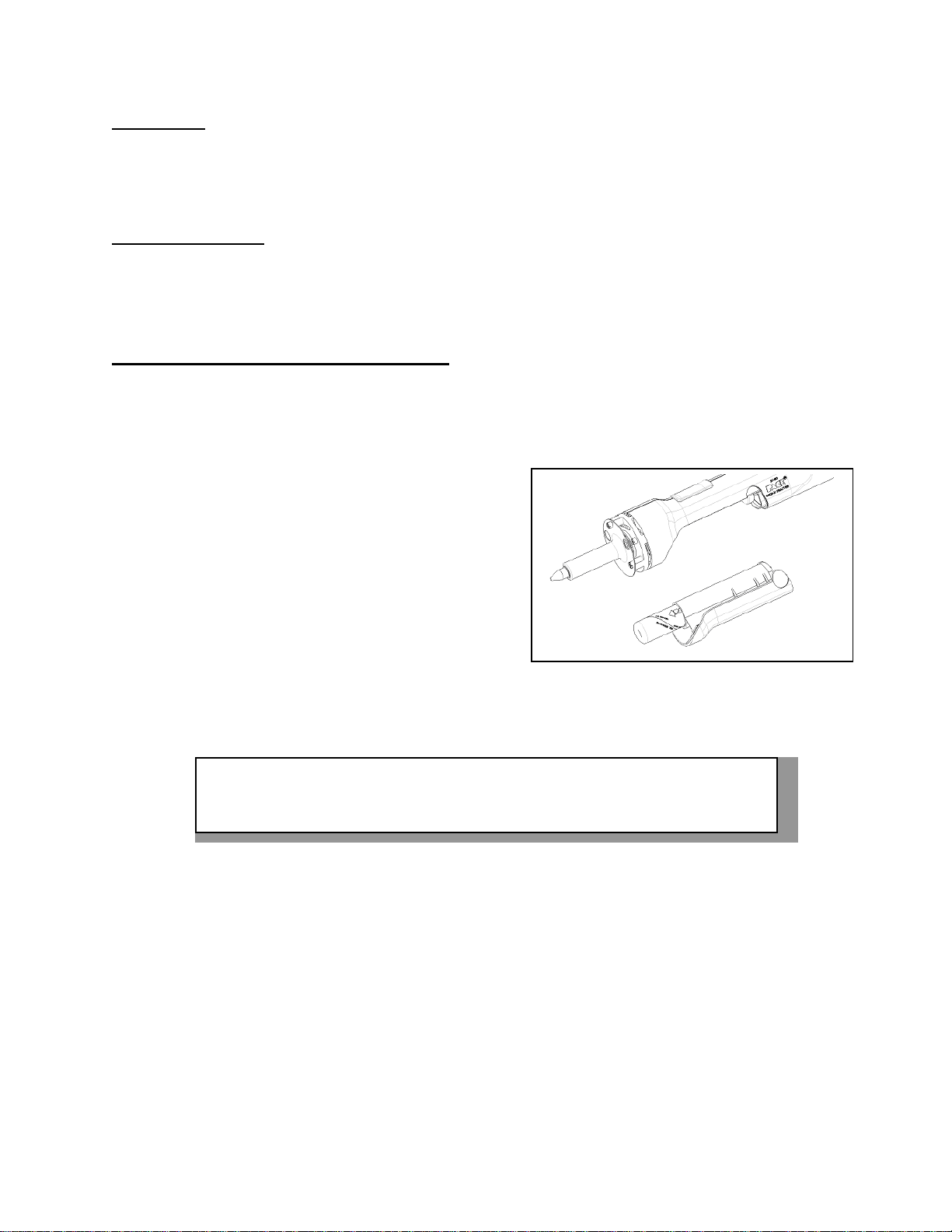

4. During Flo desoldering or Thru-hole desoldering, on heavily fluxed or contaminated boards, debris

may collect inside the tip bore. If this occurs, clean the tip bore with the Sodr-X-Tractor Tip Cleaning

Kit (PACE part number 6993-0200).

5. The Sodr-X-Tractor handpiece is now ready for use. If not immediately using the handpiece, store

in its Tip & Tool Stand.

