1. Carefully spin off filter with

bowl, then fill with clean fuel

(useastrapwrenchneartopof

spin-onfiltertoremoveit).

2. Spinfilterwithbowlonto

mounting head and tighten

snugly by hand—do not use

tools to tighten.

3. Startengineandcheckfor

leaks.Ifengineisdifficultto

startorrunsrough,checkthat

drain, bowl, filter, and port plug

aresecurelytightened.Check

all connections for security

and hoses to ensure there

arenokinksorsharpbends

that would create excessive

restriction.

Danger! When servicing gasoline

fuel systems, extreme care must

be exercised to avoid potential

fire hazards. Do not smoke or

permit open flames near fuel

during servicing procedures.

Draining The Bowl

Water is heavier than fuel and

will settle at bottom of bowl

andappeardifferentincolor.In

extremelyhumidconditions,take

afuelsample(inclearcontainer)

frequently, and drain as required if

water is present.

1. Placeasuitablecontainer

below unit to collect

contaminants.

2. Closefueltankvalve,if

applicable, then open self-

ventingdrain(-01model)or

loosen/removedrainplug(-02

model)atbottomofbowl.

Note:aULListeddrainvalve

kitisavailablefor-02models,

orderpartno.RK19492.

3. Primefuelsystemfollowing

the manufacturer’s procedure -

refertoPriming.

Danger! Great care must be

exercised to avoid potential fire

hazards during installations on

gasoline fuel systems. Do not

smoke or permit open flames or

sparks near the fuel system.

Refer to Installation Diagram

on page 4 prior to beginning

installation.

1. Any secondary or pressure side

filters located between pump

and engine should be serviced

and left in place.

2. Mount unit vertically on suction

side of fuel pump, transfer

pump, or non-removable filters,

whichever comes first.

3. Ensure a suitable pipe thread

sealing compound is used on

NPTthreadsoffittingprior

toinstallationintohead.For

mounting flexibility, there are

two inlet ports and one outlet

port.Platedsteelfittingsare

recommended.Plugunused

portwithprovidedsteelNPT

plug—do not use tapes on

NPTthreads.

4. Usequalityfuelhosein

maximum fuel line size

applicable to reduce potential

fuelflowrestrictions.Note:

USCGacceptedhose

recommended.

Installation Guidelines

Service

Filter Replacement

Filterreplacementfrequencyis

determined by contamination

levelsinfuels.Fuelflowtoengine

becomes restricted as filter

slowly plugs with contaminants,

resulting in noticeable power loss

and/orhardstarting.Replace

filterannually,every500hours,

or when there is a noticeable

power loss, whichever comes

first. Change filter as soon as

possible. Note: always carry extra

replacement filters as one tankful

of excessively contaminated fuel

can plug a filter.

Clean any debris or dirt away from

Racorhead/filterjointpriorto

removal.

1. Placeasuitablecontainer

below unit to collect

contaminants.

2. Closevalveatfueltank,if

applicable, open or remove

drain(plug)toemptyfilterof

fuel.

3. Spinfilterandbowlofftogether

(useastrapwrenchonfilter),

then remove bowl from filter.

