1About this Document 1

1.1 Objective and Target Audience of this User Manual.................................................. 1

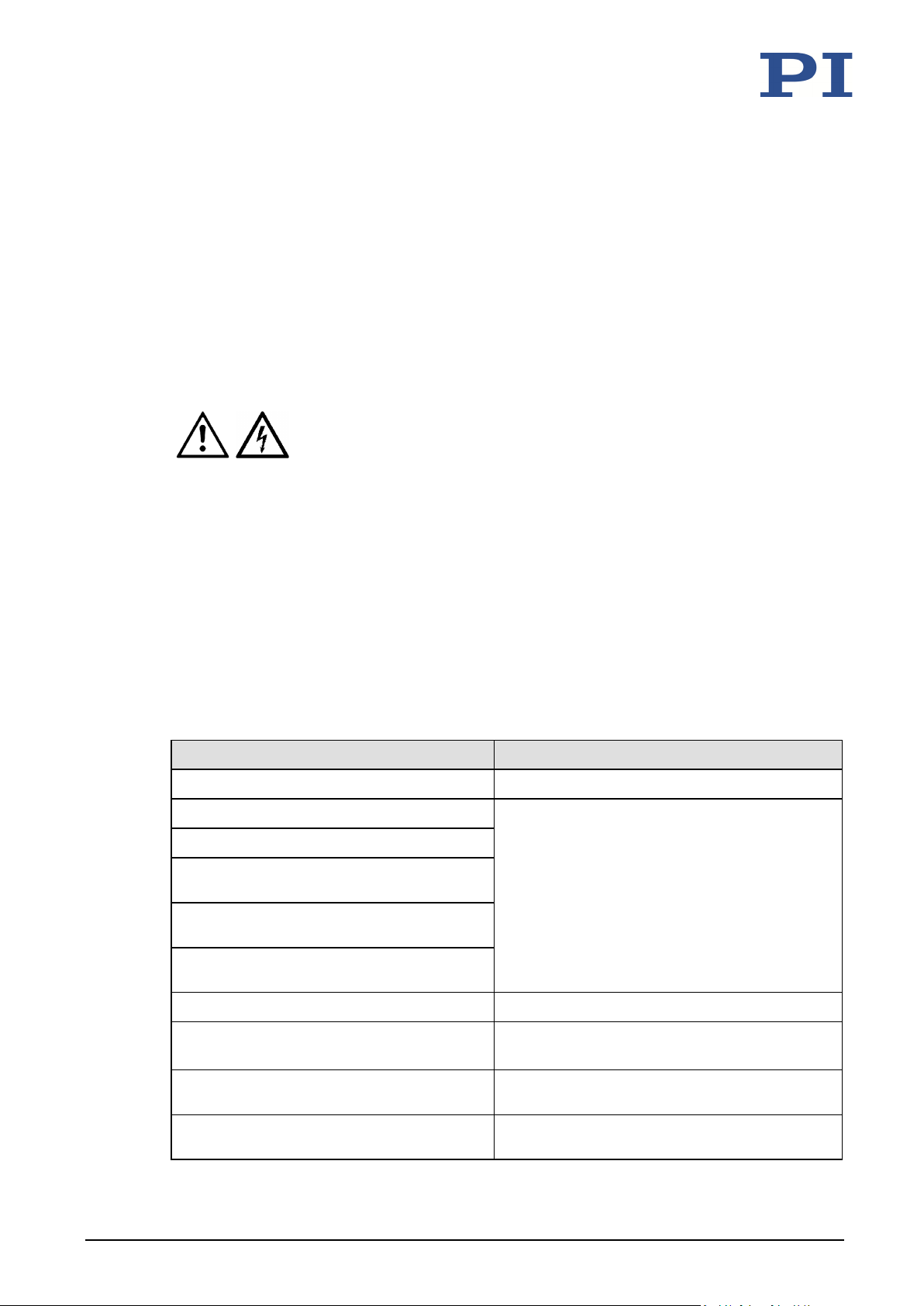

1.2 Symbols and Typographic Conventions...................................................................... 1

1.3 Figures ........................................................................................................................ 2

1.4 Other Applicable Documents ..................................................................................... 2

1.5 Downloading Manuals................................................................................................ 3

2Safety 5

2.1 Intended Use .............................................................................................................. 5

2.2 General Safety Instructions ........................................................................................ 5

2.3 Organizational Measures............................................................................................ 6

