Operating Manual

Thank you for your choice of Parker product. Please read this

operating manual carefully and use the product correctly. Keep this

operating manual in case questions arise about this product in the

future. If this operating manual becomes unreadable or lost, consult

our distributors or Parker sales offices.

For Safety Use

The following safety precautions are provided to prevent damage and

injury to personnel and to provide instructions on the correct usage of

this product. These precautions are classified into 3 categories:

“CAUTION”, ”WARNING”, and “DANGER” according to the severity

of possible injury or damage and the likelihood of such injury or

damage. Be sure to comply with all precautions. Also comply with

safety regulations such as ISO 4414(*1), Industrial Safety and Health

Law, and High Pressure Gas Safety Law.

Danger:

Indicates an impeding hazardous situation which may

arise due to improper handling or operation and could

result in serious personal injury or death.

Warning:

Indicates a potentially hazardous situation which may

arise due to improper handling or operation and could

result in serious personal injury or death.

Caution:

Indicates a potentially hazardous situation which may

arise due to improper handling or operation and could

result in personal injury or property-damage-only

accidents.

*1 ISO 4414: Pneumatic fluid power recommendations for the application of equipment to

transmission control system.

● This product is designed for air blowgun.

Do not use it for other purposes.

●

Use compressed air from an air compressor.

Do not use air from a high pressure tank or any other gases.

● Do not blow air from air blowgun towards

personnel or animals.

Direct air blow or substance blown by air blow can potentially

cause injury for humans or animals.

● Wear safety glasses and ear plugs.

Regardless of the use of this product, wear safety glasses and

earplugs when operating an air blowgun. Without proper

protection, injury to eyes due to blown dust or noise induced

deafness would be potentially caused.

● Do not disassemble or modify this product.

Disassembling or modification may cause safety accidents in

addition to operation failure.

● Attach a pipe fitting or joint properly.

If a pipe fitting or joint are attached improperly, it may cause

danger such as hose whip due to unplugged piping. Confirm the

connection of hose, tube or coupler joint is tight as well as the

connection to this product prior to use.

● Do not use for medical equipment or cooking

equipment

This product contains a small amount of lubricant. If there is

concern for contamination due to lubricant, do not use.

Specifications

Fluid Compressed air

Pressure Range 3.5 to 8 bar

Maximum Flow

*1

1300L/min (@5 bar)

Ambient Temperature

*2

10 to 50 degree C

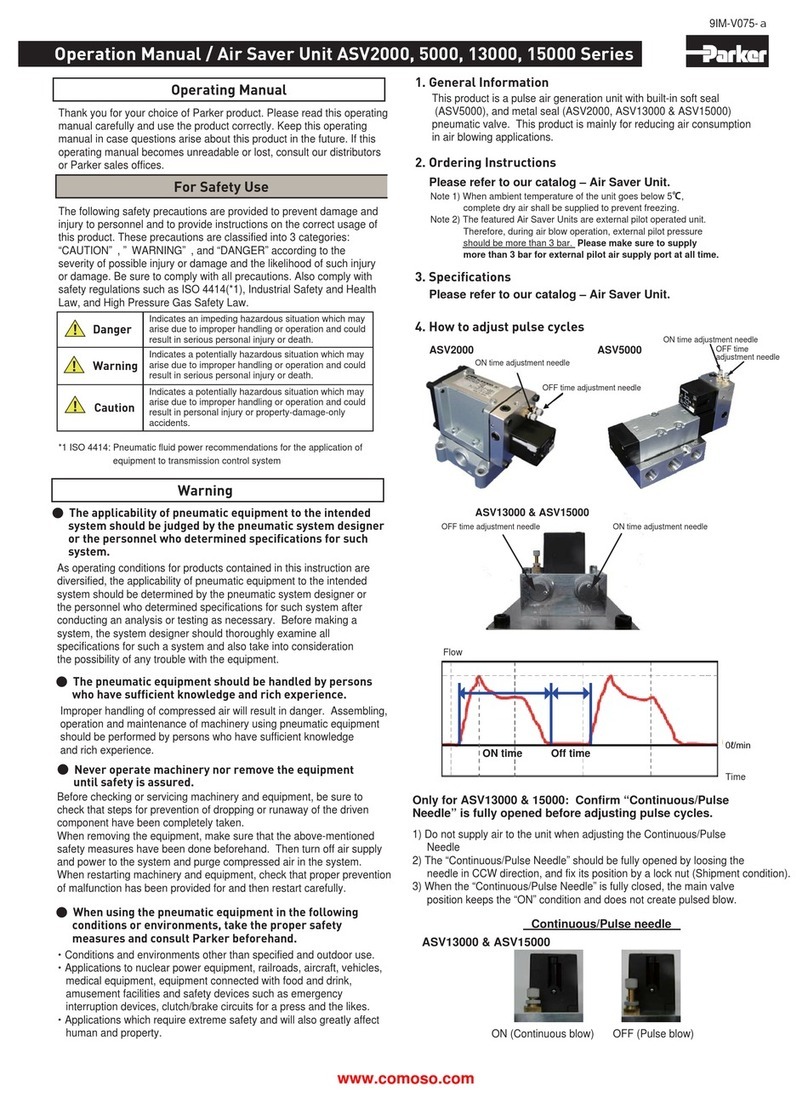

Pulse Adjustment Range 5 to 15Hz

Port Size

IN

Rc1/4 (BSPT1/4)

OUT

R1/4 (BSPT1/4)

Weight 155 g

*1 “Maximum Flow” indicates the flow capacity of this product, and

actual flow consumption is depending on the attached air blowgun.

*2 If the temperature is under the specified temperature, pulse blow

may become unstable. Please use it as continuous blow

temporally for a while to reach specified temperature. This product

works correctly within the specified ambient temperature.

Connection

1. Before Piping, thoroughly flush the inside of each pipe to

remove chips, machining oil, and dust etc. If sealing tape is

used for the thread, leave 1.5 to 2 thread turns unwrapped. Do

not use liquid sealant. It has possibility to contaminate the

product and may cause malfunction.

2. When installing piping or a joint, prevent penetration of chips or

sealing agent. Also tightening torque should be within the range

Warning

Bits of seal tape may enter

the flow passage and cause

malfunction.

Leave space of 1.5 -2 turns

It can be used by

cutting in half.

Cut with knife.

Not good

Good

Air Saver Unit for Air Blowgun

“Air Saver Module” HASV08R

9IM-E009-a

Issued:Jan.15.2016

Air blowgun

“Air Saver Module”

HASV08R

Reference blowgun:

Parker LEGRIS

Part Number: 0659 00 13

(Sold Separatel