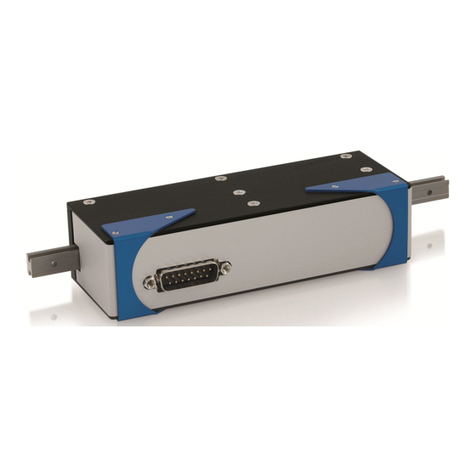

M-238 High-Load Linear Actuator MP77E Version: 1.1.0 3

2.1 Intended Use

The M-238 is a laboratory device as defined by DIN EN 61010-1. It is intended for indoor use

and use in an environment which is free of dirt, oil, and lubricants.

According to its design, the M-238 is intended for positioning, adjusting and shifting loads in

one axis at various velocities. The M-238 can be mounted horizontally or vertically.

It is only possible to use the M-238 as intended when it is installed and connected properly, and

only in conjunction with a suitable controller. The controller must be able to read and process

the signals from reference and limit switches, and from the incremental position sensors. The

controller is not included in the scope of delivery of the M-238.

2.2 General Safety Information

The M-238 is built according to state-of-the-art technology and recognized safety standards.

Improper use may result in personal injury and/or damage to the M-238.

Use the M-238 only for its intended purpose, and only when it is in perfect technical

condition.

Read the user manual.

Eliminate any malfunctions that may affect safety immediately.

The operator is responsible for the correct installation and operation of the M-238.

2.2.1 Organizational Measures

User manual

Always keep this user manual together with the M-238.

If the user manual is lost or damaged, please contact our customer service (see p.

The latest versions of the user manuals are available on our website (p. 2) for

download.

Add all information from the manufacturer such as supplements or technical notes to

the user manual.

If you give the M-238 to other users, include this user manual as well as all other

relevant information provided by the manufacturer.

Do the work only if the user manual is complete. Missing information due to an

incomplete user manual can result in minor injury and damage to equipment.

Install and operate the M-238 only after you have read and understood this user

manual.

Safety