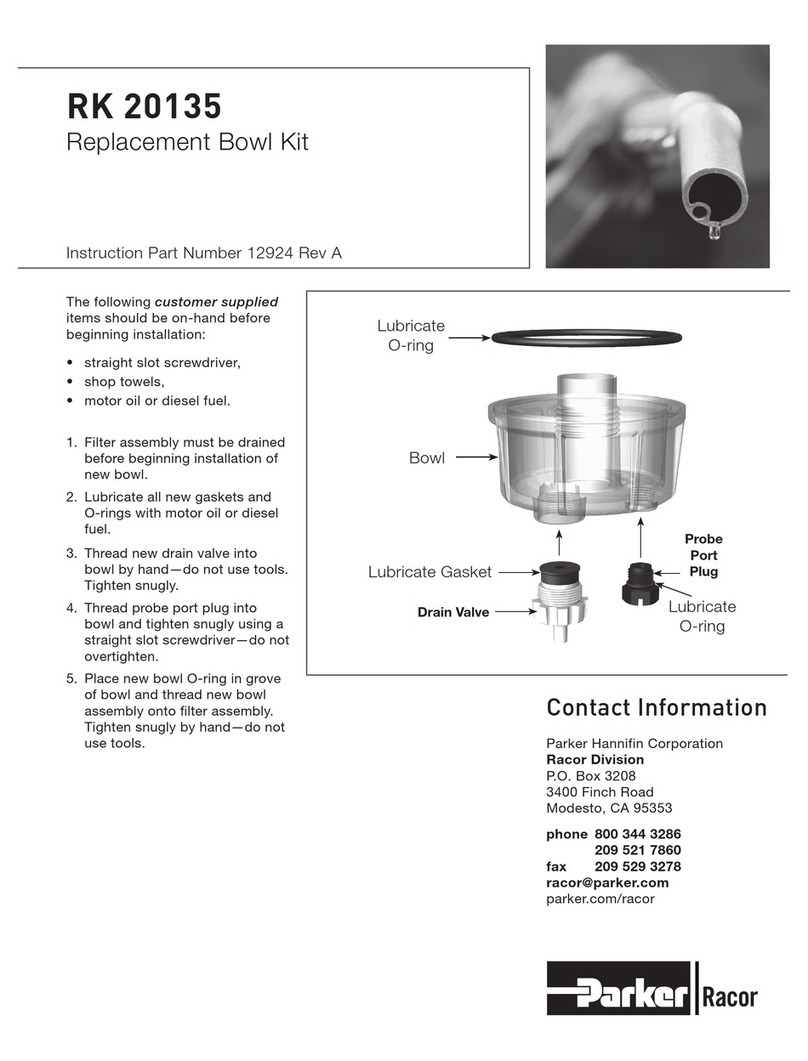

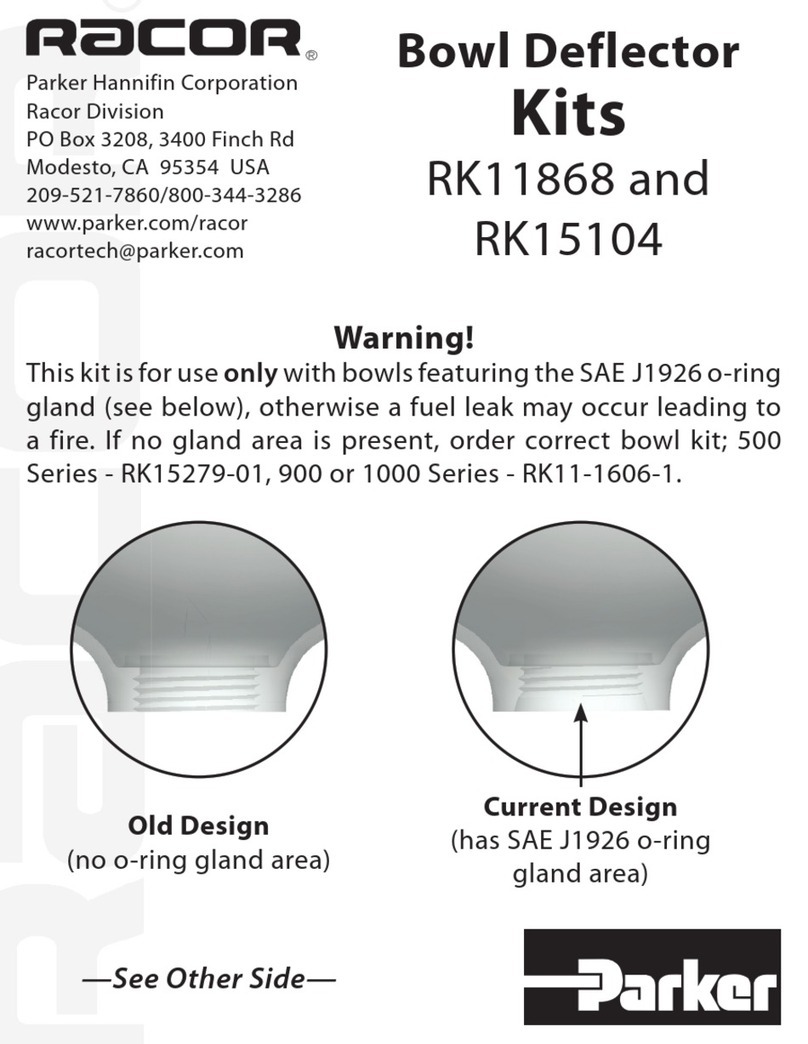

4. Clean,bowlO-ringglandand

sealing surface of mounting

head, of dirt, debris, or gums.

5. Apply lube oil to new seal and

bowlO-ringsuppliedwithnew

filter.

6. Placenewsealontotopof

newfilterandO-ringintobowl

gland.

7. Spinbowlontofilter,thenboth

ontohead.Tightensnugly

by hand – do not use tools to

tighten.

8. Primefuelsystemfollowing

manufacturer’s procedure -

refertoPriming.

Priming