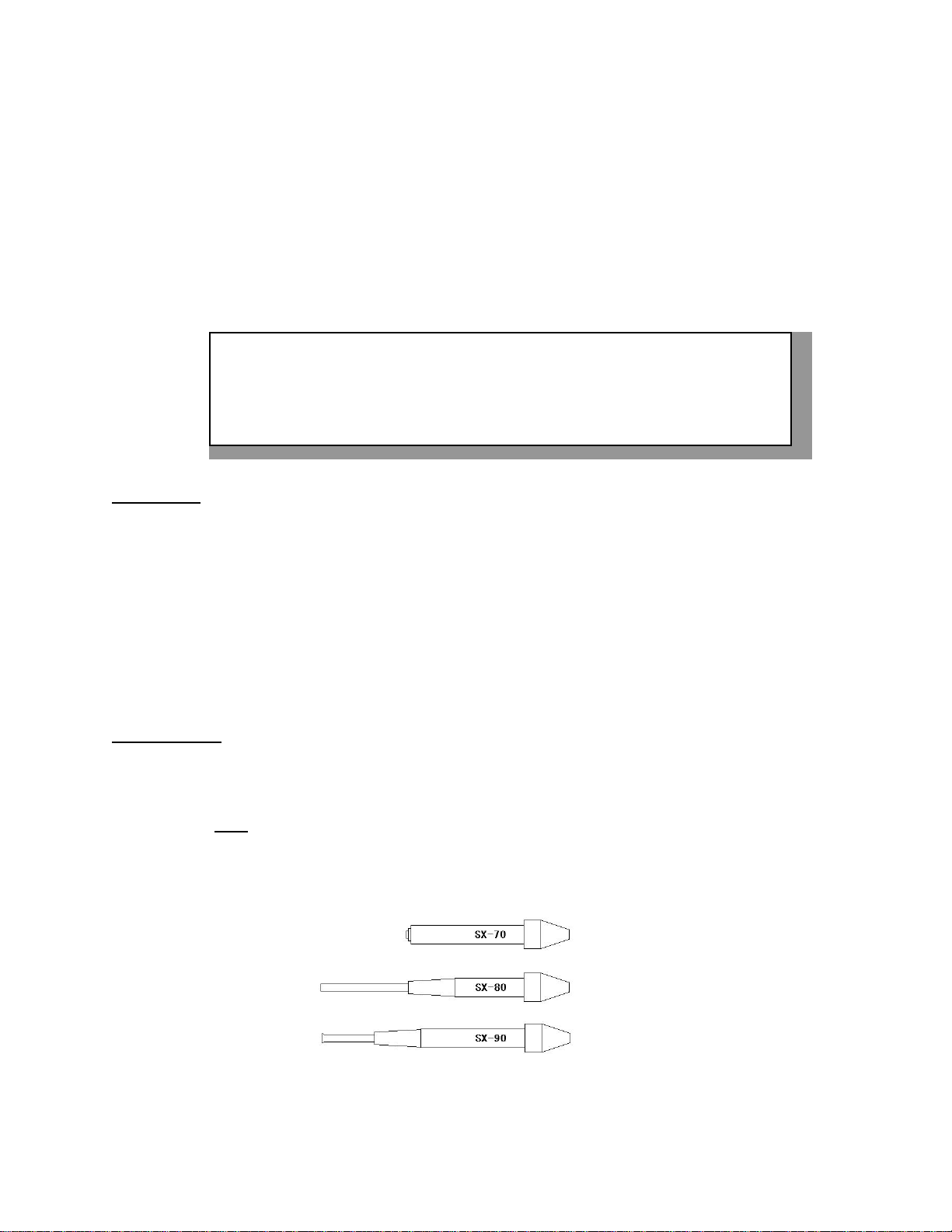

Through Hole Solder Extraction

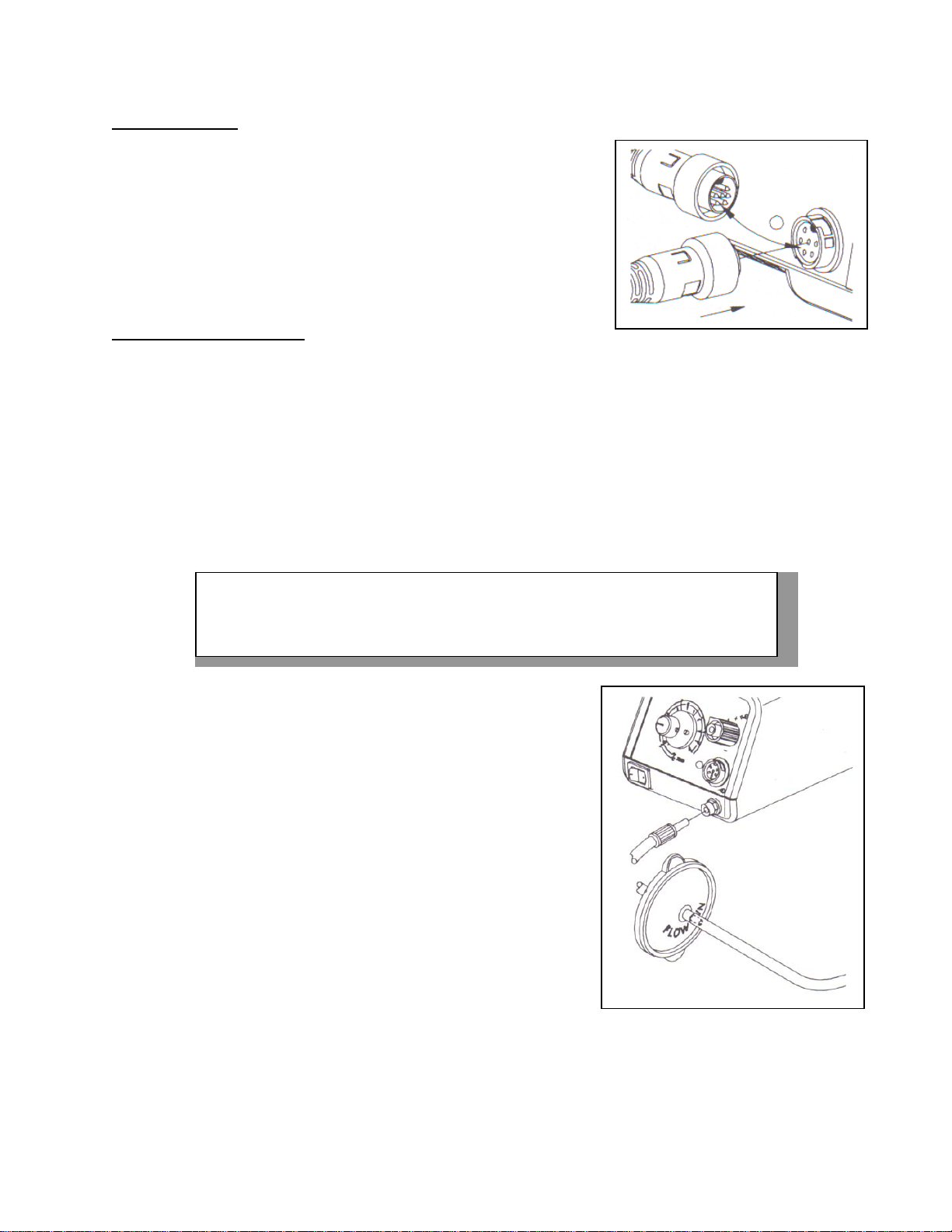

1. Ensure that the handpiece vacuum hose is connected to a VisiFilter and the Vacuum Port on the power

source. Select an operating temperature that will cause completesolder meltin 2-5seconds (somewhat

longer on heavy multilayer boards). A starting tip temperature of 316°C (600°F) is recommended for most

applications.

2. Position your index finger on the handpiece vacuum control switch.

3. Gently position the extractor tip over the lead contacting the solidified solder keeping tip perpendicular to

thepadand board. Do not apply pressure against the pad at any time during this operation.

Damage to the board may result.

4. Gently move the lead…..

a) In a circular motion for round leads

b) In a back and forth motion for flatleads

until the lead moves freely. Free lead movement indicates that completesolder melt has been obtained.

5. While continuing to move lead, actuate vacuum with the finger switchand keep on for at least 2 seconds to cool

joint and prevent re-sweating. The length of time from when heat is applied until the time vacuum is started (i.e.,

complete solder melt) should be 2-5 seconds under normal conditions.Heavymultilayerboards mayrequire

somewhat longer heating times. In extreme cases, preheating or auxiliary heating is recommendedtoachieve

thesafest results

.

6. Remove tip from pad and continue vacuum application for an additional 2 seconds to insure that all

residual solder is drawn into the solder collection chamber.

7. Re-tin tip using large gauge flux cored solder and return Sodr-X-Tractor to its Tool Stand.

8. After all leads are desoldered, the component is easily removed. If any solder should remain in the

plated thru-hole after extraction, resolder the connection and perform this procedure again.

NOTE

Ensure that the tool stand sponge material is moist and free of debris. Add water

if necessary. Wiping the heated tip on a dry sponge will only contaminate the tip

and ultimately the board.

NOTE

Early activation of the vacuum may result in incomplete removal of solder from

the joint being desoldered. Free movement of the lead is the work piece indicator

that proper solder melt has been achieved. In the event that all the solder has

not been removed from the hole, resolder the hole and try again after the board

has been allowed to cool.