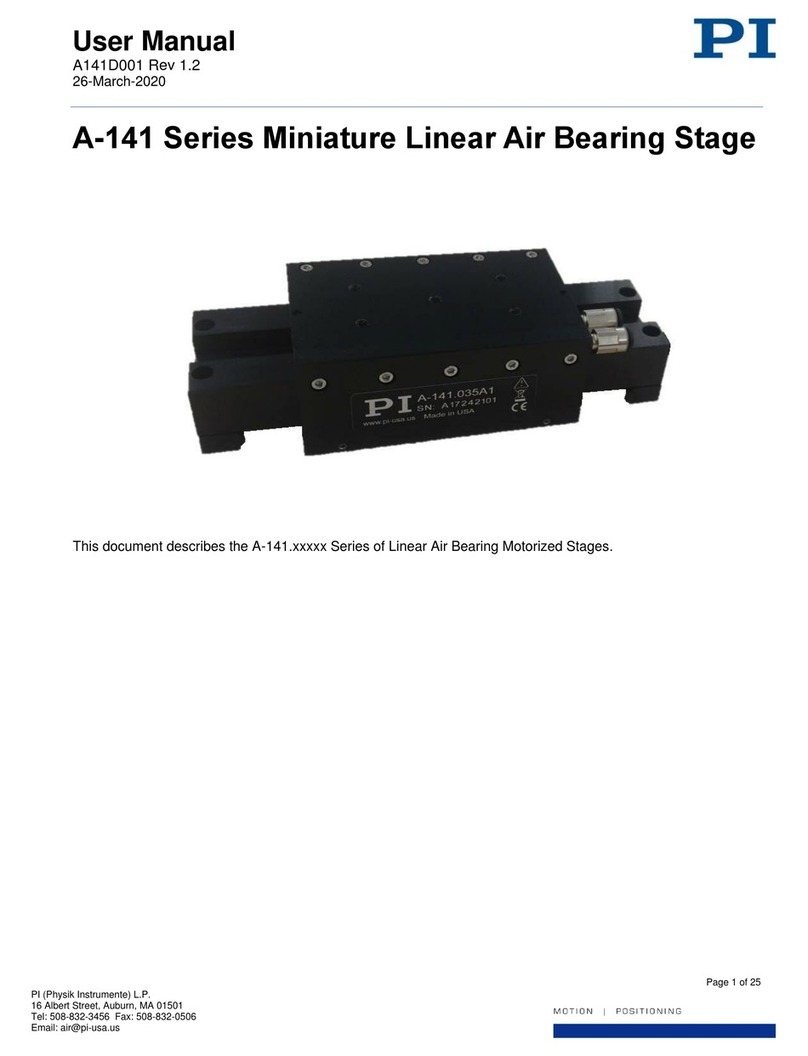

3Product Description 7

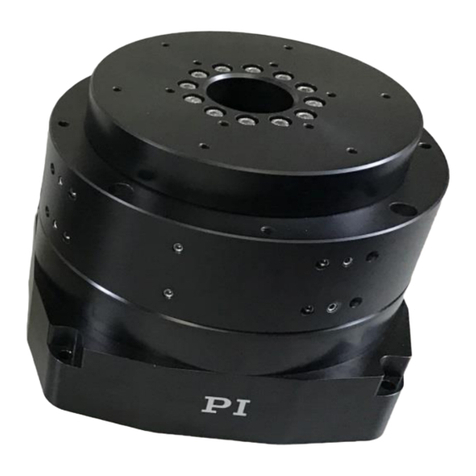

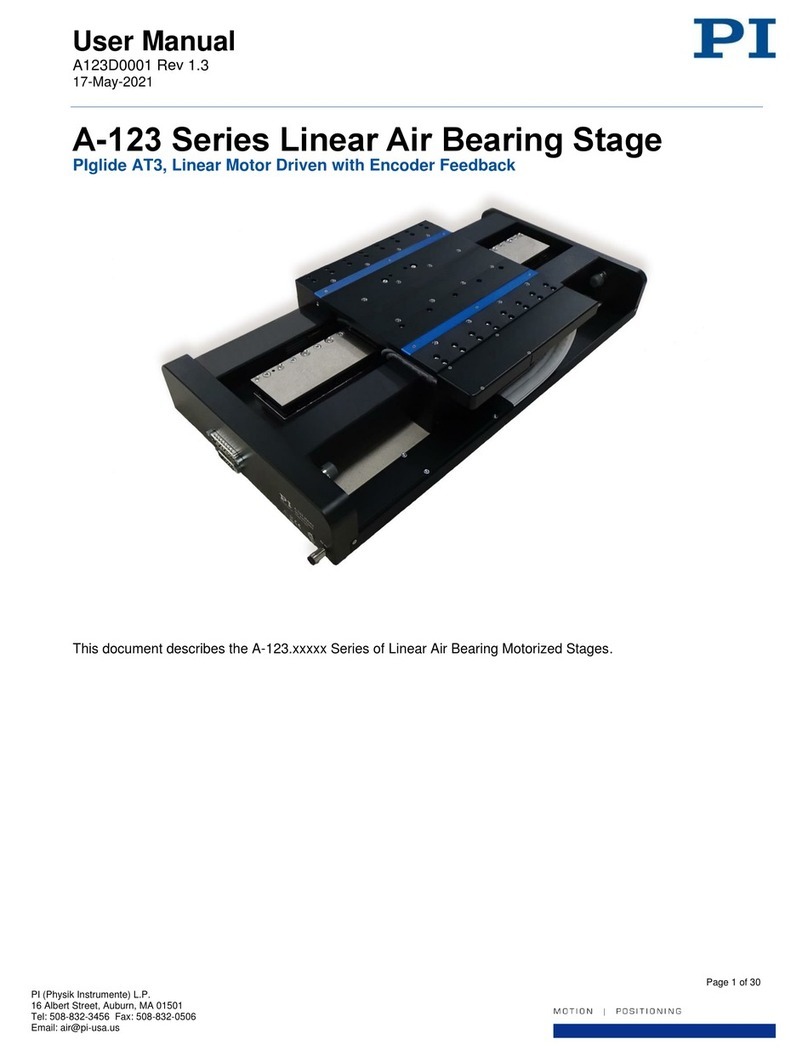

3.1 Model Overview ......................................................................................................... 7

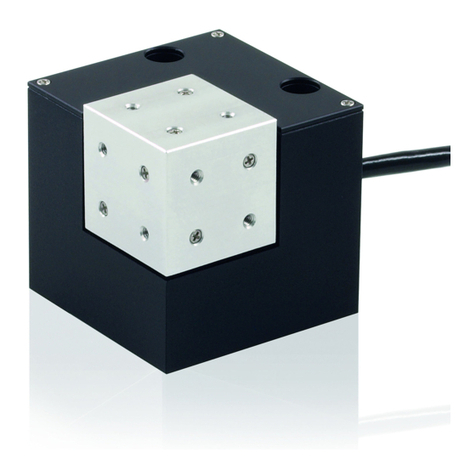

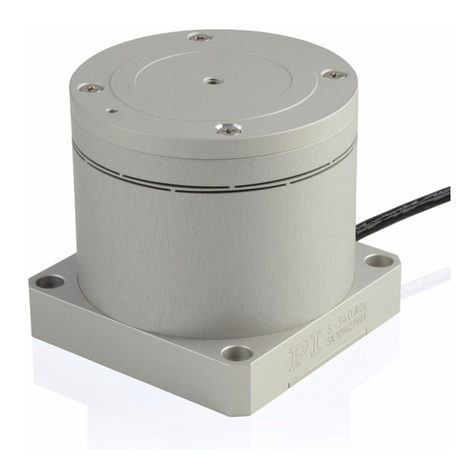

3.2 Product View .............................................................................................................. 8

3.3 Product Labeling......................................................................................................... 9

3.4 Scope of Delivery...................................................................................................... 11

3.5 Accessories ............................................................................................................... 12

3.6 Suitable Electronics .................................................................................................. 12

3.7 Control...................................................................................................................... 14

3.8 Dynamic Behavior..................................................................................................... 15

3.8.1 Calculating Moments of Inertia for Mirror and Mirror Holder.................... 16

3.8.2 Calculating the Resonant Frequency of the Tip/Tilt Platform..................... 19

4Unpacking 21

5Installation 23

5.1 General Notes on Installation................................................................................... 23

5.2 Mounting the Mirror on the S-340........................................................................... 25

5.3 Mounting the S-340.................................................................................................. 29

5.4 Connecting the S-340 to the Protective Earth Conductor........................................ 30

5.5 Connecting the S-340 to the Electronics .................................................................. 31

6Starting and Operating 33

6.1 General Notes on Starting and Operating................................................................ 33

6.2 Operating the S-340 ................................................................................................. 34

6.3 Discharging the S-340............................................................................................... 35

Contents